Production device and process for 3D flexible knurling nonwoven fabric

A production device and technology of non-woven fabrics, applied in textiles and papermaking, fabric surface trimming, thorn patterns, etc., can solve the problems of affecting product comfort and increasing the hardness of embossed non-woven fabrics, and achieve easy control and improvement of process conditions The effect of softness and simple production process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

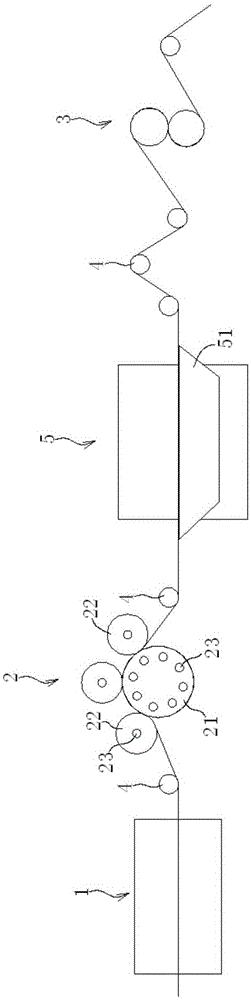

[0029] The production process of 3D flexible embossed non-woven fabrics includes the following steps:

[0030] (1), non-woven fabric is preheated through preheating device 1, and the preheating temperature of preheating device 1 is 65 ℃;

[0031] (2), the preheated non-woven fabric is embossed through the embossing device 2, the heating temperature of the embossing roller 21 is 128°C, and the heating temperature of the soft rubber roller 22 is 65°C;

[0032] (3), the embossed non-woven fabric is fluffed through the hot air blowing device 5, and the hot air temperature of the hot air blowing device 5 is 80°C.

[0033] (4) The embossed non-woven fabric is cooled by a cooling device, and then rolled.

Embodiment 2

[0035] The production process of 3D flexible embossed non-woven fabrics includes the following steps:

[0036] (1), non-woven fabric is preheated through preheating device 1, and the preheating temperature of preheating device 1 is 50 ℃;

[0037] (2), the preheated non-woven fabric is embossed through the embossing device 2, the heating temperature of the embossing roller 21 is 135°C, and the heating temperature of the soft rubber roller 22 is 50°C;

[0038] (3), the embossed non-woven fabric is fluffed through the hot air blowing device 5, and the hot air temperature of the hot air blowing device 5 is 120°C.

[0039] (4) The embossed non-woven fabric is cooled by a cooling device, and then rolled.

Embodiment 3

[0041] The production process of 3D flexible embossed non-woven fabrics includes the following steps:

[0042] (1), non-woven fabric is preheated through preheating device 1, and the preheating temperature of preheating device 1 is 100 ℃;

[0043] (2), the preheated non-woven fabric is embossed through the embossing device 2, the heating temperature of the embossing roller 21 is 125°C, and the heating temperature of the soft rubber roller 22 is 80°C;

[0044] (3), the embossed non-woven fabric is fluffed through the hot air blowing device 5, and the hot air temperature of the hot air blowing device 5 is 95°C.

[0045] (4) The embossed non-woven fabric is cooled by a cooling device, and then rolled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com