Variable-speed rolling process of curly green tea

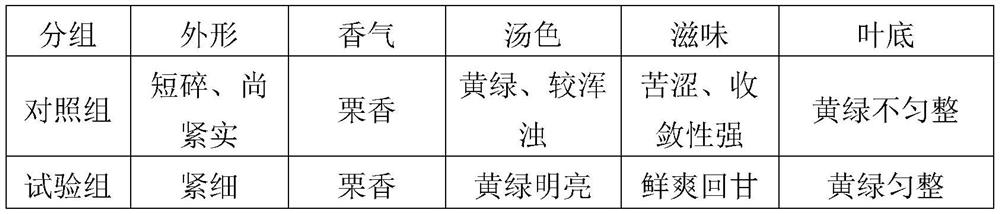

A green tea and curling technology is applied in the field of variable-speed rolling technology of curling green tea, which can solve the problems of low rate of refining into tea, "ungreen color and bitter taste of tea leaves, etc." The effect of substance content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The fresh leaves of the tea are picked for spreading and killing. A 60-type drum-type continuous killing machine is used. The fixing temperature is 220°C and the killing time is 70 seconds. The amount of water is 55%.

[0020] After finishing, carry out the first variable speed kneading, adopt 55 type kneading machine, throwing leaves is suitable for 90% of kneading barrel capacity, the first step is air pressure for 15 minutes, the speed is 50 rpm; the second step is light pressure for 10 minutes, The rotation speed is 46 rpm; the third step is medium pressure for 10 minutes, and the rotation speed is 42 rpm; the fourth step is air pressure for 5 minutes, and the rotation speed is 44 rpm. After the first variable-speed kneading, dry the tea leaves for the second time. Use a continuous dryer or a drum frying machine at a temperature of 120°C for 5 minutes. After the second drying, the tea leaves will feel a little prickly and the color of the leaves will become dark. ,...

Embodiment 2

[0023] The fresh leaves of the tea are picked for spreading and killing. A 60-type drum-type continuous killing machine is used. The fixing temperature is 220°C and the killing time is 70 seconds. The amount of water is 60%.

[0024] After finishing, carry out the first variable speed kneading, adopt 55 type kneading machine, throwing leaves is suitable for 90% of kneading barrel capacity, the first step is air pressure for 15 minutes, the speed is 50 rpm; the second step is light pressure for 10 minutes, The rotation speed is 46 rpm; the third step is medium pressure for 10 minutes, and the rotation speed is 42 rpm; the fourth step is air pressure for 5 minutes, and the rotation speed is 44 rpm. After the first variable speed kneading, dry the tea leaves for the second time. Use a continuous dryer or a drum frying machine at a temperature of 125°C for 6 minutes. , the stems are still green. Cool and stack the tea until the moisture is redistributed evenly. Then use the 6CR...

Embodiment 3

[0027] The fresh leaves of the tea are picked for spreading and killing. A 60-type drum-type continuous killing machine is used. The fixing temperature is 220°C and the killing time is 70 seconds. The amount of water is 65%.

[0028] After finishing, carry out the first variable speed kneading, adopt 55 type kneading machine, throwing leaves is suitable for 90% of kneading barrel capacity, the first step is air pressure for 15 minutes, the speed is 50 rpm; the second step is light pressure for 10 minutes, The rotation speed is 46 rpm; the third step is medium pressure for 10 minutes, and the rotation speed is 42 rpm; the fourth step is air pressure for 5 minutes, and the rotation speed is 44 rpm. After the first variable speed kneading, dry the tea leaves for the second time, using a continuous dryer or a drum frying machine at a temperature of 130°C for 8 minutes. After the second drying, the tea leaves will feel a little prickly and the color of the leaves will become dark. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com