Method of creation of celery leaf tea

A production method and celery leaf technology are applied in the production field of celery leaf semi-fermented tea, and can solve the problems of waste of celery leaf resources, failure to realize comprehensive utilization value of celery, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

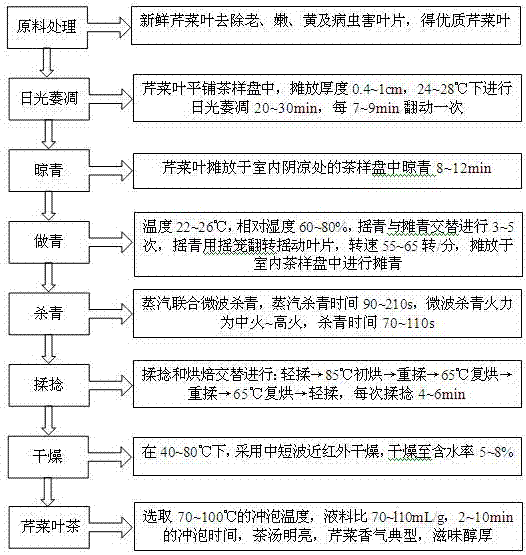

[0037] The step of a kind of preparation method of celery leaf tea is:

[0038] 1) Fresh celery leaves are removed from old, tender, yellow and pest-infested leaves;

[0039] 2) Wither the celery leaves obtained in step 1): Spread them flat on the tea sample tray with a thickness of 1 cm, wither in sunlight for 30 minutes at a temperature of 28°C, and turn the celery leaves every 9 minutes to obtain withered celery leaves;

[0040] The weight loss rate of celery leaves is controlled at a suitable level of 16.02%, the luster of the leaf surface disappears, and it turns dark green and slightly soft, which is suitable for subsequent processes;

[0041] 3) Spread the withered celery leaves in a tea sample tray in a cool place indoors and dry them for 12 minutes to obtain dried green celery leaves;

[0042] The weight loss rate is controlled at a suitable level of 6.58%. The moisture in each part of the celery leaf is redistributed evenly, the heat is distributed between the leave...

Embodiment 2

[0060] The step of a kind of preparation method of celery leaf tea is:

[0061] 1) Fresh celery leaves are removed from old, tender, yellow and pest-infested leaves;

[0062] 2) Wither the celery leaves obtained in step 1): Spread them flat on a tea sample tray with a thickness of 0.5cm, wither in sunlight for 25 minutes at a temperature of 26°C, and turn the celery leaves every 8 minutes to obtain withered celery leaves ;

[0063] The weight loss rate of celery leaves is controlled at a suitable level of 11.76%, the gloss of the leaf surface disappears, turns dark green, slightly soft, and is suitable for subsequent processes;

[0064] 3) Spread the withered celery leaves in a tea sample tray in a cool place indoors and dry them for 10 minutes to obtain dried green celery leaves;

[0065] Spread the celery leaves after withering in tea sample trays in a cool place indoors to dry green respectively. The bamboo tea sample tray is used because it is natural and clean, which c...

Embodiment 3

[0087] The step of a kind of preparation method of celery leaf tea is:

[0088] 1) Fresh celery leaves are removed from old, tender, yellow and pest-infested leaves;

[0089] 2) Wither the celery leaves obtained in step 1): Spread them flat on a tea sample tray with a thickness of 0.4cm, wither in sunlight for 20 minutes at a temperature of 24°C, and turn the celery leaves every 7 minutes to obtain withered celery leaves ;

[0090] The weight loss rate of celery leaves is controlled at a suitable level of 10.57%, and the gloss of the leaves disappears, turning dark green and slightly soft, which is suitable for subsequent processes.

[0091] 3) Spread the withered celery leaves in a tea sample tray in a cool place indoors and dry them for 8 minutes to obtain dried green celery leaves;

[0092] The weight loss rate is controlled at a suitable level of 4.58%. The water redistribution in each part of the celery leaf is even, the heat is dissipated between the leaves, and the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com