Patents

Literature

42results about How to "Soup is clear and bright" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

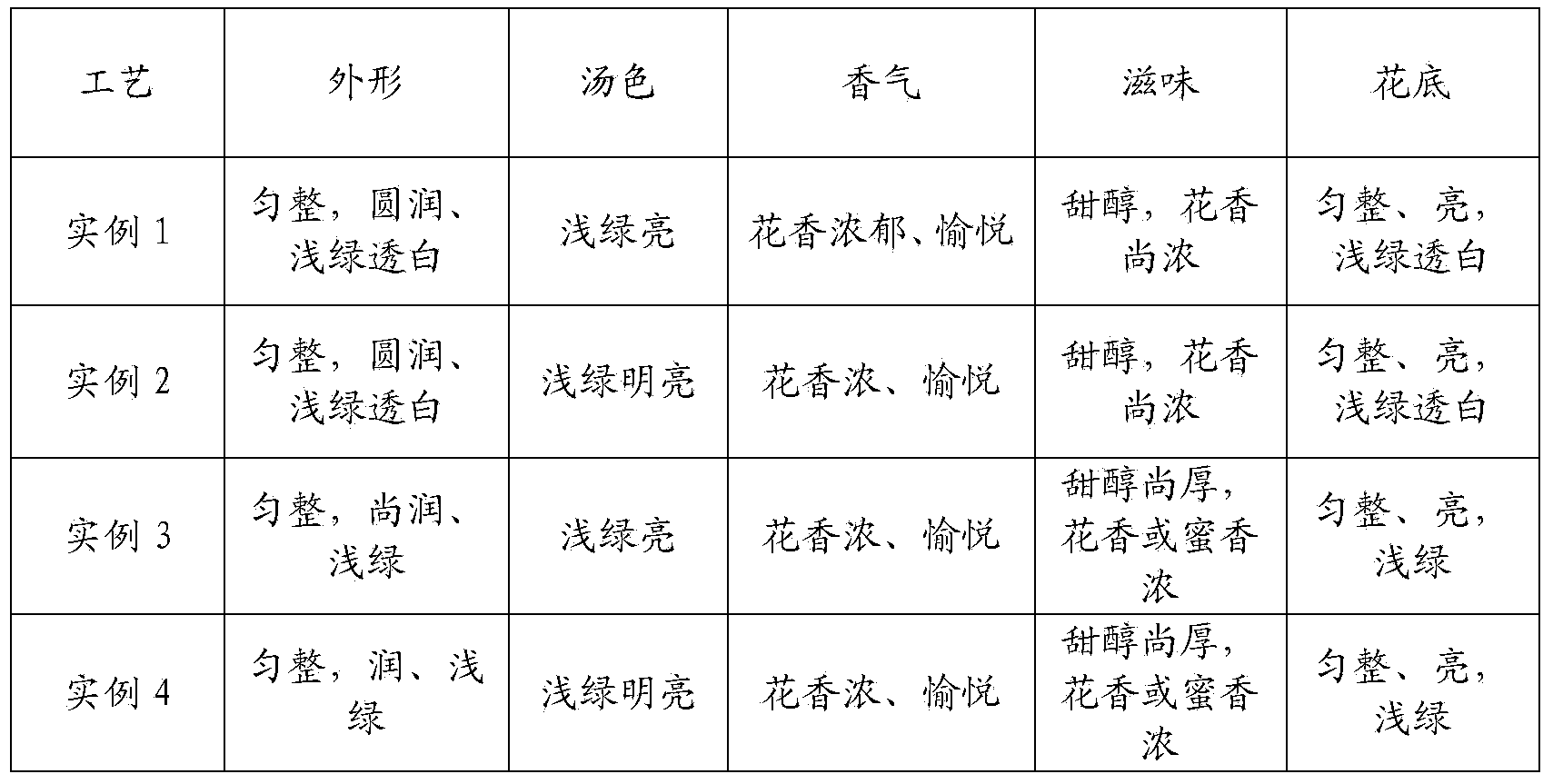

Preparation method of green tea of orchid odor type

The invention provides a method for preparing orchid fragrance green tea, which comprises the following steps in turn: firstly, picking tea buds, performing classification and sun withering on the tea buds, and fixing the tea buds at the temperature of between 150 and 170 DEG C after sun withering; secondly, laying open the fixed tea buds to be cooled or performing air-blasted cooling on the fixed tea buds, subsequently utilizing a microwave machine to dehydrate the tea buds, slightly rolling the tea buds, performing carding on the rolled tea buds at the temperature of between 120 and 140 DEG C, and primarily drying and reshaping the tea buds in a baking machine at the temperature of between 80 and 90 DEG C until 80 percent of the tea buds are dried; thirdly, laying the tea buds open to be cooled again; and fourthly, re-baking the tea buds in the baking machine at the temperature of between 80 and 90 DEG C until 90 percent of the tea buds are dried, laying open the tea buds to be cooled for the second time, extracting fragrance in a fragrance extracting machine for 1 hour at the temperature of between 75 and 85 DEG C, extracting fragrance for the second time after selection, and preparing finished products. The tea prepared by the process has fine, tall and graceful appearance, bloom green color and luster, exposed silver tips, fresh and delicate fragrance, dense and fresh flavor, clear and bright liquor color, young and tender infused leaves, and greenish-yellow and bright color, and the fact that the prepared green tea can reach the highest grade, namely orchid fragrance is the most important.

Owner:WUXI DONGTIANXIUZHU TEA +1

Processing method for tea flowers

The invention relates to a processing method for tea flowers. The processing method comprises the following steps: picking the tea flowers, withering, carrying out fixation, drying and packaging. According to the method, a microwave water removing machine is utilized for rapidly finish fixation in short time; meanwhile, in a fixation process, a lot of water molecules are escaped and evaporated from the tea flowers so as to realize the primary drying aim; the color, the flavor, the shape and the taste of the fresh tea flowers can keep unchanged to the greatest extent and effective substances are kept to the greatest extent; the high-aroma and the high-quality tea flowers are prepared.

Owner:GUANGXI GUILIN TEA RES INST

Fresh flower paste and preparation method thereof

ActiveCN102697027AHigh nutritional valueSoup is clear and brightFood preparationHigh-fructose corn syrupHigh fructose

The invention discloses fresh flower paste and a preparation method thereof and belongs to the technical field of edible paste. The fresh flower paste comprises high fructose corn syrups, fresh jasmine, white granulated sugar, jasmine juice, honey, edible gelatin, a flavoring agent and water. According to the fresh flower paste, the fresh jasmine is used as a raw material; by the method, high temperature sterilization is performed, the natural color can be kept, and the flavoring agents such as honey are added, so that the fresh flower paste is natural and faint in scent, intense in fragrance, clear and bright in liquor, strong and mellow in taste, and high in nutritional value, and is an ideal raw material when soaked independently for drinking or matched with other flowering tea.

