Steel angel set, steel channel set for splicing of timber formwork, and construction method

A construction method and wood formwork technology, which is applied in the field of channel steel sets for splicing wood formwork and angle steel sets for splicing wood formwork, and can solve the problems of easily damaged formwork, reduced turnover rate of formwork, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

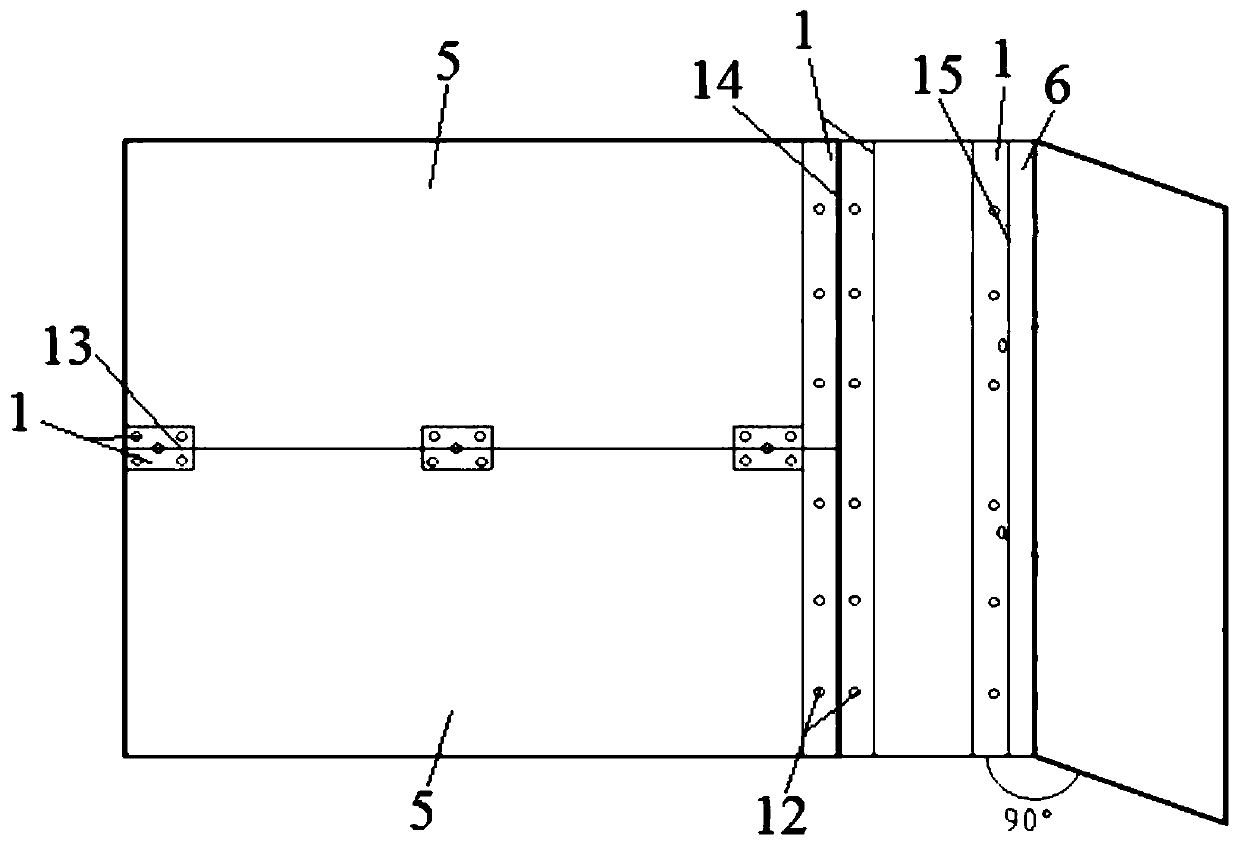

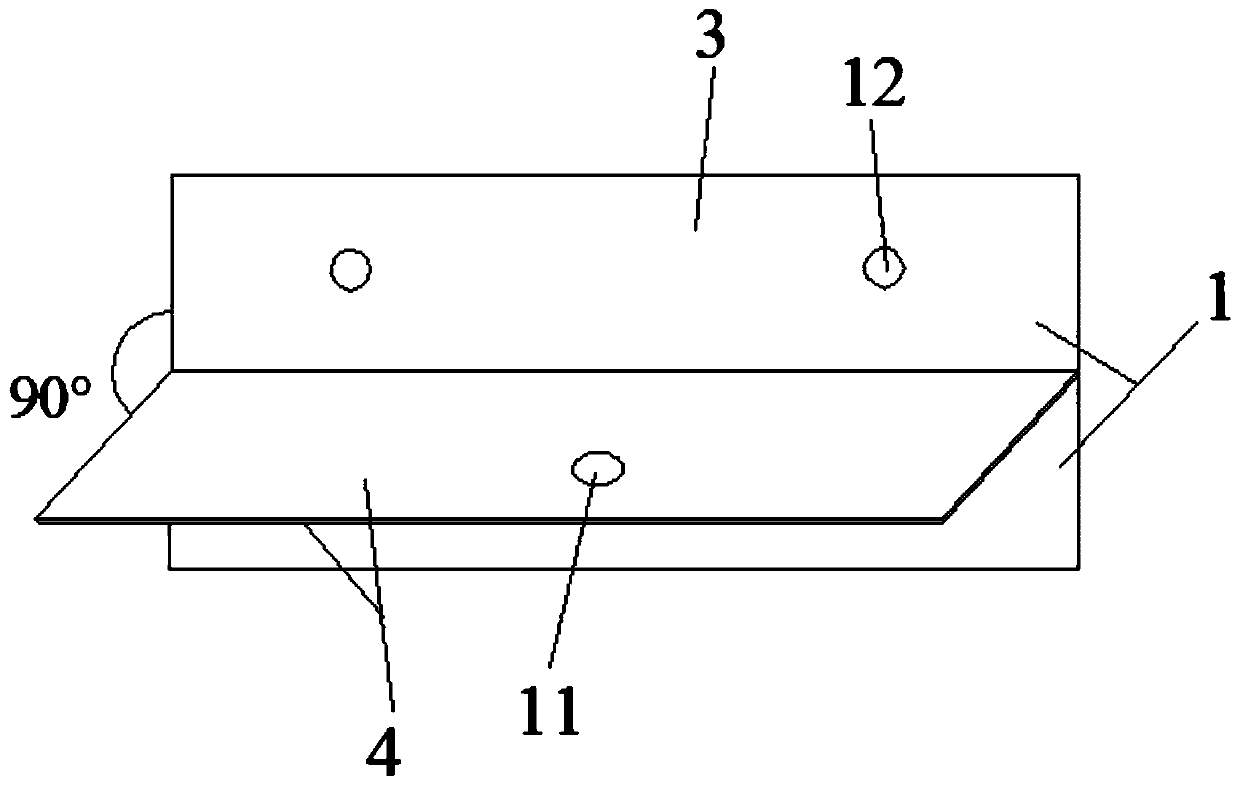

[0041] Such as figure 1 and figure 2 as shown, figure 2 It is a structural schematic diagram of the horizontal splicing 13 of the angle steel 1 set, a wooden formwork 5 splicing angle steel 1 set, including two angle steels 1 and several steel pins 2, and each angle steel 1 includes a first side 3 and a second side perpendicular to each other. Two sides 4, the first sides 3 of the two angle steels 1 are respectively used to connect two wooden templates 5, the second sides 4 of the two angle steels 1 are fixedly connected to each other by a plurality of steel pins 2 and spliced together Form a T-shaped member.

[0042] A second through hole 12 is provided on the first side 3, and the second through hole 12 is used for bolt connection.

[0043] Such as image 3 As shown, the structural schematic diagram of the vertical splicing 14, the splicing principle is the same as the horizontal splicing 13, but the placement position of the wooden formwork 5 is different.

[0044]...

