Molding die of straight-tenon light wallboard and molding method thereof

A light-weight wallboard and forming mold technology, which is applied in the direction of molds, ceramic forming machines, mold separation devices, etc., can solve the problems of increasing the disassembly and assembly steps of the middle partition, high cost of forming molds, and easy leakage of materials, etc., to achieve The effect of omitting the process of disassembling and assembling the middle partition, simplifying the production process steps and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

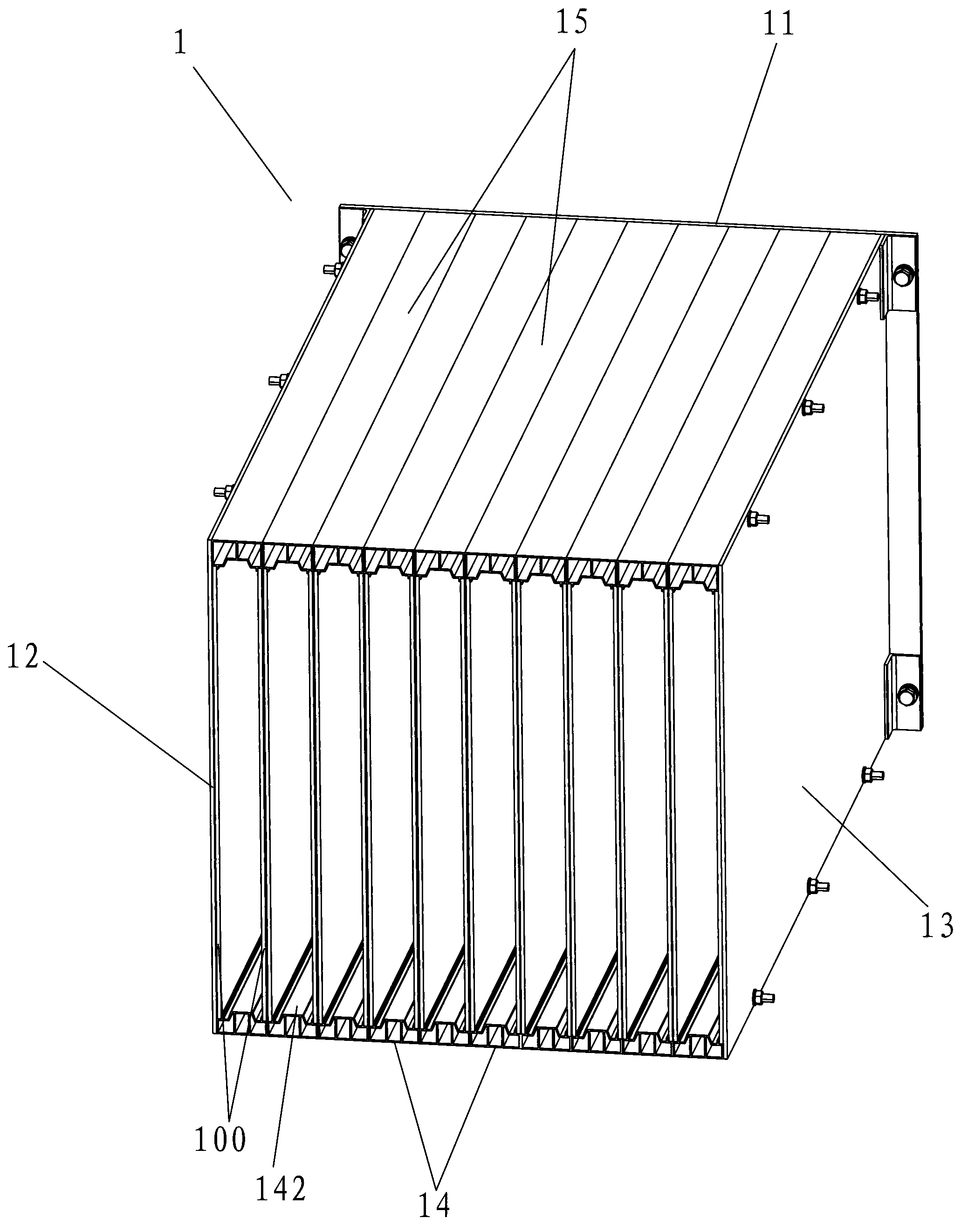

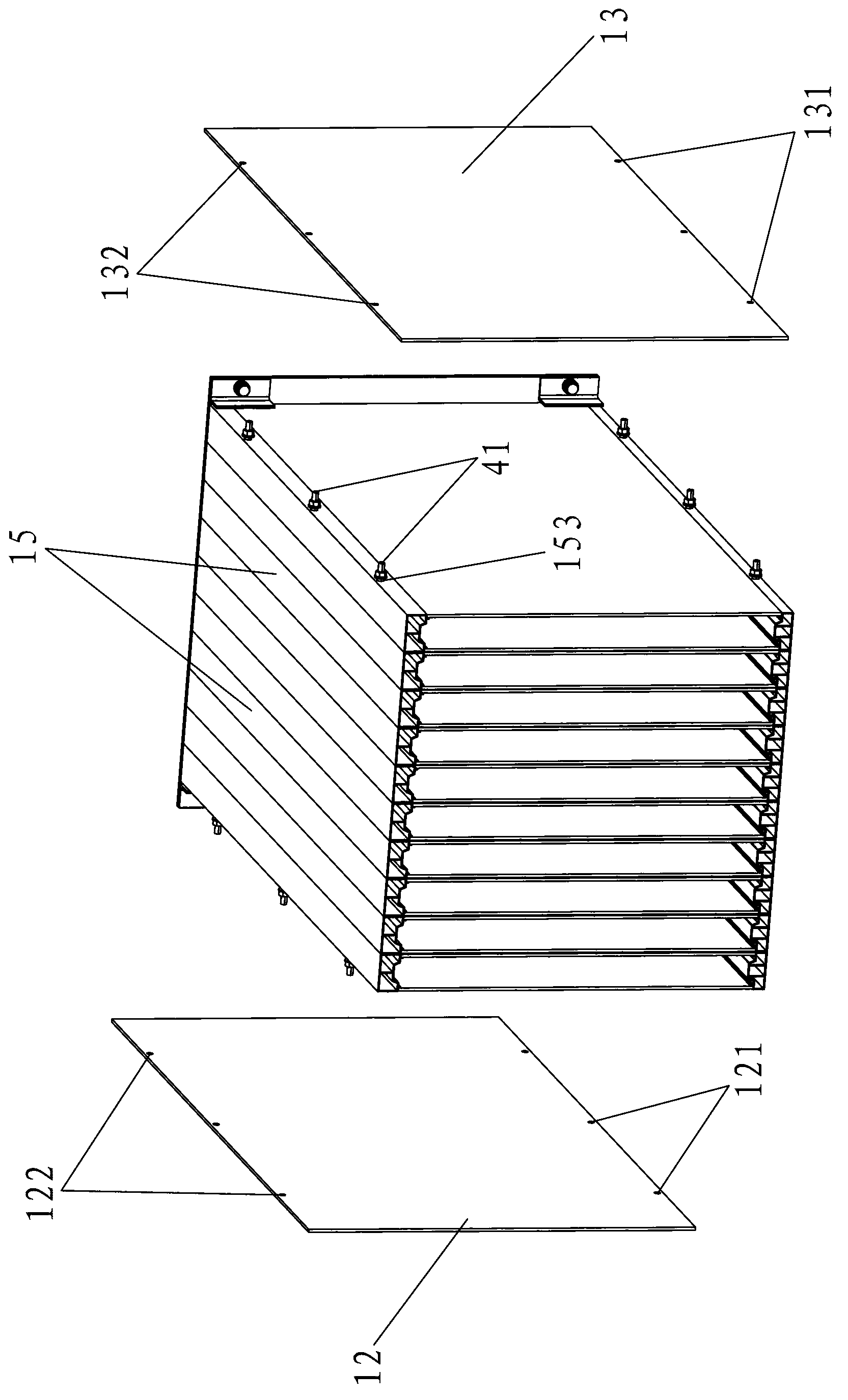

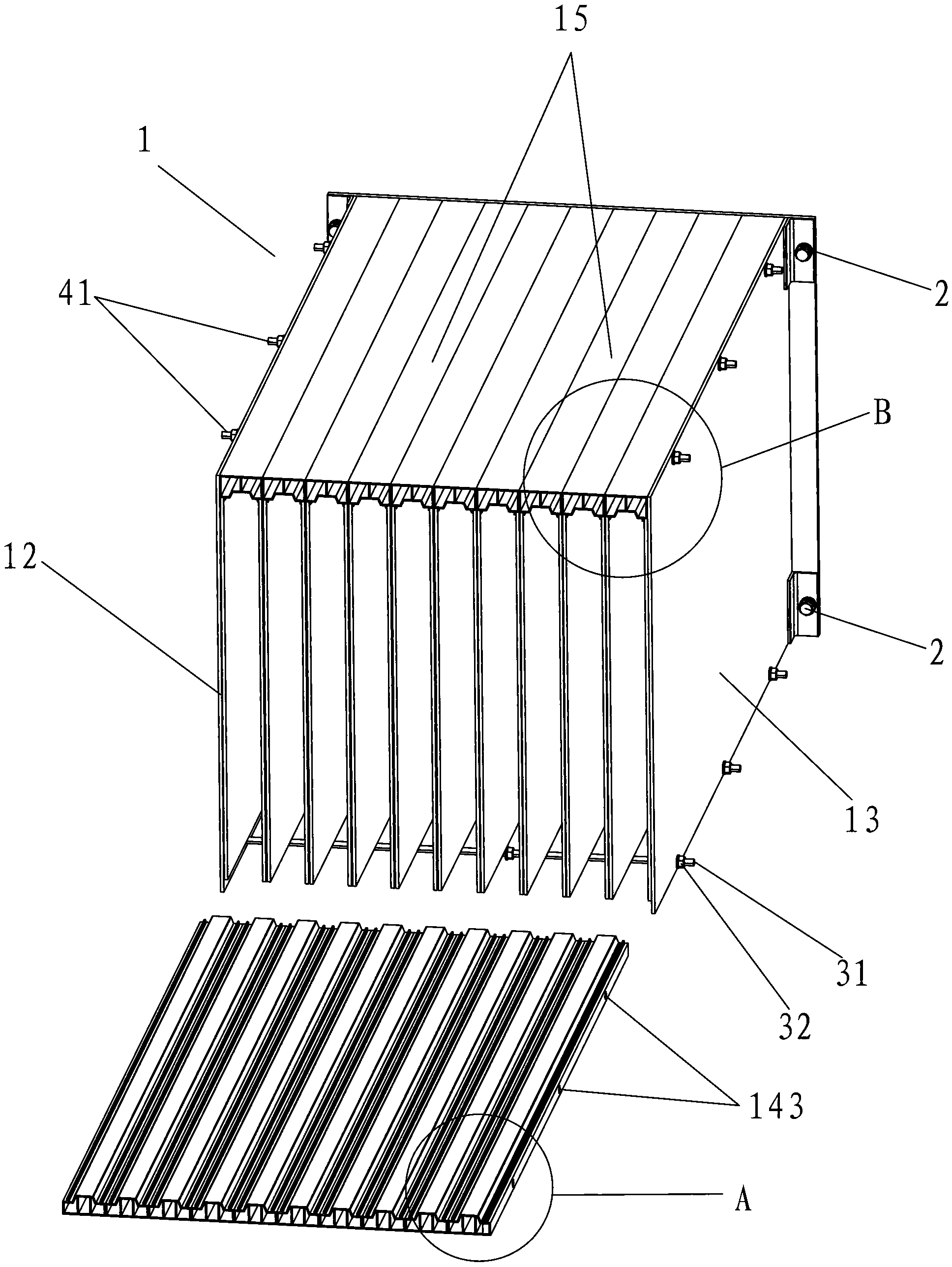

[0031] The molding die 1 of straight tenon lightweight wallboard of the present invention, as Figure 1-5As shown, it includes a lower base plate 11, a front side plate, a rear side plate, a left side plate 12 and a right side plate 13, and the lower ends of the left and right side plates 12, 13 are respectively locked on the lower base plate 11 by bolts 2. The side panels are assembled from several front strip-shaped aluminum alloy molding modules 14 that are closely erected side by side, and the rear side panels are assembled from several rear strip-shaped aluminum alloy molding modules 15 that are closely erected and arranged together. , the lower bottom plate, the front side plate, the rear side plate, the left side plate and the right side plate enclose a chamber whose upper end is open, and several wallbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com