Owner:杭州博多工贸有限公司

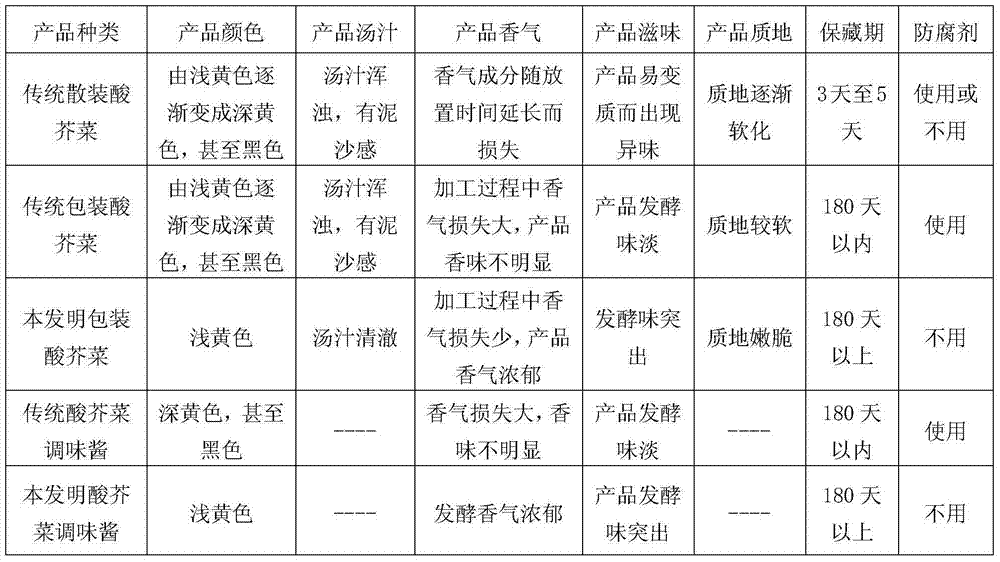

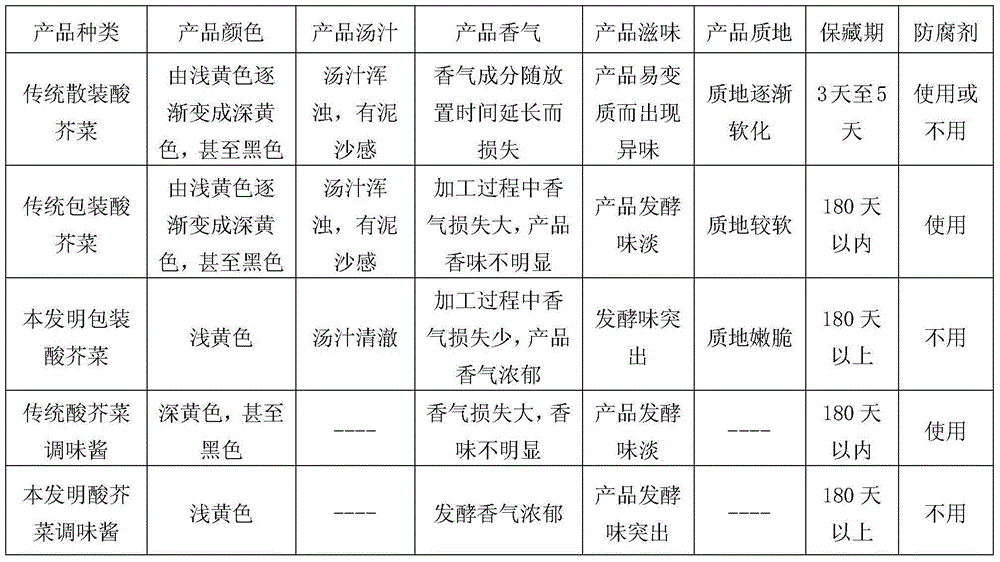

Acid mustard and processing method of acid mustard sauce

ActiveCN103783466ALight colorSoup is clear and brightClimate change adaptationFood preparationEthylene diamineAcetic acid

The invention relates to acid mustard and a processing method of acid mustard sauce. The acid mustard is prepared by cleaning an acid mustard semi-finished product which is primarily pickled and fermented by brine and clear water, and then sealing; taking out the cleaned acid mustard semi-finished product, evenly mixing fresh ginger into the acid mustard semi-finished product, adjusting the concentration of table salt, sealing, and pickling and fermenting for a second time; after that, cooling to low temperature, taking out the product and cutting; and mixing the cut material with clear water, feeding ethylene diamine tetraacetic acid disodium and citric acid, sealing, and sterilizing for a short time at the low temperature. The acid mustard sauce is prepared by cooling the acid mustard semi-finished product which is cleaned as well as pickled and fermented twice, cutting into small pieces, carrying out low-temperature superfine grinding and then sealing, and sterilizing for a short time at the low temperature. The acid mustard produced by the method is light yellow in color, strong in taste, rich in fragrance, clear in soup and long in storage period; the acid mustard sauce is fine and smooth in mouthfeel, strong in taste, rich in fragrance and long in storage period.

Owner:HUNAN DONGTING MINGZHU FOOD CO LTD

Preparation method of lycium ruthenicum murr tea

The invention relates to a preparation method of boxthorn leaf tea, and particularly relates to a preparation method of lycium ruthenicum murr tea. The preparation method is characterized by comprising the following steps: as fresh lycium ruthenicum murr is taken as a raw material, cleaning the picked fresh tender leaves at the middle mature period; withering, de-enzyming, rolling, molding, drying and packaging. The lycium ruthenicum murr tea is unique in raw material, and good in taste, and has the health-care effects of resisting oxidation, reducing blood sugar, reducing blood fat and the like.

Owner:NINGXIA DINGLI AGRI DEV

Method for processing floral-type Taihu bamboo tea

InactiveCN101755934APrevent volatilizationIncrease floral fragrancePre-extraction tea treatmentEnzymeChemistry

The invention relates to a method for processing floral-type Taihu bamboo tea. The method can improve aroma of the floral-type Taihu bamboo tea and maintain the aroma for a long time, thereby improving the quality of the finished Taihu bamboo tea. The invention comprises the following processing steps: grading of fresh leaves, spreading and cooling, enzymes-passivating, initial drying, rolling, carding, re-drying, spread-cooling deterioration and adequate fire drying. The invention is characterized in that: when the fresh leaves are spread and cooled, the indoor temperature is maintained at 14-22 DEG C; the humidity is 70%-90%; the thickness of spreading leaves is 0.5cm-1.5cm; the spreading and cooling time is 4-8 hours; and the weight loss rate of the fresh leaves is 15%-25%, wherein the percent content in each step is mass percent;.

Owner:无锡市茶叶品种研究所有限公司

Preparation method of instant chrysanthemum powder

ActiveCN102845803AWide variety of sourcesEfficient use ofPre-extraction tea treatmentPectinaseUltrafiltration

The invention discloses a preparation method of instant chrysanthemum powder. The method comprises the steps of: chrysanthemum straw picking, chopping, enzyme-deactivating, leaching, enzyme extracting, juicing, oxidation resisting, pectinase decomposing, starch standing, multiplex filtering, reverse osmosis ultrafiltration, vacuum concentrating, vacuum spray drying, and vacuum packaging. Compared with prior arts, the instant chrysanthemum powder prepared with the method provided by the invention is yellowish brown powder. The instant chrysanthemum powder has mellow and refreshing taste, a unique chrysanthemum fragrance, and a total flavonoid content reaching 2-3%.

