Temperature-resistant and compressive cable and production equipment and production technology thereof

A technology for production equipment and cables, which is applied in the field of temperature-resistant and pressure-resistant cables and their production equipment and production technology, which can solve problems such as limited temperature and pressure resistance, impact on service life, and easy skin damage, so as to increase pressure resistance. , prolong the service life and increase the effect of insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

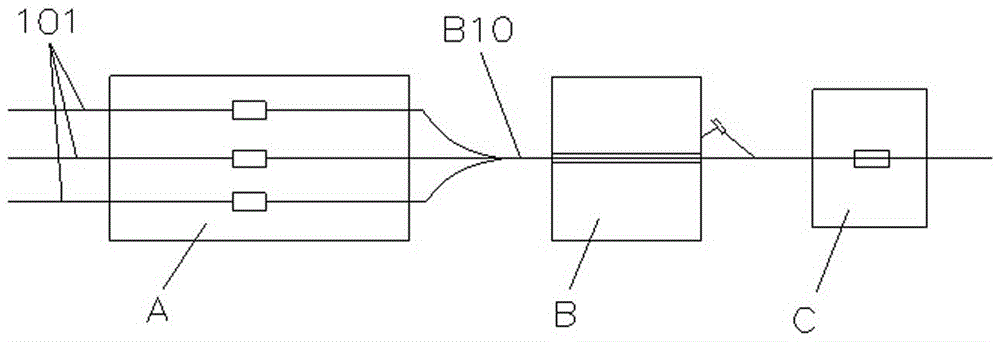

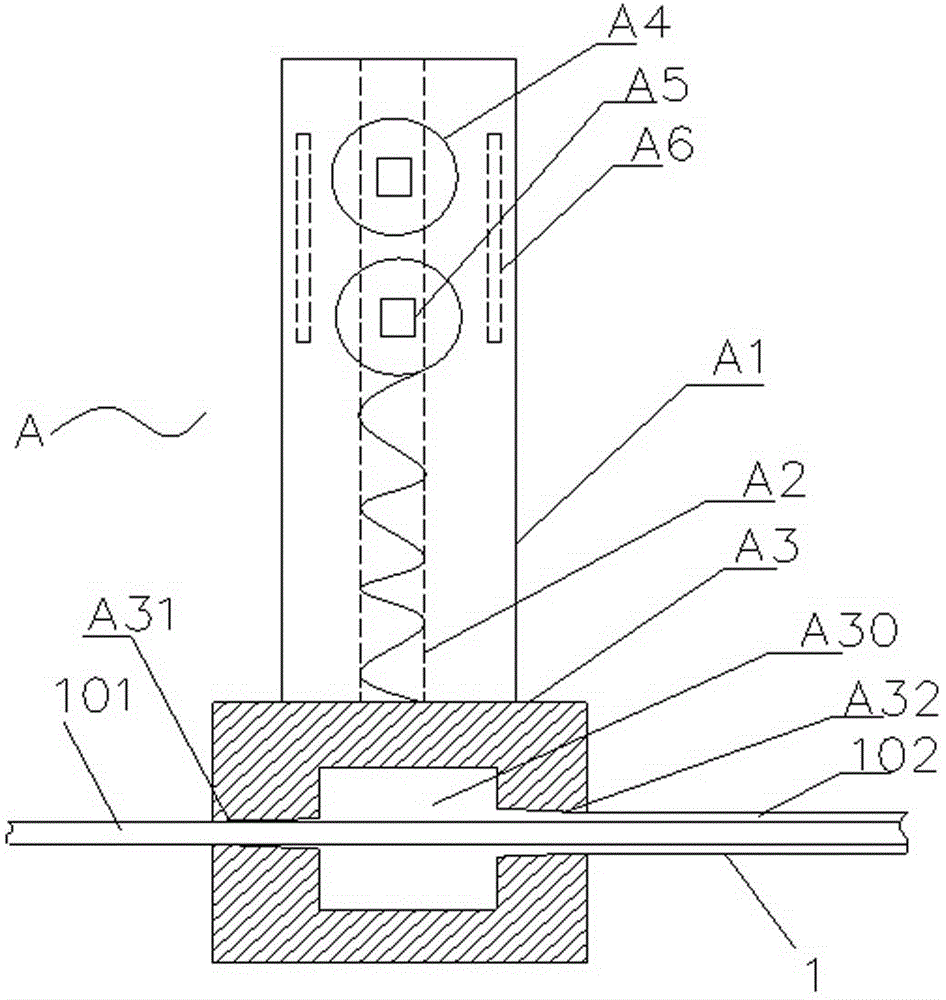

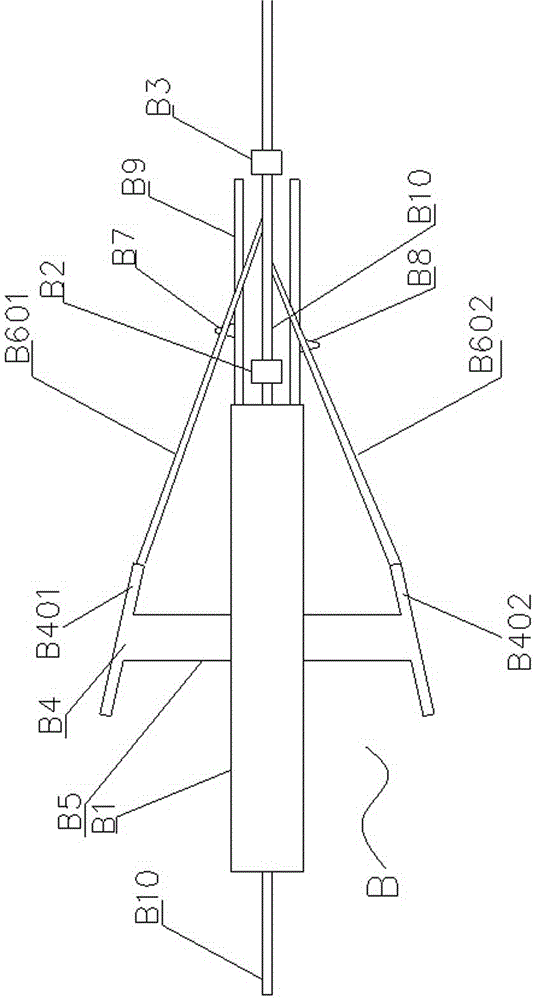

[0029] The temperature-resistant and pressure-resistant cable of the present invention includes three twisted core wires 1, a mica tape layer 2 wrapped around the three core wires, and a galvanized iron layer 3 wrapped outside the mica tape layer 2, and the periphery of the galvanized iron layer 3 is extruded There is a cable sheath 4 .

[0030] Further, for rational design, the core wire 1 includes a conductive metal inner core wire 101 and a plastic skin 102 .

[0031] Further, in order to design rationally and make the electrical performance of the cable better, a plurality of second core wires 5 are arranged on the peripheral side of the above three twisted core wires, and the wire diameter of the second core wires is three times that of the core wires. The layout of the multiple second core wires 5 makes the composition of the cable closer to a circle.

[0032] The temperature-resistant and pressure-resistant cable of the present invention increases its withstand voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com