A kind of preparation method of hydrophilic anti-ultraviolet fabric finishing agent

A fabric finishing agent and anti-ultraviolet technology, which is applied in fiber treatment, textiles and papermaking, and improved hand-feeling fibers. It can solve the problems of graphene oxide such as poor conductivity, poor washability, and non-hydrophilicity. Excellent overall performance, reasonable structure, and good washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

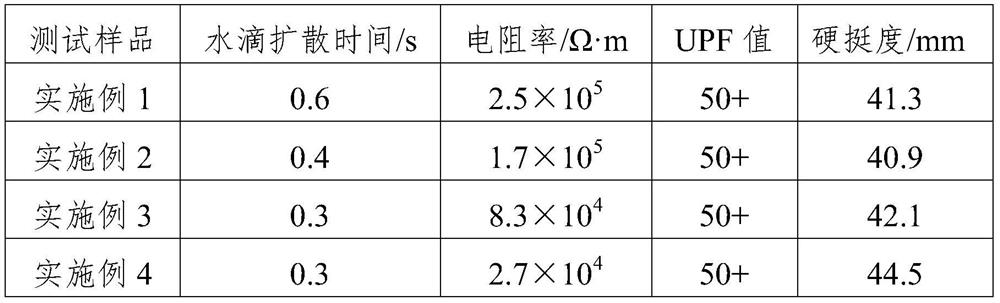

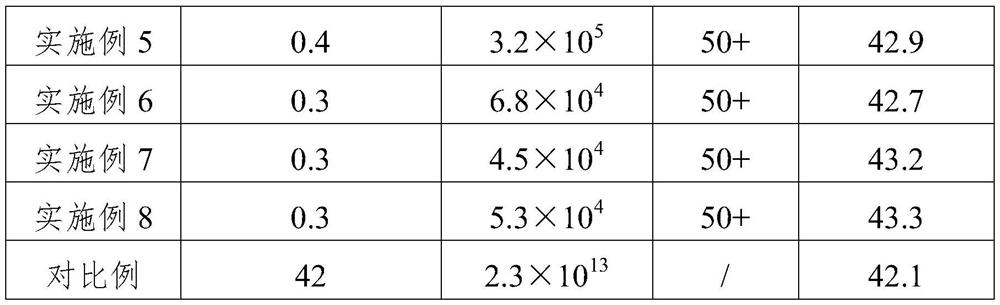

Examples

Embodiment 1

[0046] Add 1 part of graphene / POSS composite material 1 to 1000 parts of absolute ethanol, and ultrasonically disperse for 20 minutes to obtain fabric water-repellent finishing agent 1.

Embodiment 2

[0048] Add 5 parts of graphene / POSS composite material 2 into 1000 parts of absolute ethanol, and ultrasonically disperse for 20 minutes to obtain fabric water-repellent finishing agent 2.

Embodiment 3

[0050] Add 10 parts of graphene / POSS composite material 3 to 1000 parts of absolute ethanol, and ultrasonically disperse for 25 minutes to obtain fabric water-repellent finishing agent 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com