Owner:黄山光明茶业有限公司

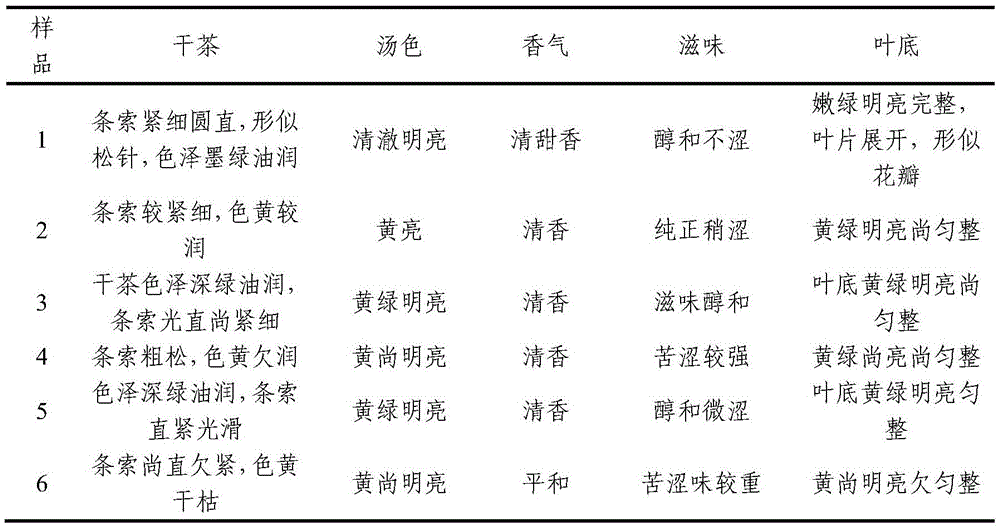

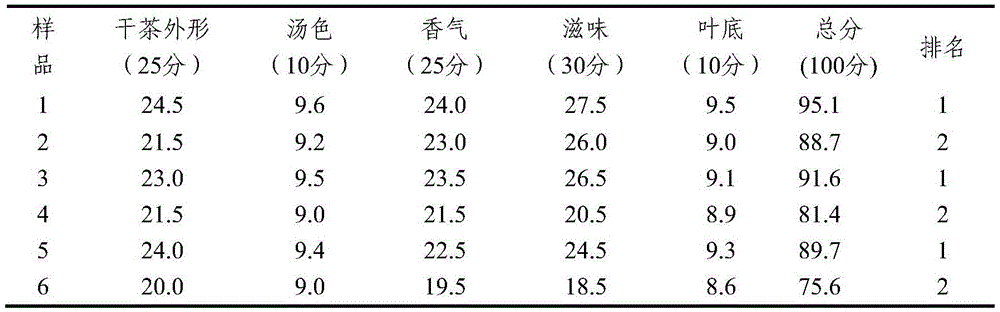

Pine needle shaped steam tea pomegranate green tea and preparation method thereof

The invention provides a preparation method of pine needle shaped steam tea pomegranate green tea. The method mainly comprises the steps of pomegranate leaf withering, steam fixation, flabellation, drying performed in a shaking mode, twisting and drying. The temperature and humidity control withering mode, the steam fixation mode, and the primary, intermediate and shaping three-time heating twisting mode are adopted, compared with a traditional processing technology, the defects that due to unreasonable spreading, pomegranate leaf tea is bitter in taste, heavy in green grass odour, the penetrating power of dry-heat air is not strong in the process of dry-heat fixation, enzyme activity passivation is not thorough, the fixation effect is not uniform, burnt edges and blisters or red stalks and leaves or the like are likely to appear are overcome, and the defect that tea appearance is thick and strong or the short and broken rate is high due to a traditional rolling mode is overcome, so that the product quality characteristics are greatly improved, and the obtained green tea has the advantages that the dry tea is black green and glossy in color, the appearance is tight, thin, round and straight, the tea is similar to pine needles in shape, the liquor color is limpid and bright, the leaf bottom is light green, bright and uniform, the fragrance is clean and sweet or clean aroma or flowery fragrant, and the taste is mellow and not astringent.

Owner:刘建军

Processing method of selenium-copper-rich green tea

InactiveCN106260201AEmerald green colorLong-lasting fragranceBio-organic fraction processingPre-extraction tea treatmentAdditive ingredientEmerald

The invention discloses a processing method of selenium-copper-rich green tea, and belongs to the technical field of tea processing. The processing method of selenium-copper-rich green tea provided by the invention has the advantages that according to the growth characteristics of a tea tree, an organic selenium copper nutrient solution is fully supplemented in the growth period of the tea tree; after being harvested, tea leaves are subjected to a series of simple processing such as spread drying, water removing and fumigating, so that after the tea leaves are brewed; tea buds are upright; the effect that as one falls, another rises is achieved; the color and luster are emerald green; the fragrance is aromatic and durable; the soup color is clear and bright; the taste is fresh, cool and mellow; the leave bottom is tender green and complete; the ornamental value is realized; in addition, the organic selenium copper content is obvious; no any injury is caused on the human body; meanwhile, the effective ingredients of tea polyphenol, amino acid and theine in the tea leaves are remained to the great degree; the tea leaf quality is improved, so that the commodity property of the tea leaves is greatly improved.

