Magnetic stripe obtaining and storing mechanism

A magnetic strip and magnetic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low efficiency and precision, and achieve the effect of low efficiency, high precision and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

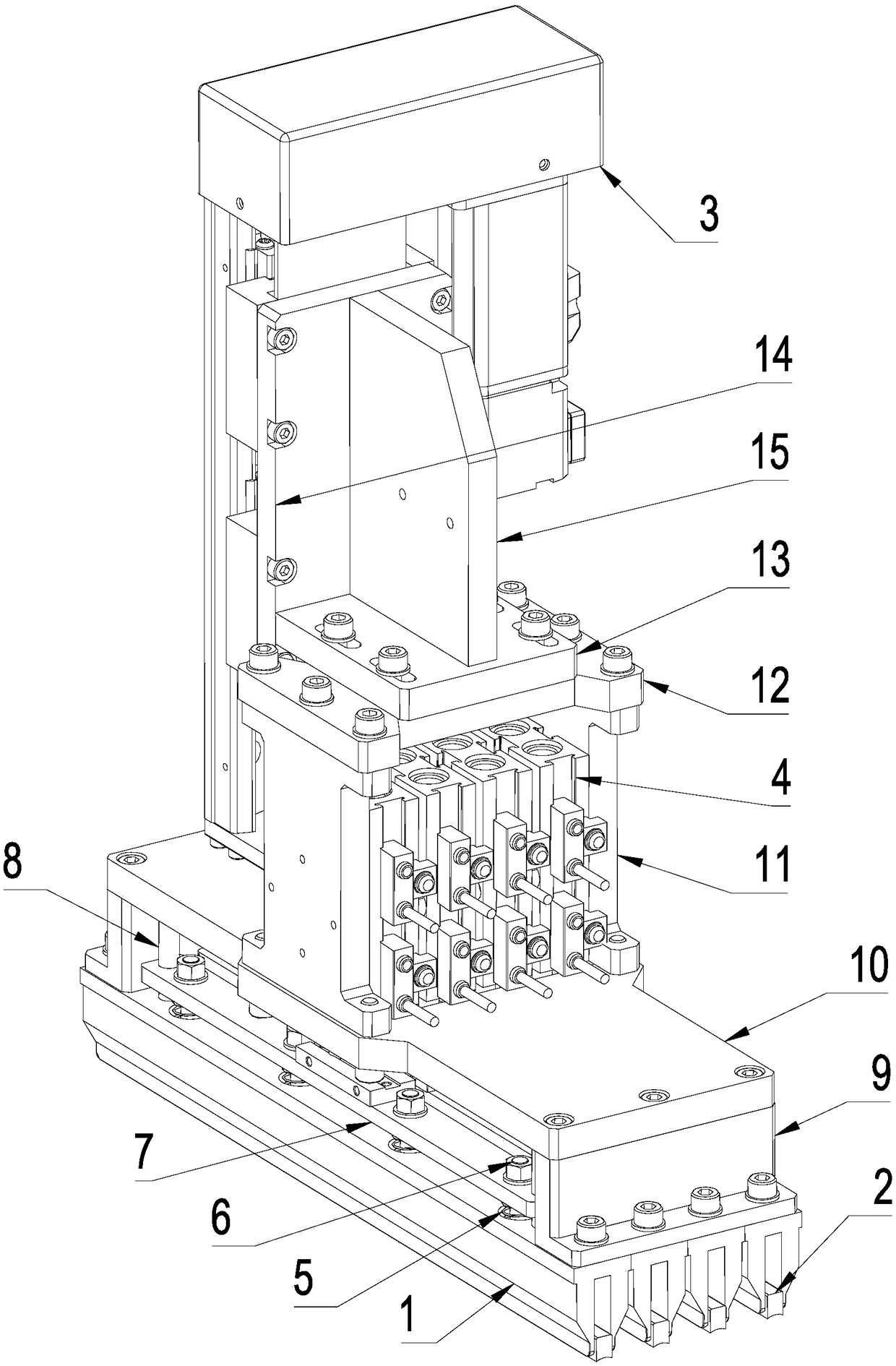

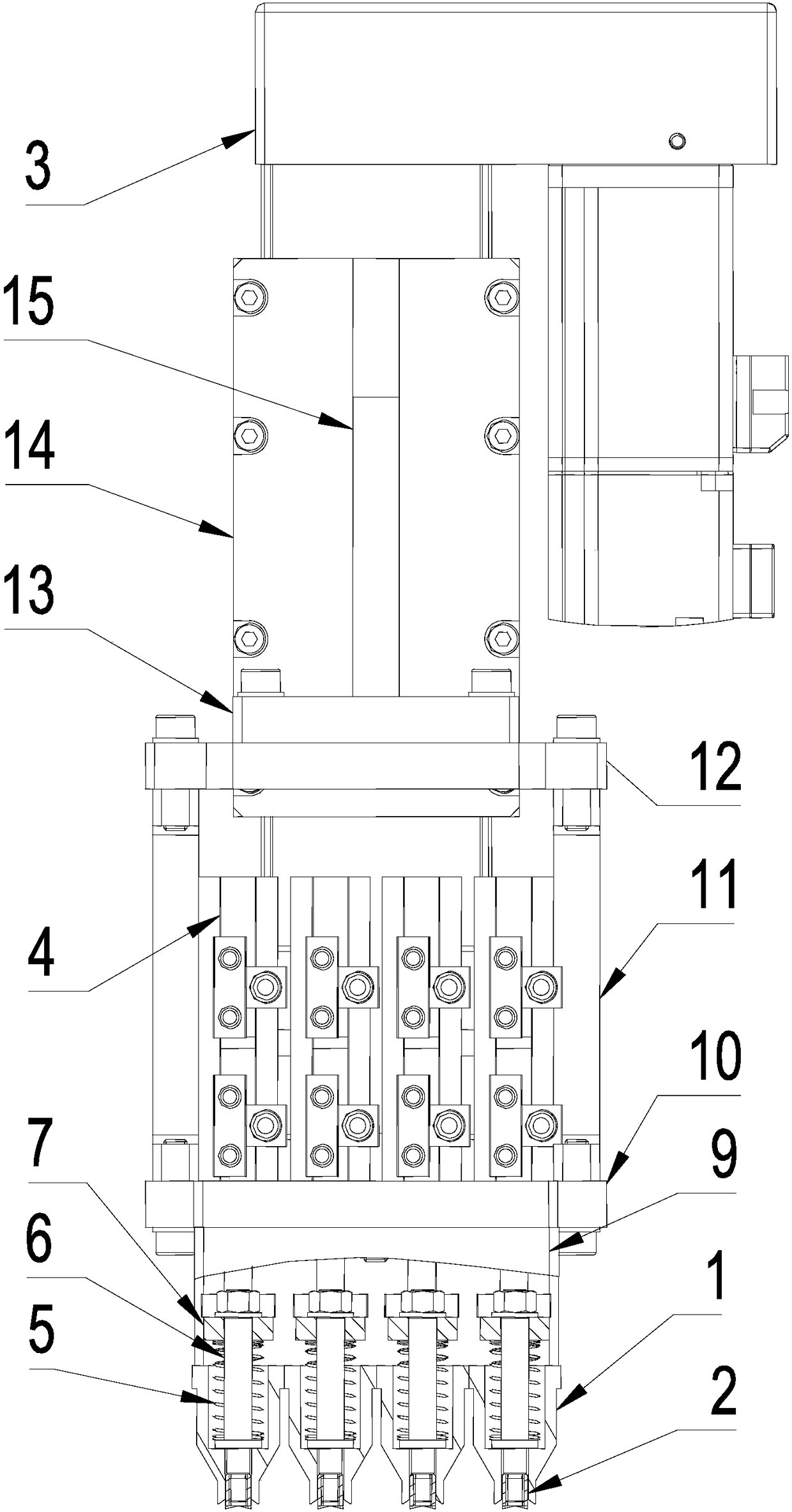

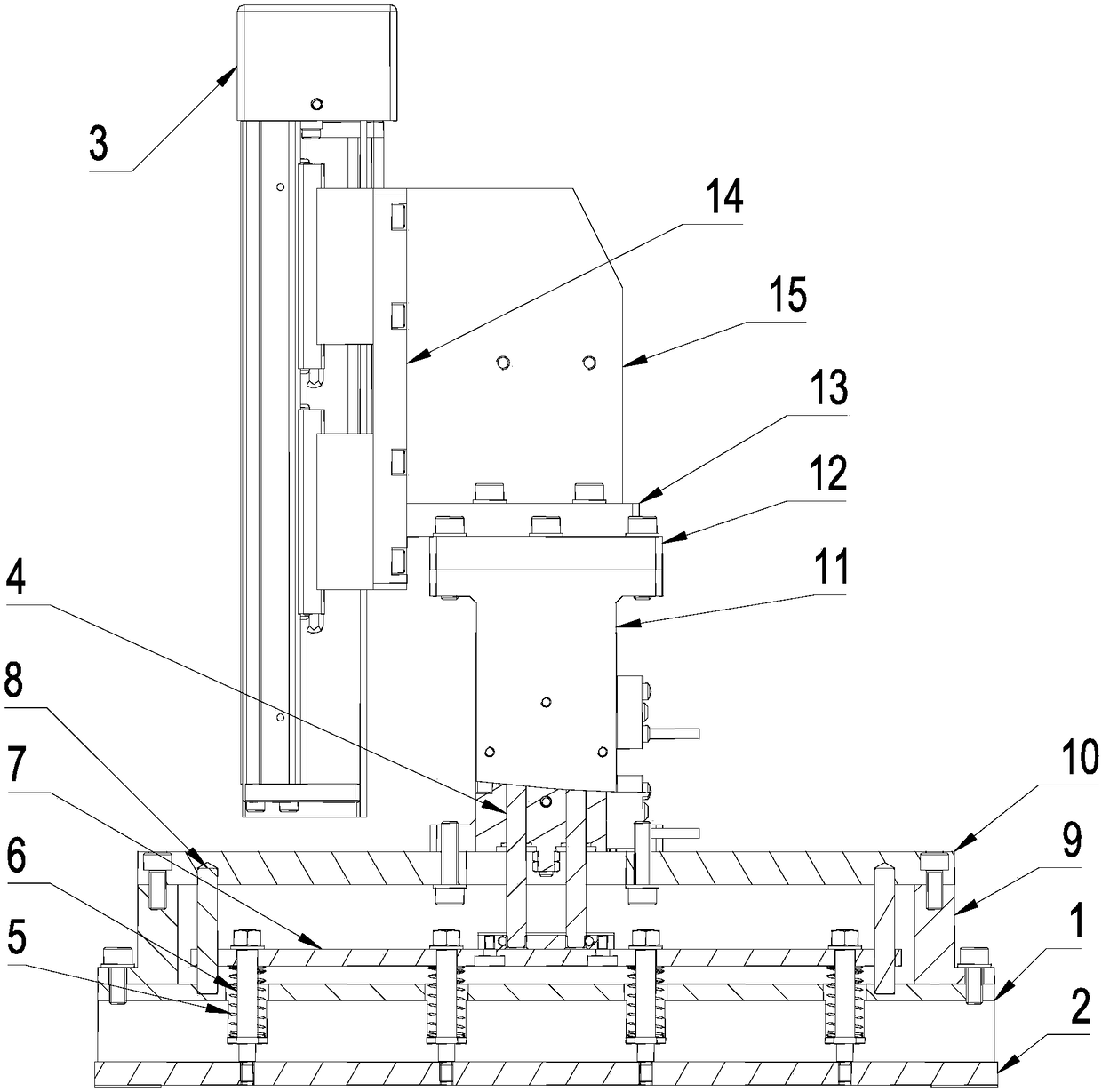

[0019] Such as Figure 1 to Figure 3 As shown, a magnetic strip pick-and-place mechanism is provided with at least four fetching blocks 1, and the fetching block 1 is connected with a linear module 3, and the fetching block 1 moves up and down as a whole under the drive of the linear module 3, which is convenient for fetching material. A suction block 2 is arranged at the center of each material fetching block 1, and the suction block 2 can absorb magnetic strips. At least two guide screws 6 are arranged on each suction block 2, and the upper end of the guide screws 6 on the suction block 2 is connected to a pull plate 7 at the same time, and the pull plate 7 is connected to a cylinder 4, and the suction block 2 rises simultaneously under the drive of the cylinder 4 to realize The release of the magnetic stripe.

