Method for forming whole axle housing of automobile drive axle

A molding method and drive axle technology, applied to axles, wheels, furnace types, etc., can solve the problems of unreachable technical indicators of heavy vehicles, difficult control of casting quality, complicated manufacturing process, etc., to achieve improved comprehensive mechanical properties, easy operation, The effect of improving ultimate strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

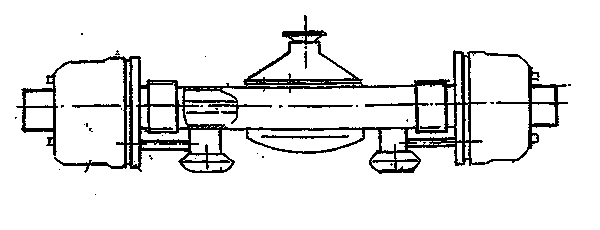

[0031] figure 1 Shown is a schematic structural diagram of a drive axle in the prior art.

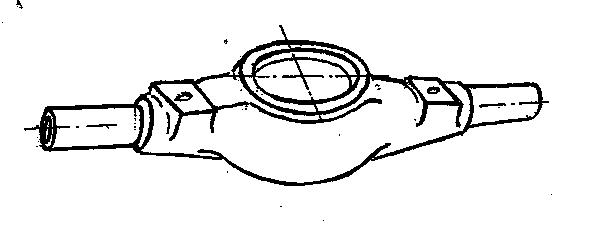

[0032] figure 2 Shown is a schematic diagram of the cast axle housing structure in the prior art.

[0033] image 3 Shown is a structural schematic diagram of a stamped and welded steel plate axle housing in the prior art.

[0034] Figure 4Shown is a schematic structural view of a steel pipe expansion welded axle head axle housing in the prior art.

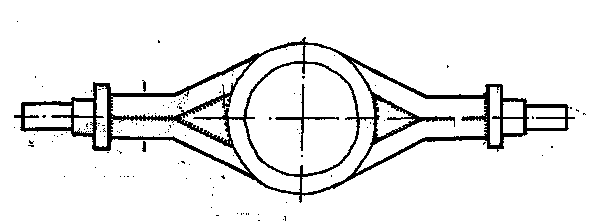

[0035] Figure 5 Shown is the schematic diagram of the overall axle housing of the automobile drive axle of the present invention.

[0036] Image 6 Shown is the shaft nose molding machine used in the molding method of the present invention for integral axle housing molding. There is a large-diameter spindle 4 in the spindle box 5. The spindle 4 is used to insert the steel pipe 3 to be processed. There are slides on the bed 6 at both ends of the spindle 5. rail, two hydraulic thrust boxes 1 and mold box 2 are installed on the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com