Owner:文县科学技术局

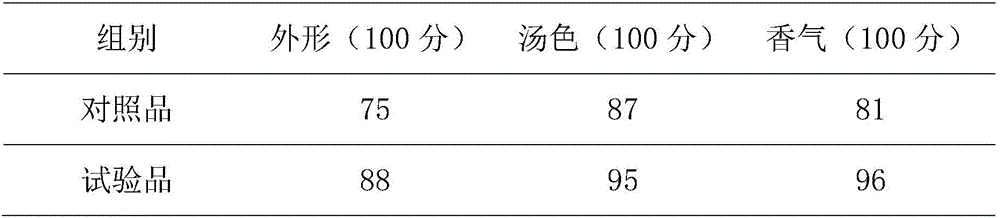

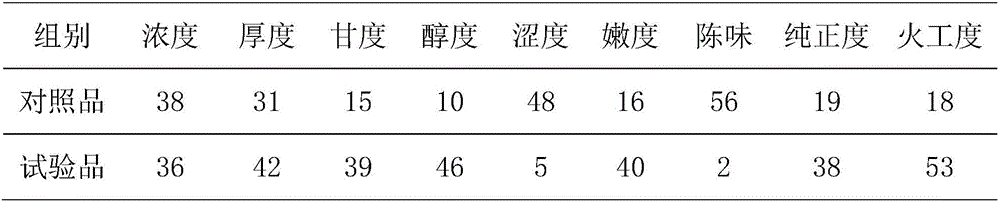

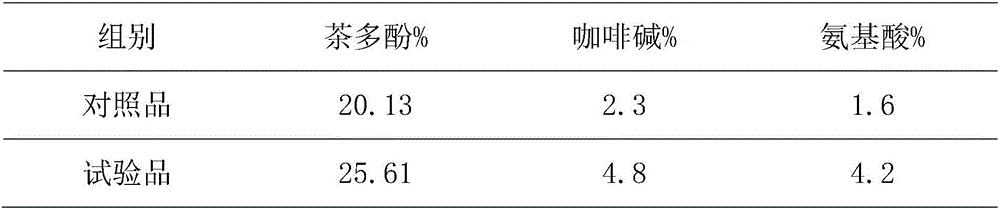

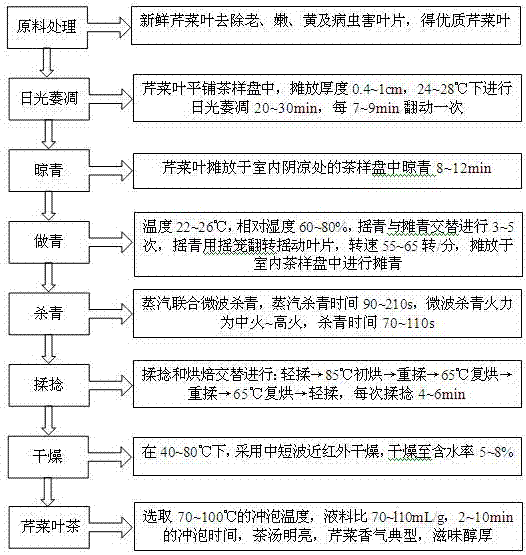

Method of creation of celery leaf tea

The invention relates to the technical field of tea processing, in particular relates to a method of creation of celery leaf tea. The status quo of the use of celery leaf as technology waste only is altered, and a new approach is provided for processing and utilization and value-added efficiency of celery leaves. By the method of creation of celery leaf tea, the celery leaves are subject to the process of withering, raw drying, and greening, the method of steam combined with microwave blanching is adopted, after rolling, tea leaf desiccation is conducted using medium and short wave infrared, by the subjecting to suitable brewing method, celery leaf semi-fermented tea is obtained. The produced celery leaf tea product is tight and strong, black in color, strong in aroma, light in brewing liquid color, fresh and high in taste, and has the health benefits of depressurization, lipid-lowering and anti-oxidation and the like.

Owner:NORTHWEST A & F UNIV

Method for processing organic fragrant tea

InactiveCN102370013AEmerald green colorSoup is clear and brightPre-extraction tea treatmentChemistryWinnowing

The invention relates to a method for processing tea, in particular to a method for processing organic fragrant tea. The method for processing the organic fragrant tea comprises the processing steps of selecting materials, slightly withering, removing green, cooling, kneading and twisting, drying, winnowing and the like. In the method, processing machines are adopted in the process of processing the tea, so a flow line is formed integrally and yield is increased. The tea processed according to the steps has high quality, durable fragrance, faint fragrance slightly with orchid fragrance, strip-shaped, curled and attractive appearance, jade green color, flowers at the bottom of the tea, clear and bright soup color, and fresh and mellow taste.

Owner:浙江银奥茶业发展有限公司

Production method of fig-leaf healthcare tea

The invention relates to healthcare tea, in particular to a production method of fig-leaf healthcare tea. The production method includes: picking fresh fig leaves, soaking the fig leaves into mixing liquid containing Na<+> with the concentration being 8.2mg / L, K<+> with the concentration being 6.4mg / L and Fe<2+> with the concentration being 0.23mg / L, washing the soaked fig leaves with clean water, drying water on the surfaces of the fig leaves, stir-frying under 180-185 DEG C, flatly spreading the stir-fried fig leaves, rolling with a roller, and drying the rolled fig leaves under 50-55 DEG C until the moisture of the fig leaves is lower than 15% to obtain the fig-leaf healthcare tea. The production method has the advantages that the content of psoralen and furoeoumarin type photosensitive substances in the fig leaves can be lowered evidently, the mixing liquid also has a color protecting and green keeping effect, the obtained fig-leaf healthcare tea is dark green and flat and straight in appearance, and the tea liquor of the brewed fig-leaf healthcare tea is light green, clear and bright and mellow and sweet in taste.

Owner:安徽省怡果生态科技有限公司

Preparation method of Xiangyuan fog bud tea

The invention discloses a preparation method of Xiangyuan fog bud tea. The Xiangyuan fog bud tea serves as a raw material and is sequentially subjected to fresh leaf classification, tedding, hot air water removing, twisting of tea leaves to form strips, tea strip arranging and drying. Tea leaf moisture is controlled through tedding, bright and uniform color of the tea leaves obtained after water removing is guaranteed, and the taste of the tea leaves is improved. The tea leaves are preliminarily in a good form through control over twisting operation, and the tea leaves have a graceful form after tea strip arrangement. Most of the prepared tea leaves are in the form that two leaves exist on one bud, and the tea leaves are tippy and featured by green bloom, heavy body and rich fragrance. After the tea is brewed, the liquid color is yellow green, and the tea is clear, bright, clear and refreshed in chestnut flavor, sweet and mellow and durable.

Owner:ZHENAN SHENGHUA TEA DEV CO LTD

Production method of fragrant jasmine tea

InactiveCN106615366ASlim shapeFresh and elegant aromaPre-extraction tea treatmentTea flavoringGreen teaEpigallo-catechin gallate

The invention provides a production method of fragrant jasmine tea. The production method sequentially includes: picking green tea leaves, grading, withering, and performing enzyme deactivation on the withered green tea leaves at 150-170 DEG C; spreading the enzyme-deactivated green tea leaves for cooling or performing blast cooling on the enzyme-deactivated green tea leaves, using a microwave machine to dewater the green tea leaves, gently rolling, performing strip tidying on the rolled green tea leaves at 120-140 DEG C, preliminarily drying and shaping the green tea leaves in a drying machine at 80-90 DEG C until the green tea leaves are 80% dry; primarily spreading for cooling; drying the green tea leaves again in the drying machine at 80-90 DEG C until the green tea leaves are 90% dry, secondarily spreading for cooling, performing fragrance increasing in a fragrance increasing machine at 75-85 DEG C for 1 hour, selecting, and performing secondary fragrance increasing to obtain the fragrant jasmine tea. The production method has the advantages that the fragrant jasmine tea produced by the method is slim, tender and straight in appearance, green and moist in color, evident in silver villus, fresh and elegant in fragrance, mellow and fresh in taste, clear and bright in tea liquor, tender in leaf bottom, green, yellow and bright in color, and fragrant.

Owner:雅安市雨城区晏场鹿井茶厂

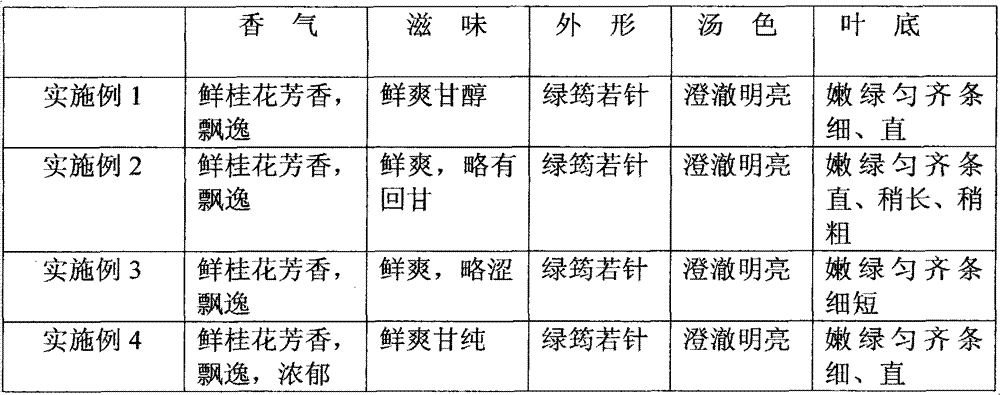

Treating method and product of organic osmanthus green tea

InactiveCN101946841BPromote absorptionDeep absorptionPre-extraction tea treatmentFlavorProduct characteristics

The invention discloses a treating method of an organic osmanthus green tea. The method comprises the following steps: selecting green tea raw material and fresh osmanthus, preparing, pretreating, scenting under the negative pressure and the sealing condition, parching to raise aroma, drying at a low temperature, and performing refinement, classification and other working procedures. The organic osmanthus green tea is suitable for industrialized production; and the technological conditions are easy to control, the product quality is stable and the product consistency of different batches is good. The invention also provides a product prepared by the above method. The organic osmanthus green tea of the invention has the product characteristics of green color, needle shape, bright and clean liquor color, attractive osmanthus incense, fresh and mellow flavor and vivid green and uniform bottom of leaves; and the original incense of green tea and the intense and elegant aroma of osmanthus are completely maintained, and the quality of the product achieves the standards of organic products.