Embodiment 2

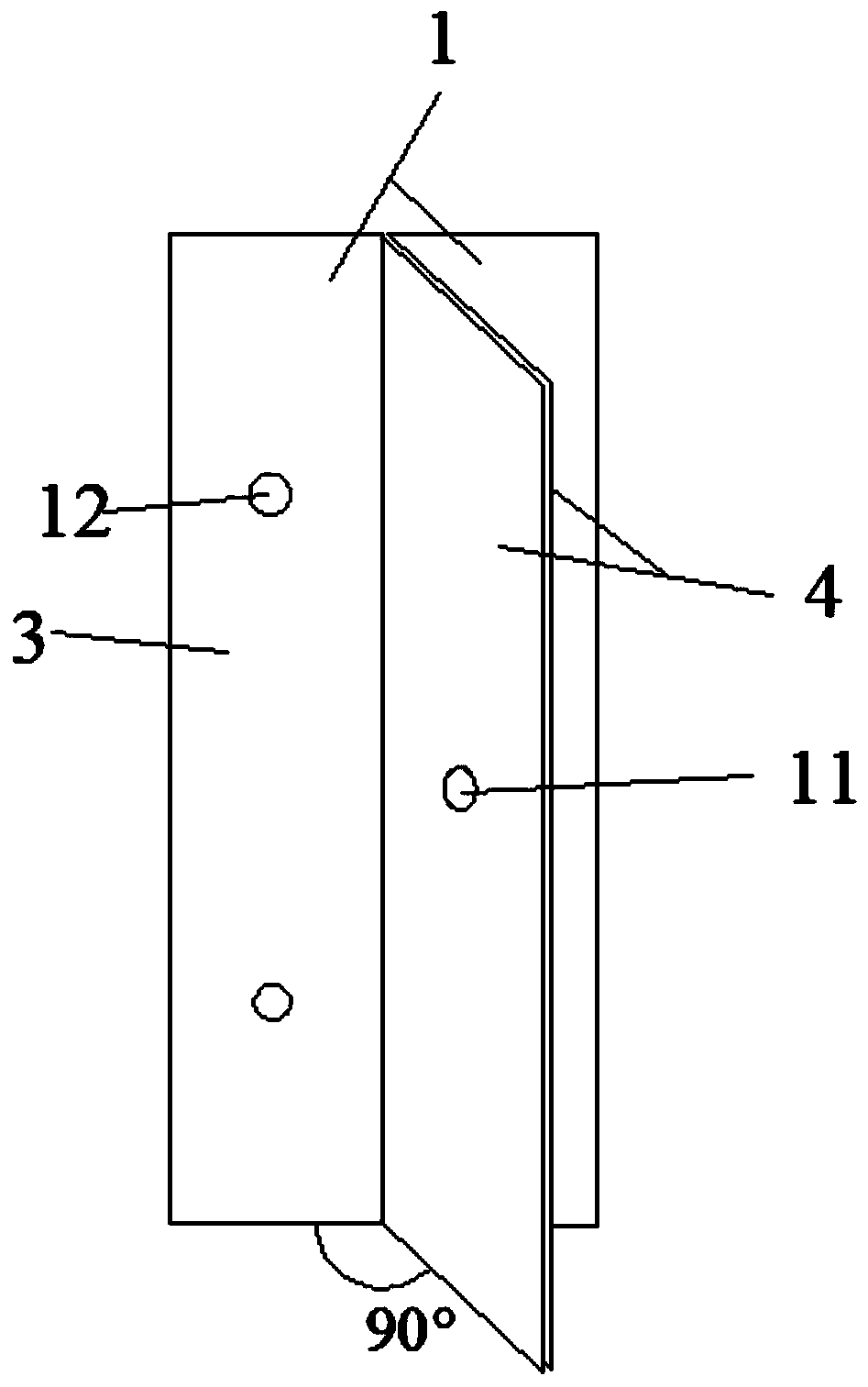

[0048] Such as figure 1 and Figure 7 as shown, Figure 7 It is a structural schematic diagram of the vertical splicing 15 of the channel steel 6 sets, a channel steel set for wooden template splicing, including an angle steel 1 and a channel steel 6, and the angle steel 1 includes a first side 3 and a second side 4 perpendicular to each other, The channel steel 6 includes a bottom end and a first end 7 and a second end 8 vertically connected to both sides of the bottom end, the first side 3 of the angle steel 1 and the first end 7 of the channel steel 6 are respectively used for connecting When two wooden templates 5 are vertically spliced 15, the second side 4 of the angle steel 1 and the second end 8 of the channel steel 6 are spliced with each other, and fixed and spliced with each other by a plurality of steel pins 2 to form an F-shaped member.

[0049] Steel pin 2 in embodiment 2 is identical in structure and function with steel pin 2 in embodiment 1;

[0050] S...

Embodiment 3

[0054] A kind of wooden template 5 splicing construction method, following steps:

[0055] The first step is to customize angle steel 1 and channel steel 6, customize angle steel 1 and channel steel 6 of different specifications according to the construction area, and make the first through hole 11 and the second through hole 12;

[0056] The second step is to customize the steel pins 2, determine the quantity of the steel pins 2 according to the quantity of the first through holes 11, and make the same number of steel pins 2;

[0057] The third step, flatness inspection, check the flatness of angle steel 1 and channel steel 6, and check whether the size and bending angle of angle steel 1 and channel steel 6 meet the requirements;

[0058] The fourth step, check the hole position, check the opening positions of the angle steel 1 and the channel steel 6, check whether the opening positions are aligned, and ensure the splicing quality of two identical angle steel 1, and the angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com