[0020] The specific action principle of the present invention is that when absorbing the magnetic strip, the linear module 3 drives the retrieving block 1 to desce...

Embodiment 2

[0023] Such as Figure 1 to Figure 3 As shown, a magnetic strip pick-and-place mechanism is provided with at least four fetching blocks 1, and the fetching block 1 is connected with a linear module 3, and the fetching block 1 moves up and down as a whole under the drive of the linear module 3, which is convenient for fetching material. A suction block 2 is arranged at the center of each material fetching block 1, and the suction block 2 can absorb magnetic strips. At least two guide screws 6 are arranged on each suction block 2, and the upper end of the guide screw 6 on each suction block 2 is connected to an independent pull plate 7 at the same time, and each pull plate 7 is connected to a cylinder 4, so that each suction block 2 Driven by a cylinder 4, it can be raised separately to realize simultaneous or separate release of the magnetic strips.

[0024] The specific action principle of the present invention is that when absorbing the magnetic strip, the linear module 3 d...

Embodiment 3

[0027] Such as Figure 1 to Figure 4 As shown, a magnetic strip pick-and-place mechanism is provided with at least four fetching blocks 1, and the fetching block 1 is connected with a linear module 3, and the fetching block 1 moves up and down as a whole under the drive of the linear module 3, which is convenient for fetching material. A suction block 2 is arranged at the center of each material fetching block 1, and the suction block 2 can absorb magnetic strips. At least two guide screws 6 are arranged on each suction block 2, and at least two springs 5 are sheathed on the guide screws 6, so that the suction block 2 has certain flexibility. The upper end of the guide screw 6 on each suction block 2 is connected to an independent pull plate 7 at the same time, and each pull plate 7 is connected to a cylinder 4, so that each suction block 2 can rise independently under the drive of a cylinder 4 to realize the alignment of the magnetic strips. simultaneously or separately. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com