Owner:义乌凌川科技有限公司

Honey snow pear puree and production method thereof

The invention relates to a honey snow pear puree and a production method thereof and belongs to the food processing technology field. The composition of the honey snow-pear puree comprises raw materials of fructose, diced snow pear, water, honey, glycine, edible salt, calcium chloride, sodium pyrosulfite, vitamin C, citric acid, carragheenan, xanthan gum, potassium sorbate, food flavour and whitesugar. The frozen diced snow pear is taken as a raw material of the honey snow pear puree; frozen sugaring is carried out by using the fructose; fine honey is added; nutrient loss is avoided to a great degree, and nutrition diversification is ensured. According to the invention, the prepared honey snow pear puree is natural and has gentle flowery flavour and outstanding aroma; the soup color is clear and bright; the taste is rich and mellow; the prepared honey snow pear puree not only can be taken as an ideal raw material for making tea individually, but also for making tea with other scentedteas; tea made from the prepared honey snow pear puree not only has delicate fragrance of snow pears, but also has functions of lung moistening and thirst quenching.

Owner:杭州博多工贸有限公司

Preparation method of silver needle pekoe

The invention discloses a preparation method of a silver needle pekoe, and belongs to the technical field of tea preparation. The preparation method comprises steps of bud picking, withering, baking, sieving, and vanning. The withering is performed by machines, the human labor is saved; in the baking step, tea leaves are heated and baked in a vacuum machine, intact tea leaves can be preserved, the leaf tips become up-curled and are not broken, and the pekoe has a good taste. Pekoe (5 grams) is brewed in 150 mL of hot water (80 DEG C) to observe the shape and color of the pekoe; the tea leaves are thick and tender, the color is white and bright, the leaf surface has a grey green color, the leaves are flat and spread, the leaf tips are up-curled and intact, the fragrance is rich, the taste is fresh and sweet, the tea soup gives off light jujube aroma, and the apricot yellow color of the tea soup is clear and bright.

Owner:SUZHOU LI LIANGJI HEALTH IND LTD

Preparation method of Qifo tribute tea cake

PendingCN110679674AReduce caffeineImprove palatabilityPre-extraction tea treatmentTea alkaloid content reductionCaffeineProcess engineering

The invention relates to the technical field of tea processing, in particular to a preparation method of a Qifu tribute tea cake, which comprises the following steps: step 1, picking fresh leaves; step 2, spreading and airing the fresh leaves; 3, washing the material with warm water; step 4, performing steam fixation; step 5, performing rolling; step 6, performing washing; step 7, performing baking and frying at high temperature; step 8, performing pressing and shaping; step 9, performing drying; and step 10, performing packaging. The summer tea is used as a raw material; meanwhile, a part ofoverflowing caffeine and polyphenol substances are removed through washing and soaking in hot water at 30-35 DEG C for 29-31 minutes, so that the caffeine content of the fresh tea leaves is reduced, and the taste of the tea leaves is closer to the taste of spring tea through steam fixation, baking and stir-frying and caffeine sublimation in the environment of 120 DEG C, so that the soup color becomes clearer and brighter, and finally, the pressed cake is shaped, so that the storage is facilitated, and the shelf life is prolonged.

Owner:青川县嘉发茶业有限公司

Processing method of macadimia nut leaf teabag

The invention discloses a processing method of macadimia nut leaf tea bags, and the method comprises the following steps: picking of fresh leaves: picking tender macadimia nut leaves and tender cyclocarya paliurus leaves for later use; selecting: selecting one-bud three-leaf tender leaves or tender leaves; spreading: spreading the selected tender leaves on a clean vessel, and placing the leaves at room temperature for 2-6 hours; microwave fixation: heating the leaves in a household microwave oven for 3-5 minutes; performing rolling: performing fixation on the macadamia nut leaves, performing spreading for cooling, performing manual rolling for 10-30 minutes, performing fixation on the cyclocarya paliurus tender leaves, and manually rolling the leaves for 10-30 minutes while the cyclocarya paliurus tender leaves; drying: adopting a hot air oven for drying, firstly drying the leaves at 50 DEG C for 1 hour, spreading the leaves for cooling, and then drying the leaves at 80 DEG C for 30 minutes; crushing: adopting a traditional Chinese medicine crusher to respectively crush and sieve macadimia nut leaves and cyclocarya paliurus leaves, and selecting 16-40-mesh particles for later use; and compounding: compounding the macadamia leaf particles and the cyclocarya paliurus leaf particles according to the ratio of (5: 1)-(1: 5). Compared with the prior art, the preparation method has the advantages of simple process, easiness in operation, convenience in preparation and good sweet aftertaste.

Owner:广东生态工程职业学院

Production process flow of single-bud Queshe tea

InactiveCN108552334AThe production process steps are simpleQuality improvementPre-extraction tea treatmentWater vaporDew

The invention provides a production process flow of single-bud Queshe tea. The production process flow comprises the following steps: firstly, picking tea leaves by manual work, and during picking, selecting one buds with one leaves with no mechanical damage, good evenness and good cleanliness rather than picking leaves with rain, leaves with dew, red or purple buds with leaves and buds with leaves with disease and pest; then placing the picked tea leaves on an airing frame, and performing airing to reduce the water content of the tea leaves to 68%-70%; placing the withered tea leaves in a steamer, and specifically, heating water vapor in the steamer to a saturated state before placing the tea leaves into the steamer; and maintaining the inside of the steamer at corresponding pressure, thereby performing fixation and softening on the tea leaves. The production process flow of the single-bud Queshe tea has simple steps and enables the tea quality to be better by selecting the mode of picking one buds with one leaves; the processed tea leaves are flat, straight and smooth in shape and jade green in color and luster; and the brewed tea liquor has mellow fragrance, clear and bright color, mellow, fresh and refreshing taste, lasting aftertaste and jade green, fresh and bright tea dregs.

