A novel synchronous measuring device for the height and phase angle of the helical element

A technology for component height and synchronous measurement, which is applied in measurement devices, mechanical measurement devices, angle/taper measurement, etc. It can solve the corresponding relationship between the split height and the phase angle of the helical section, the error between the height and the phase angle of the helical section, and the low measurement efficiency. problems, to achieve the effect of reasonable measurement process structure, improve product quality, and reasonable process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

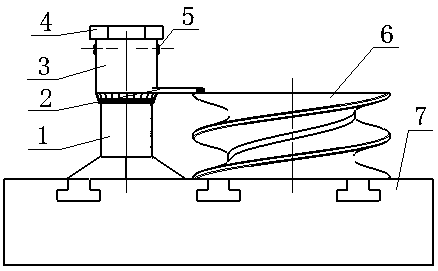

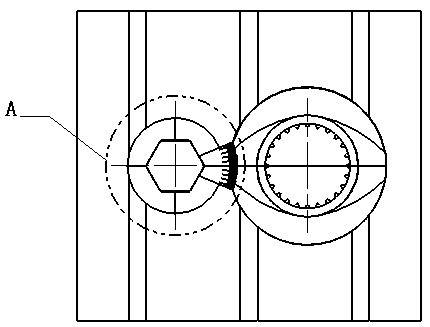

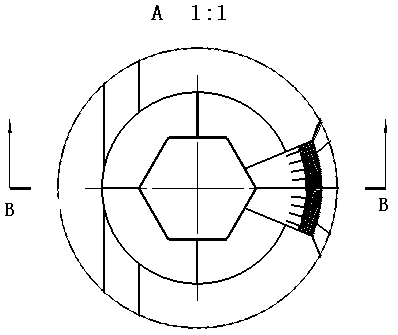

[0018] like Figure 1 to Figure 7 As shown, the new type of synchronous measuring device for the height and phase angle of the helical element includes a height measuring seat 1, a tooth measuring plate 2, an angle measuring sleeve 3, a screw rod 4, a set pin 5, a helical element 6 and a working platform 7, and the helical element 6 Position on the working platform 7, move the height measuring seat 1 on the working platform, place the fan-shaped bottom plane of the sector tooth measuring plate 2 on the upper plane of the height of the spiral element, rotate the measuring teeth on the sector tooth measuring plate 2, and make the sector bottom The plane touches the upper plane of the helical element horizontally, the phase angle of the measuring tooth rotation on the sector tooth measuring plate 2 is the same phase angle as the angle measuring sleeve 3 rotates synchronously, and the angle scale reading on the angle measuring sleeve 3 is at the height measuring seat 1 Correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com