Tea extraction liquid, tea beverage, and preparation methods of tea extraction liquid and tea beverage

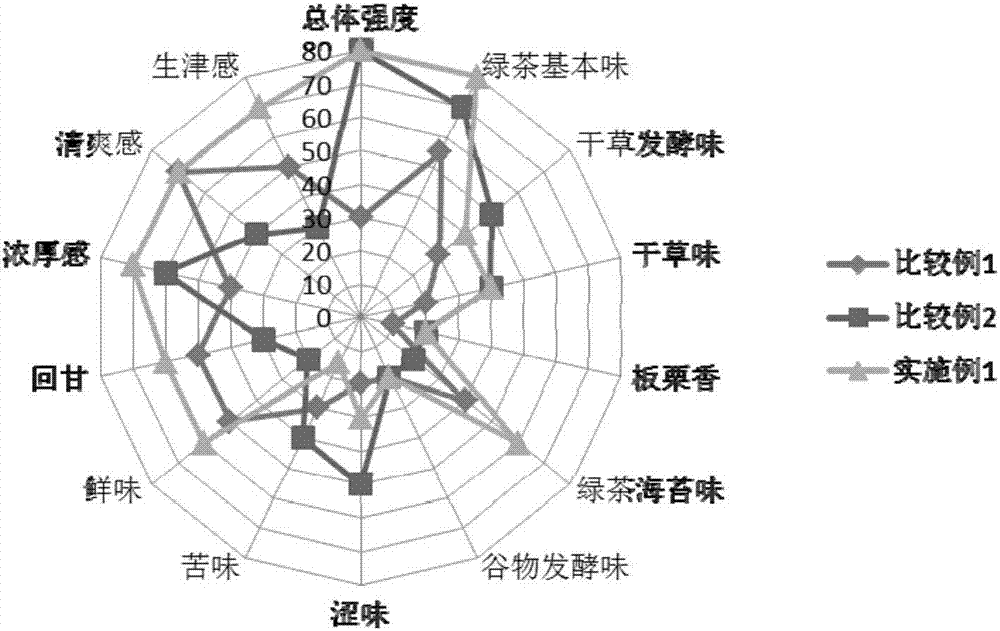

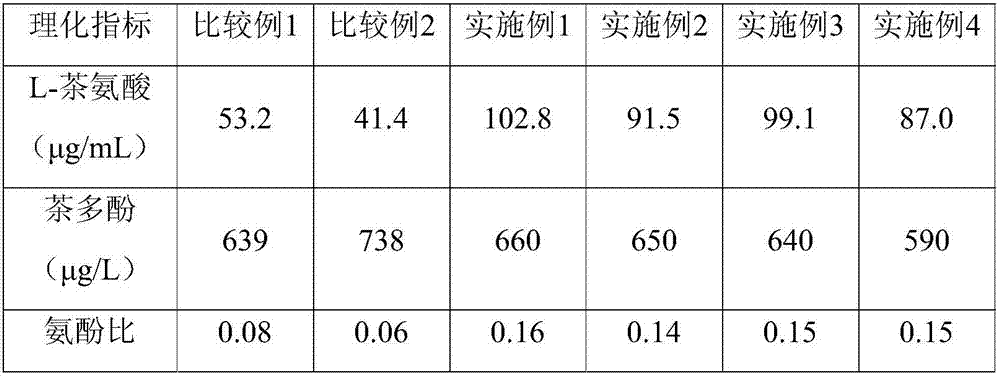

A technology for extracting liquid and tea beverage, which is applied in the field of food processing, can solve the problems such as insufficient aroma of tea leaves, insufficient fresh taste, heavy bitterness and astringency, etc., and achieves the effects of good aftertaste, high aroma and full tea feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of tea extract, the steps are as follows:

[0030] 1) Dual-temperature extraction: Divide the green tea leaves into the first part of tea leaves and the second part of tea leaves, the mass ratio of the first part of tea leaves and the second part of tea leaves is 1:1; add the first part of tea leaves into water for extraction, the extraction temperature is 40 °C, The extraction time was 6 minutes, the mass ratio of tea water extracted from the first part of tea leaves was 1:20, and the solid-liquid separation was carried out to obtain the first part of tea extract; The mass ratio of tea to water in the two-part tea extraction is 1:20, and the solid-liquid separation is carried out to obtain the second part of the tea extract;

[0031] 2) Mixing and clarification: the first part of the tea extract obtained in step 1) is mixed with the second part of the tea extract, and clarified to obtain the tea extract.

[0032] The preparation method of tea be...

Embodiment 2

[0036] The preparation method of tea extract, the steps are as follows:

[0037] 1) Dual-temperature extraction: Divide the green tea leaves into the first part of tea leaves and the second part of tea leaves, the mass ratio of the first part of tea leaves and the second part of tea leaves is 2:8; add the first part of tea leaves into water for extraction, the extraction temperature is 10°C, The extraction time is 10 minutes, the mass ratio of tea water extracted from the first part of tea leaves is 1:30, and the solid-liquid separation is carried out to obtain the first part of tea extract; The mass ratio of tea to water in the two-part tea extraction is 1:25, and the solid-liquid separation is carried out to obtain the second part of tea extract;

[0038] 2) Mixing and clarification: the first part of the tea extract obtained in step 1) is mixed with the second part of the tea extract, and clarified to obtain the tea extract.

[0039] The preparation method of tea beverage,...

Embodiment 3

[0043] The preparation method of tea extract, the steps are as follows:

[0044] 1) Dual-temperature extraction: Divide the green tea leaves into the first part of tea leaves and the second part of tea leaves, the mass ratio of the first part of tea leaves and the second part of tea leaves is 8:2; add the first part of tea leaves into water for extraction, the extraction temperature is 25 °C, The extraction time is 5 minutes, the mass ratio of tea water extracted from the first part of tea leaves is 1:25, and the solid-liquid separation is carried out to obtain the first part of tea extract; The mass ratio of tea to water in the two-part tea extraction is 1:30, and the solid-liquid separation is carried out to obtain the second part of the tea extract;

[0045] 2) Mixing and clarification: the first part of the tea extract obtained in step 1) is mixed with the second part of the tea extract, and clarified to obtain the tea extract.

[0046] The preparation method of tea bever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com