Owner:黎平县侗乡永晟茶业有限责任公司

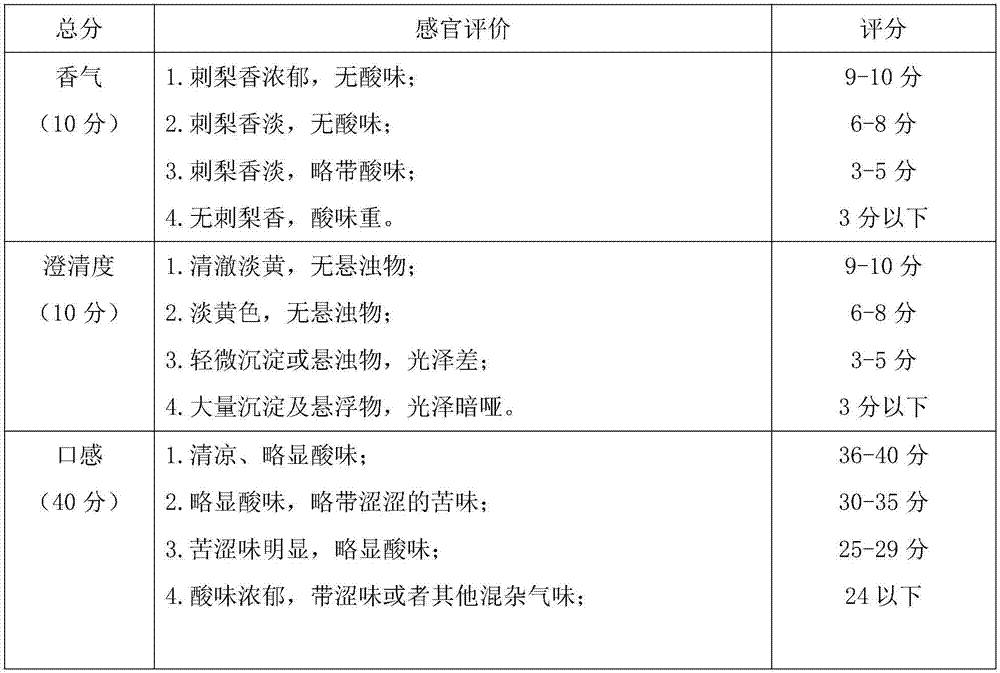

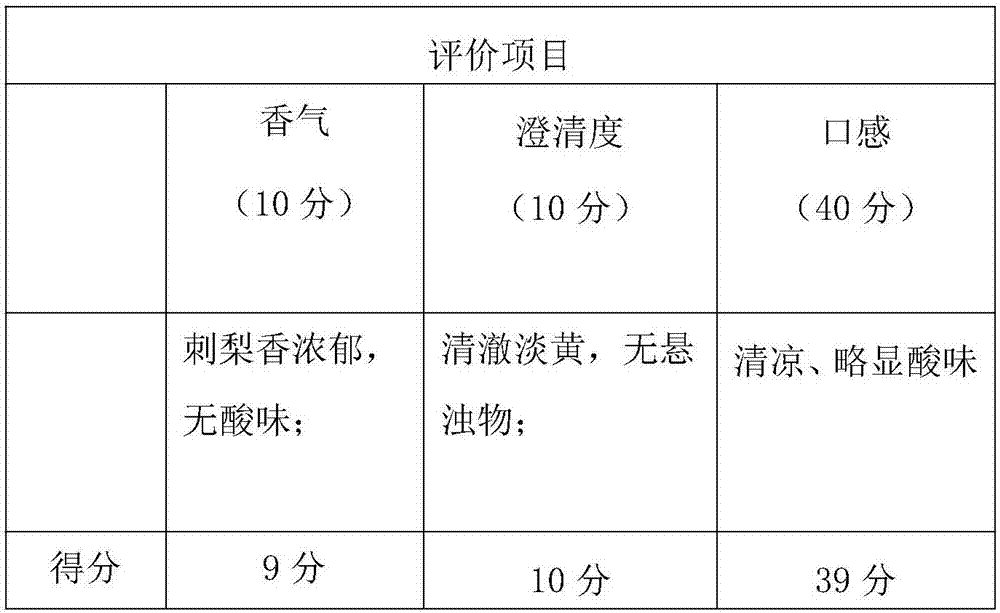

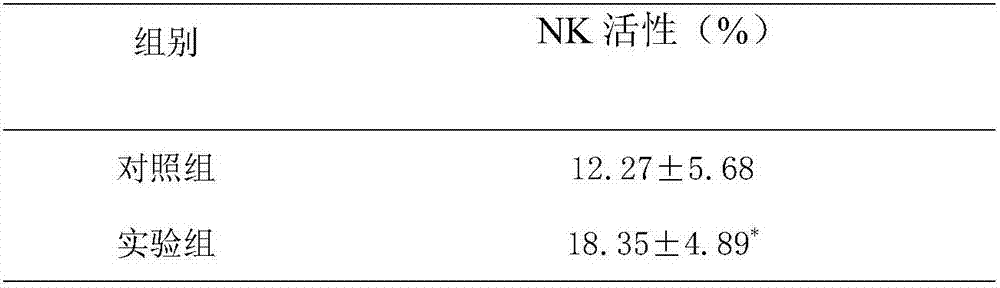

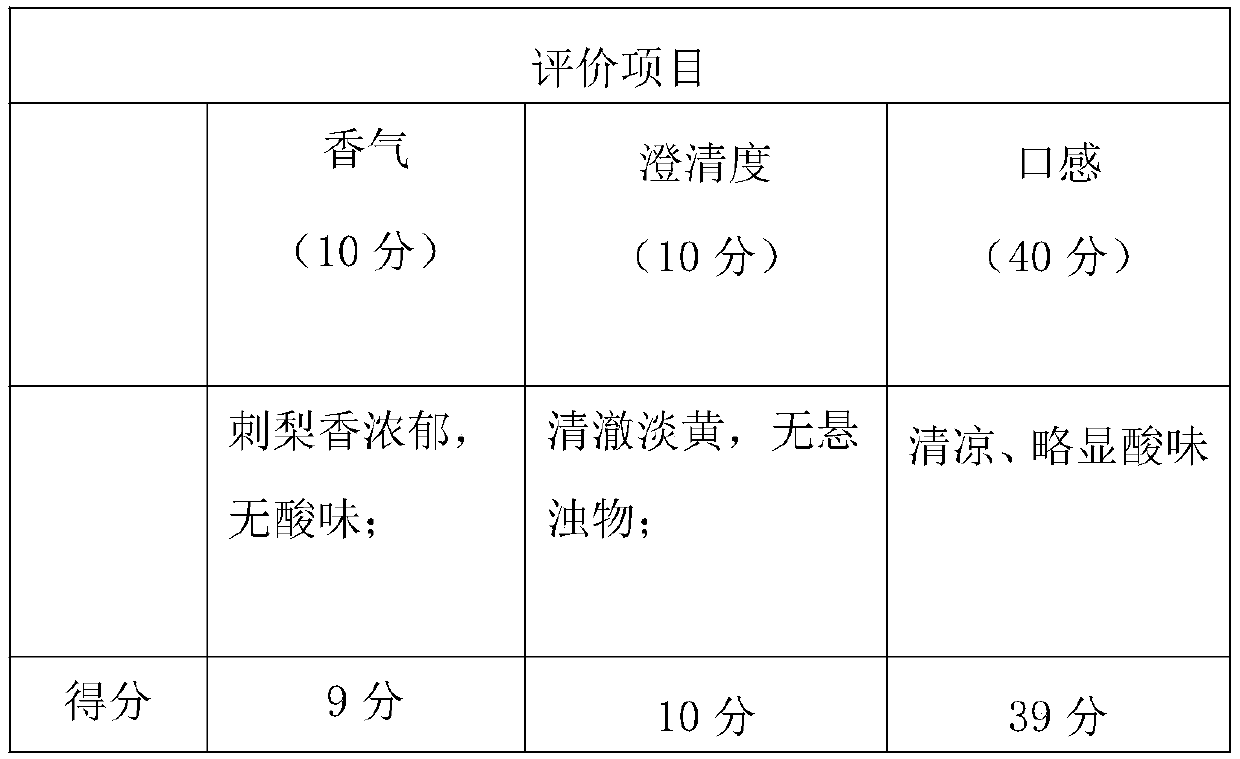

Health-care roxburgh rose beverage and preparation method thereof

ActiveCN107348267AQuality improvementSoup is clear and brightYeast food ingredientsFood ingredient as taste affecting agentYeastAdditive ingredient

