Method for effectively removing dust of printer

A technology for printers and dust, applied in printing devices, printing, etc., can solve the problem of low efficiency in cleaning dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

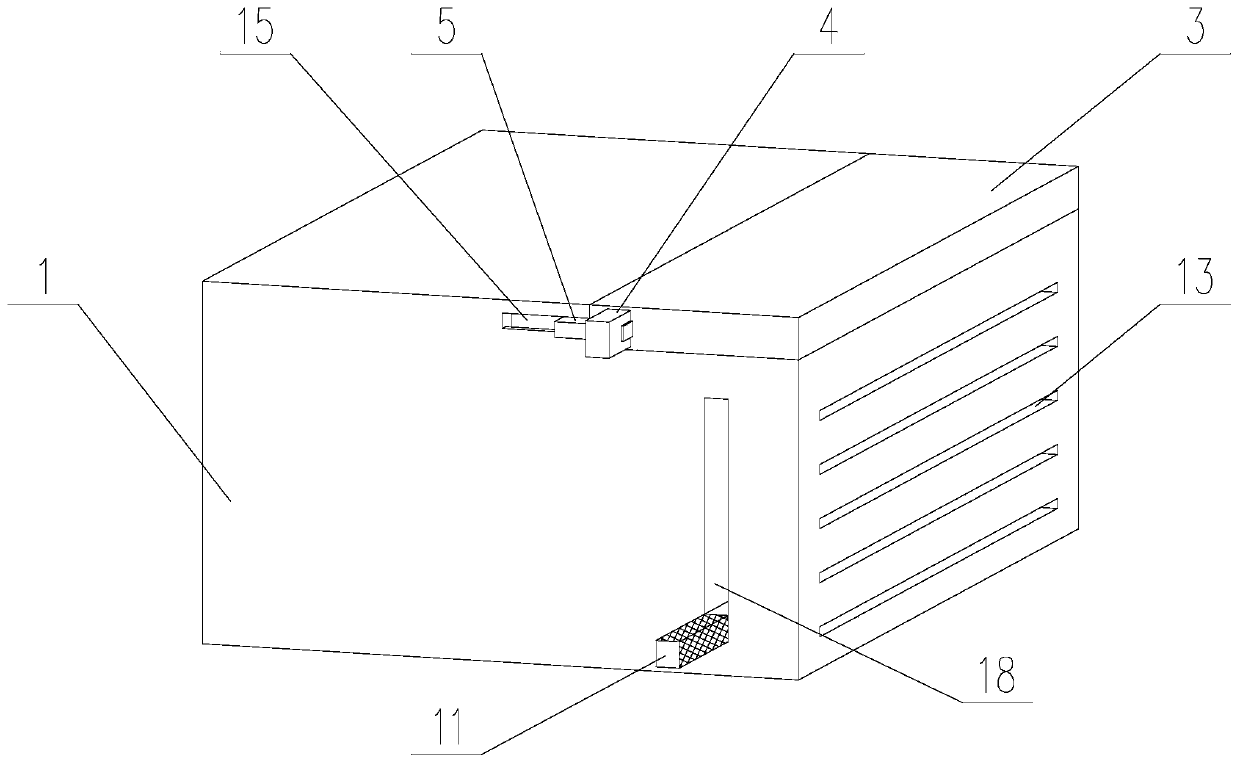

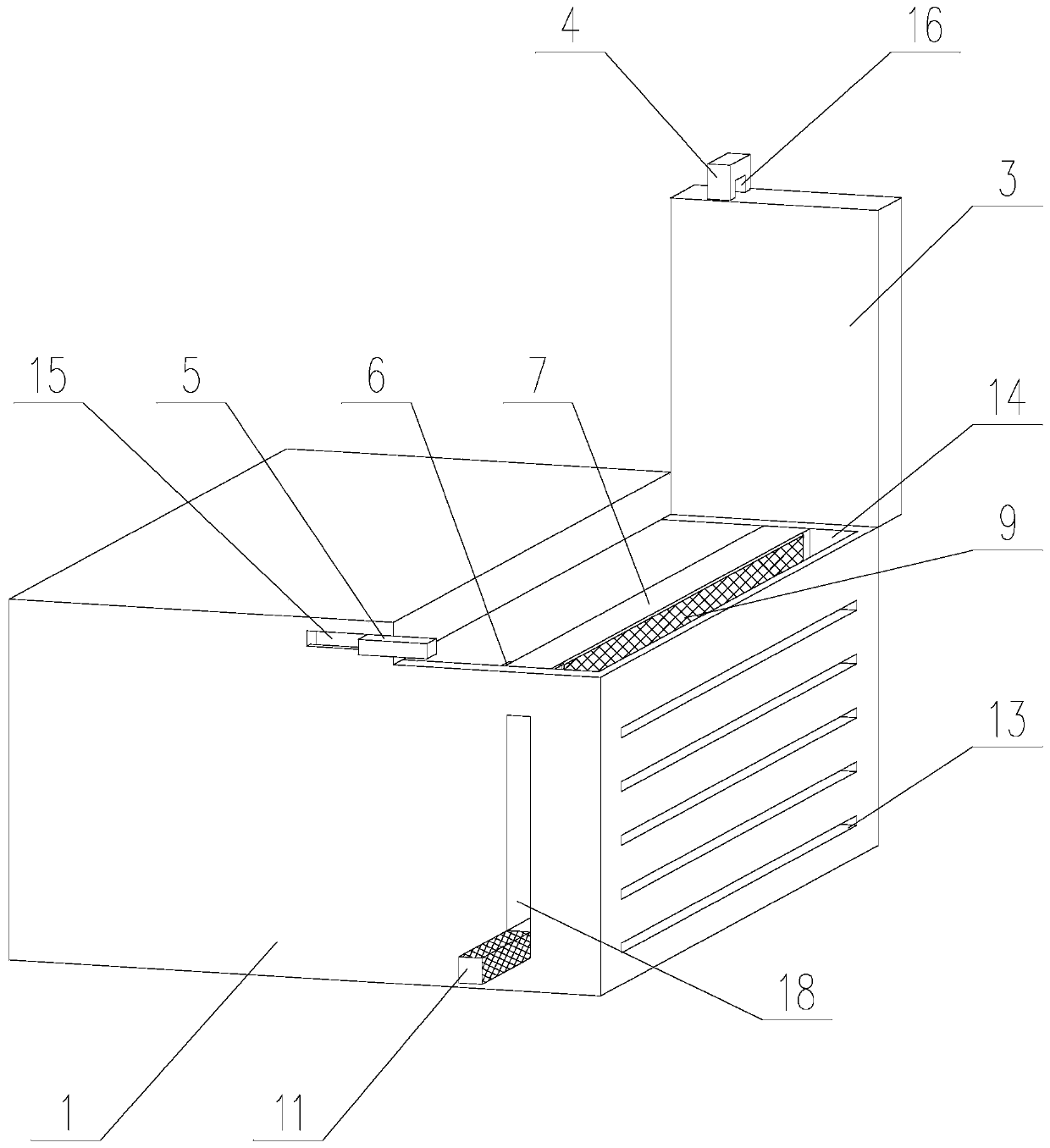

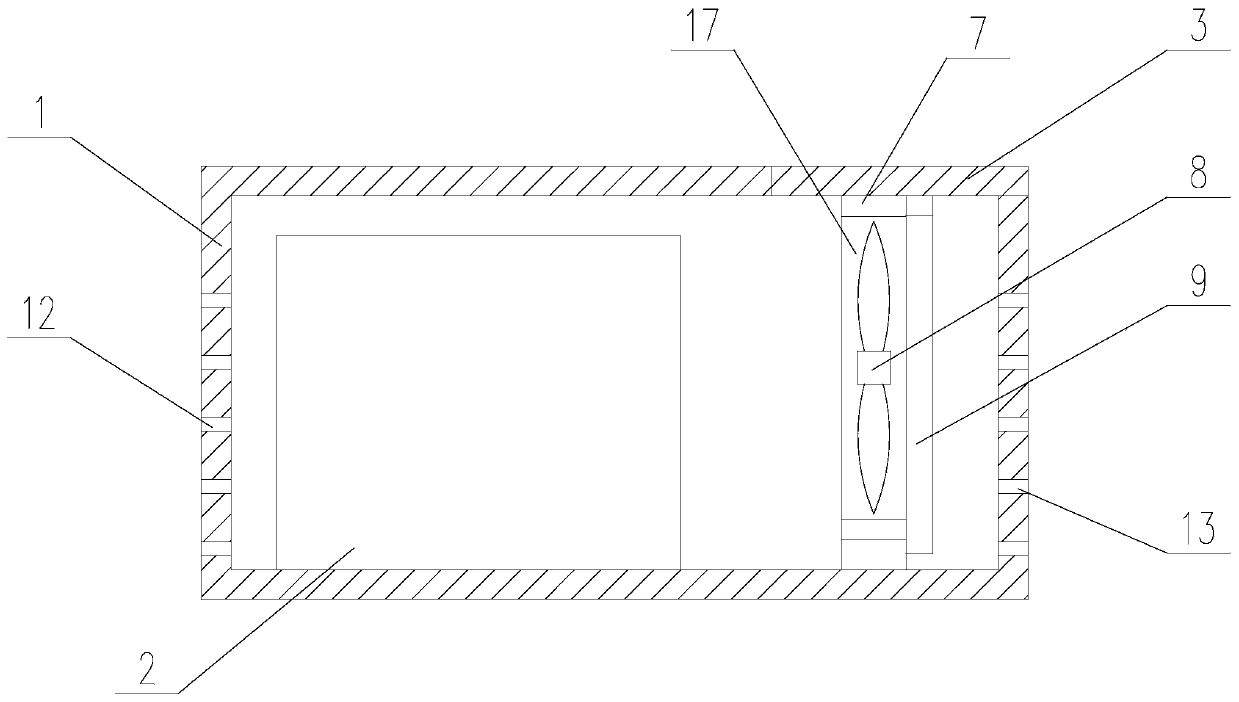

[0039] A method for effectively cleaning printer dust, comprising a box body 1 and a printer body 2 placed inside the box body 1, and air inlets 13 and air outlets communicating with the inside of the box body are respectively provided on both sides of the box body 1 12. A dust removal device is provided between the printer main body 2 and the air inlet 13, and the dust removal device includes a movable plate 3, a movable block, a fixed rod 5, a matching block 4, a connecting block 6, an installation block 7, and a fan device 8 and dust filter 9,

[0040] An installation hole 14 is provided on the top surface of the box body 1 away from the printer body 2, the bottom of the installation hole 14 communicates with the inside of the box body 1, and one end of the movable plate 3 is connected to the end surface of the installation hole 14. One side is hinged, the hinge axis between the movable plate 3 and the box body 1 is parallel to the ground, the movable plate 3 covers the ins...

Embodiment 2

[0051] A specific implementation description is made for the operation mode in Embodiment 1.

[0052] Such as figure 2 As shown, in the present invention, a fixed plate 10 is provided inside the box body 1, and the control rod 11 passes through the side wall of the box body 1 to connect with the fixed plate 10. The user can push the control rod 11 along the movable groove 18 to control the fixed plate. 10, use the fixed plate 10 to control the position of the installation block 7. When the installation block 7 needs to be taken out, the user can clamp it from the side where the installation block 7 is in contact with the side wall of the box body 1, so as to avoid taking out the installation block 7. To be in contact with the dust-proof net 9, causing the dust to fall inside the casing 1, it is inconvenient to clean up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com