A processing method of hyperboloid forming equipment

A processing method and hyperboloid technology, applied in the field of shipbuilding, can solve the problems of high precision requirements, complex structure of semi-submersible lifting and dismantling platforms, and difficult construction, and achieve guaranteed accuracy, better product quality, and good confirmation. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

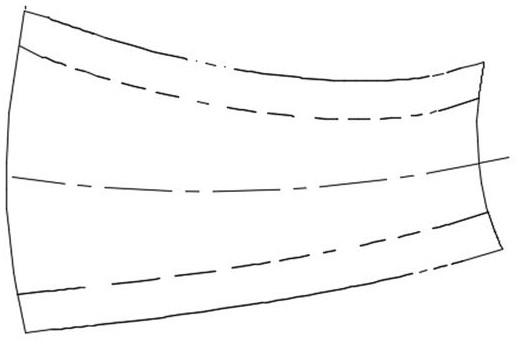

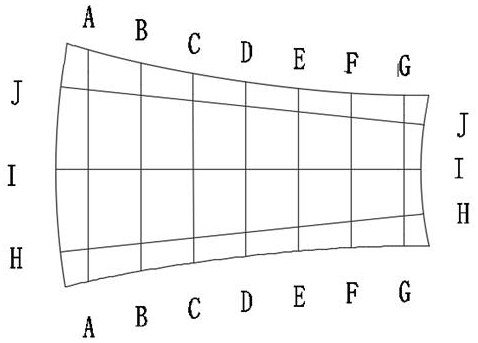

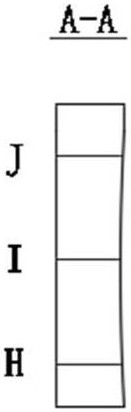

[0065] Such as Figure 1-13 As shown, a processing method for hyperboloid forming equipment includes the following steps:

[0066] Step 1: Establish the mechanical model of cold forming and study the mechanical properties of special plates: combine the yield criterion of plate materials and the constitutive equation of elastic-plastic finite element method, solve the mechanical equation of cold forming, and derive the springback radius of material forming;

[0067] Step 2: Fitting the surface of the double-curvature plate and mathematically characterizing it;

[0068] Step 3: finite element numerical simulation to determine the rebound amount of the shape of the double-curvature molding die; Step 4: Processing and manufacturing the outer plate of the curved plate die, and making a set of outer plates at intervals of 500mm according to the curvature of the fitted hyperboloid. The upper mold with the same plate curvature, different upper molds are made according to different cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com