The invention provides a health-care roxburgh rose beverage and a preparation method thereof. The health-care roxburgh rose beverage is prepared from roxburgh roses, dandelion, sweet osmanthus, hawthorn, glutinous rice, bran, sodium carbonate of which the concentration is 0.6%, yeast, tannase, citric acid and purified water. The health-care roxburgh rose beverage has good quality and bright and clear liquor color, is not easy to oxidize or brown, contains balanced nutritional ingredients, has good taste, is free of astringency, and also has the effects of enhancing physique and improving body immunity.

Owner:贵州恒力源天然生物科技有限公司

Production process of Queshe tea

InactiveCN111194792AAroma is mellowSoup is clear and brightPre-extraction tea treatmentGreen teasEngineering

The invention discloses a production process of Queshe tea, which is characterized by comprising the following steps: a, picking: picking tender green tea tips before and after Qingming; b, performingfixation: putting the picked fresh terminal bud tea leaves into a roller continuous fixation machine, performing fixation for the first time, and controlling the temperature of the inner wall of a roller of the roller continuous fixation machine to be 130 DEG C; c, performing cooling: cooling the tea leaves subjected to fixation at the temperature of 15-20 DEG C; d, pressing into strips: puttingthe tea leaves subjected to fixation and cooling into a furnace fixation roasting machine for carding, wherein the air temperature in the machine is 40-50 DEG C, wherein the temperature of the pot wall is 140-155 DEG C, and the carding time is 13-17 minutes during carding of the fixation roasting machine; e, performing final-panning, specifically, stir-frying the pressed strips through a pot typestir-frying machine, wherein the temperature in the pot is 90-100 DEG C, and the final-panning time is 10-12 min; f, improving fragrance: putting the tea leaves into a tea leaf fragrance improving machine, and improving fragrance of the tea leaves through the tea leaf fragrance improving machine; and g, drying in the sun, winnowing, and screening out powder and broken leaves. The process has the advantage of simple process.

Owner:万源市蜀韵生态农业开发有限公司

Preparation method of green tea

PendingCN112237224AEmerald green colorSoup is clear and brightPre-extraction tea treatmentSocial benefitsGreen teas

The invention relates to a preparation method of green tea. The preparation method comprises eight steps of picking, green removal, primary kneading, primary drying, secondary kneading, carding, baking and packaging. According to the Hunan wave green tea prepared by adopting the preparation method provided by the invention, the dry tea is tight, thin and bent in strip, emerald green in color and tippy; and the brewed tea is clear and bright in liquor color, clean and high in fragrance, fresh and cool, mellow and refreshing in taste and yellow-green and bright in leaf bottom. Natural substancecomponents reserved in the Hunan wave green tea have special effects of preventing aging, sterilizing, diminishing inflammation and the like, and are inaccessible to other tea. The preparation methodof the green tea, which is developed by the invention, meets the market requirements, enlarges the tea productivity, and has huge economic and social benefits.

Owner:湘丰茶业集团有限公司 +1

Acid mustard and processing method of acid mustard sauce

ActiveCN103783466BLight colorSoup is clear and brightClimate change adaptationFood preparationAcetic acidEthylene diamine

The invention relates to acid mustard and a processing method of acid mustard sauce. The acid mustard is prepared by cleaning an acid mustard semi-finished product which is primarily pickled and fermented by brine and clear water, and then sealing; taking out the cleaned acid mustard semi-finished product, evenly mixing fresh ginger into the acid mustard semi-finished product, adjusting the concentration of table salt, sealing, and pickling and fermenting for a second time; after that, cooling to low temperature, taking out the product and cutting; and mixing the cut material with clear water, feeding ethylene diamine tetraacetic acid disodium and citric acid, sealing, and sterilizing for a short time at the low temperature. The acid mustard sauce is prepared by cooling the acid mustard semi-finished product which is cleaned as well as pickled and fermented twice, cutting into small pieces, carrying out low-temperature superfine grinding and then sealing, and sterilizing for a short time at the low temperature. The acid mustard produced by the method is light yellow in color, strong in taste, rich in fragrance, clear in soup and long in storage period; the acid mustard sauce is fine and smooth in mouthfeel, strong in taste, rich in fragrance and long in storage period.

Owner:HUNAN DONGTING MINGZHU FOOD CO LTD

Honey snow pear puree and production method thereof

The invention relates to a honey snow pear puree and a production method thereof and belongs to the food processing technology field. The composition of the honey snow-pear puree comprises raw materials of fructose, diced snow pear, water, honey, glycine, edible salt, calcium chloride, sodium pyrosulfite, vitamin C, citric acid, carragheenan, xanthan gum, potassium sorbate, food flavour and white sugar. The frozen diced snow pear is taken as a raw material of the honey snow pear puree; frozen sugaring is carried out by using the fructose; fine honey is added; nutrient loss is avoided to a great degree, and nutrition diversification is ensured. According to the invention, the prepared honey snow pear puree is natural and has gentle flowery flavour and outstanding aroma; the soup color is clear and bright; the taste is rich and mellow; the prepared honey snow pear puree not only can be taken as an ideal raw material for making tea individually, but also for making tea with other scented teas; tea made from the prepared honey snow pear puree not only has delicate fragrance of snow pears, but also has functions of lung moistening and thirst quenching.

Owner:杭州博多工贸有限公司

Preparation method of herba dendrobii green tea

InactiveCN108450629ARound, straight and smoothEmerald green colorTea substituesRetention timeTwo step

The invention discloses a preparation method of herba dendrobii green tea. The method comprises the following steps: reasonably controlling rotation speed of a roller and an enzyme deactivation temperature when enzyme deactivation is carried out; diffusing moisture in herba dendrobii fresh leaves, passivating activity of enzyme, inhibiting enzymatic reaction, and promoting intracellular inclusionin the herba dendrobii fresh leaves to produce a certain chemical change so as to form qualitative characteristics of the green tea to avoid phenomenon of red stems and red leaves as well as focal spots. Sectional twisting is carried out by adopting combination of air pressure twisting and light press twisting when twisting is carried out so that the leaf blades of the herba dendrobii leaves are lightened, the sizes of the leaf blades of the herba dendrobii leaves are reduced, less bald tea and tea byproducts are realized, brewing of the herba dendrobii green tea is convenient, and the concentration of the taste and the richness of a fragrant smell of finished product tea can be effectively improved; the green tea is dried by adopting a two-step drying way when drying is carried out so asto avoid generation of a scorched smell of the tea finished product; spiral angles, which are in a range of 60cm, of the two ends of an enzyme deactivation machine barrel body are greater than 47 degrees, and a spiral angle of the middle section of the enzyme deactivation machine barrel body is smaller than 12 degrees, so that extension of the retention time of the leaf blades of the herba dendrobii leaves can be facilitated, and the quality of the finished product is facilitated.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Cactus tea and production method thereof

InactiveCN108112757AGuaranteed NutrientsThe steps of the production method are simple and quickTea substituesDandelionNutrient

The invention discloses cactus tea. The cactus tea is prepared from the following raw materials in percentage by weight: 68 to 73 percent of cactus, 22 to 27 percent of herba taraxaci and 2 to 7 percent of fructus canarli. By adopting the technical means, the cactus tea provided by the invention has the beneficial effects that the cactus tea combines properties of the cactus and auxiliary raw materials and the raw materials can be sufficiently fused; nutrient elements of the cactus tea are effectively kept and the soup color of brewed tea is clear and bright; the cactus tea is fragrant and elegant, has a fresh and mellow taste and a sweet aftertaste, and has a relatively strong bacterium inhibition effect on influenza virus, adenovirus and streptococcus. A production method of the cactus tea has simple and rapid steps; the production cost is saved and the working efficiency is improved; the production method ensures that the cactus and the auxiliary raw materials are sufficiently fused, so that the quality of the cactus tea is improved.

Owner:习水红四渡仙人掌产业有限公司

Organic tea processing method

InactiveCN102370013BEmerald green colorSoup is clear and brightPre-extraction tea treatmentChemistry

The invention relates to a method for processing tea, in particular to a method for processing organic fragrant tea. The method for processing the organic fragrant tea comprises the processing steps of selecting materials, slightly withering, removing green, cooling, kneading and twisting, drying, winnowing and the like. In the method, processing machines are adopted in the process of processing the tea, so a flow line is formed integrally and yield is increased. The tea processed according to the steps has high quality, durable fragrance, faint fragrance slightly with orchid fragrance, strip-shaped, curled and attractive appearance, jade green color, flowers at the bottom of the tea, clear and bright soup color, and fresh and mellow taste.

Owner:浙江银奥茶业发展有限公司

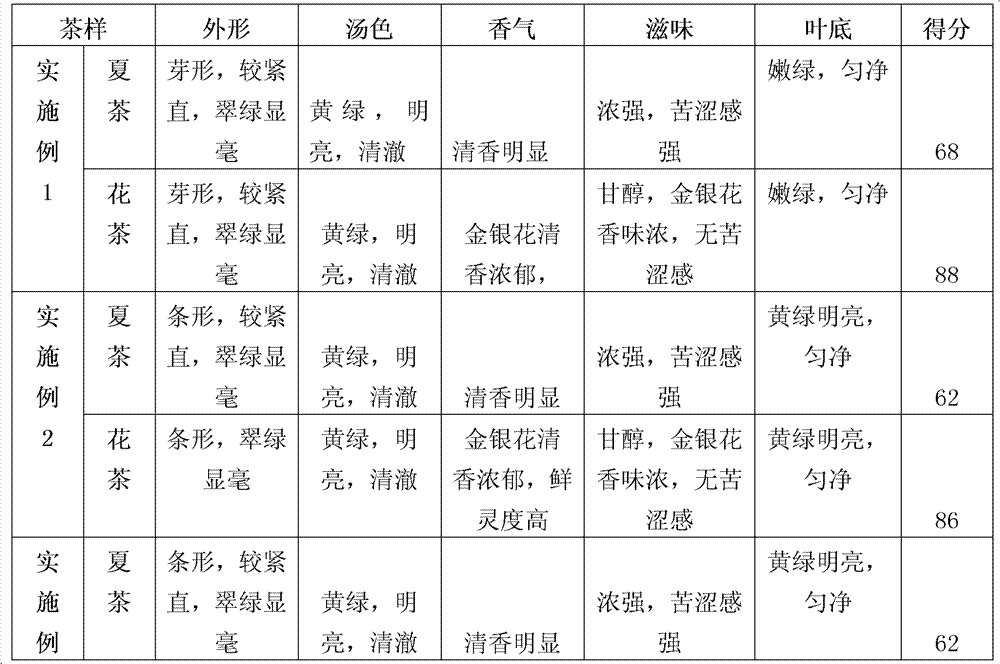

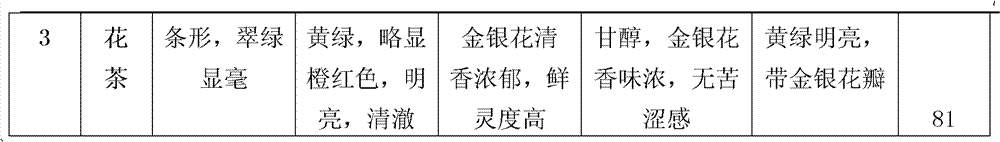

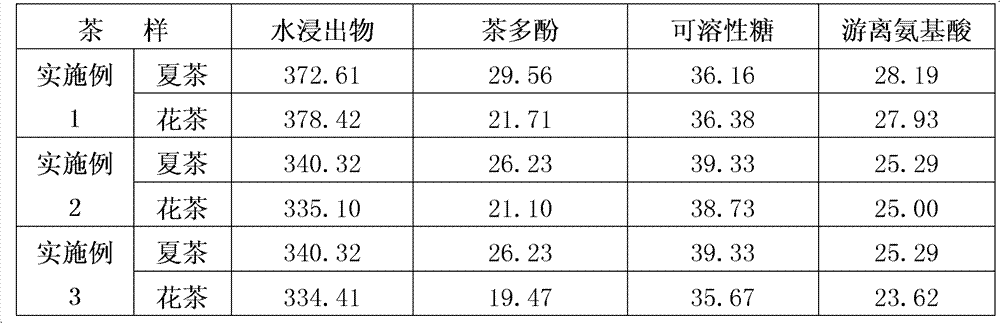

Honeysuckle tea and scenting method for same

ActiveCN102524456BImprove qualityImprove taste qualityPre-extraction tea treatmentGreen teasTea leaf

The invention belongs to the technical field of tea processing, in particular to scented tea and a scenting method for the same. The honeysuckle tea is characterized by being prepared by scenting summer tea, blooming honeysuckle and magnolia flower, wherein the adding amount of the blooming honeysuckle is 100 percent of the mass of the summer tea; the adding amount of the magnolia flower is 1 percent of the mass of the summer tea; and the summer tea is prepared from fresh leaves of summer tea trees, which have the specification of a single bud or a bud and a leaf, by a green tea processing technology. By the method, the summer tea resources can be promoted to be developed and utilized, and the obtained honeysuckle tea has good quality.

Owner:HUBEI WUDAO TEA IND

A kind of functional prickly pear beverage and preparation method thereof

The invention provides a functional roxburgh rose drink and a preparation method thereof. The functional roxburgh rose drink is prepared from roxburgh rose, glutinous rice, sorghum, bran, a sodium carbonate water solution with the concentration of 0.6%, a yeast, sodium benzoate, potassium sorbate, tannase, citric acid, sucrose and purified water. The functional roxburgh rose drink is good in quality, bright and clear in soup, not easy to oxidize or brown, balanced in nutrients, good in taste, free of an astringent taste, and also has the effects of strengthening the physique and improving the immunity of the organism.

Owner:贵州恒力源天然生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com