UV (ultraviolet)-curable acrylate polymer water emulsion for coating polypropylene film

A technology of polypropylene film and acrylate, applied in the direction of coating, etc., can solve the problems of poor bonding performance between coating resin and BOPP substrate, weak cohesion of resin molecules, excessive polarity and surface energy, etc., to improve spreading performance , strong cohesion, and easy system viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

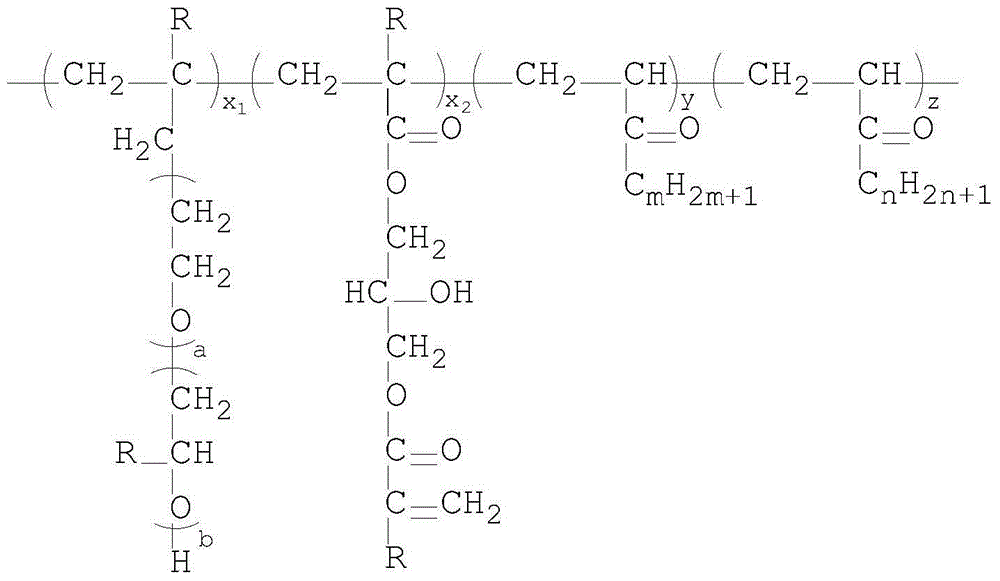

[0045] Embodiment 1: the preparation of UV photocurable acrylate polymer aqueous emulsion for polypropylene film coating

[0046] Preparation of water-based acrylate prepolymer emulsion: by weight ratio, add 150 parts of ethylene glycol monomethyl ether, 5 parts of allyl polyoxyethylene ether (molecular weight 5000), 5 parts Parts of methacrylic acid, 60 parts of lauryl acrylate, 30 parts of methyl acrylate, 2 parts of azobicyclohexylcarbonitrile, after heating up to 75°C for 10 hours, add 0.5 parts of 2,5-di-tert-butylhydroquinone , 0.2 parts of tetrabutyl ammonium fluoroborate, add 8 parts of glycidyl methacrylate, continue to react at 102°C for 4 hours, remove the solvent to obtain a water-based acrylate prepolymer; dissolve it in 200 parts of water, and heat Stir for 10min to obtain an aqueous acrylate prepolymer emulsion;

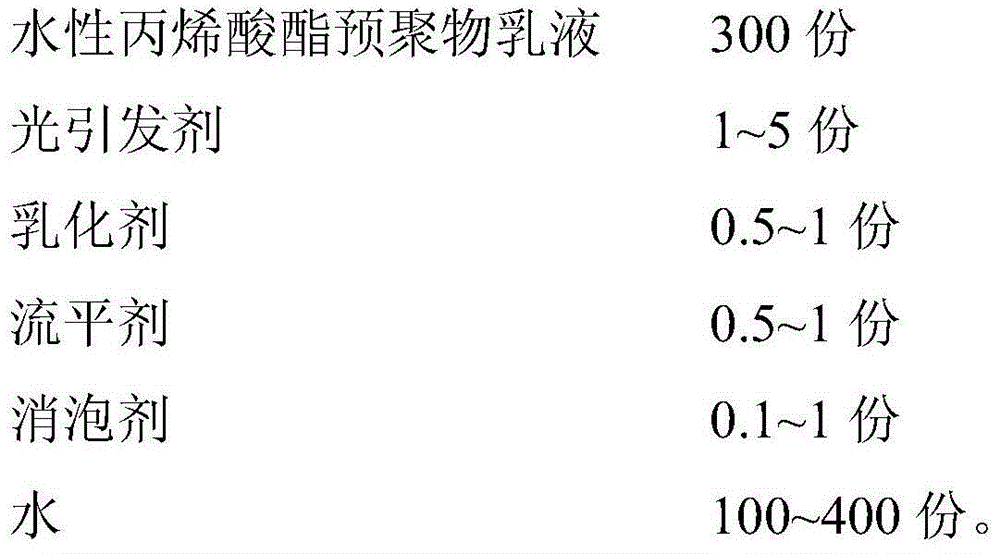

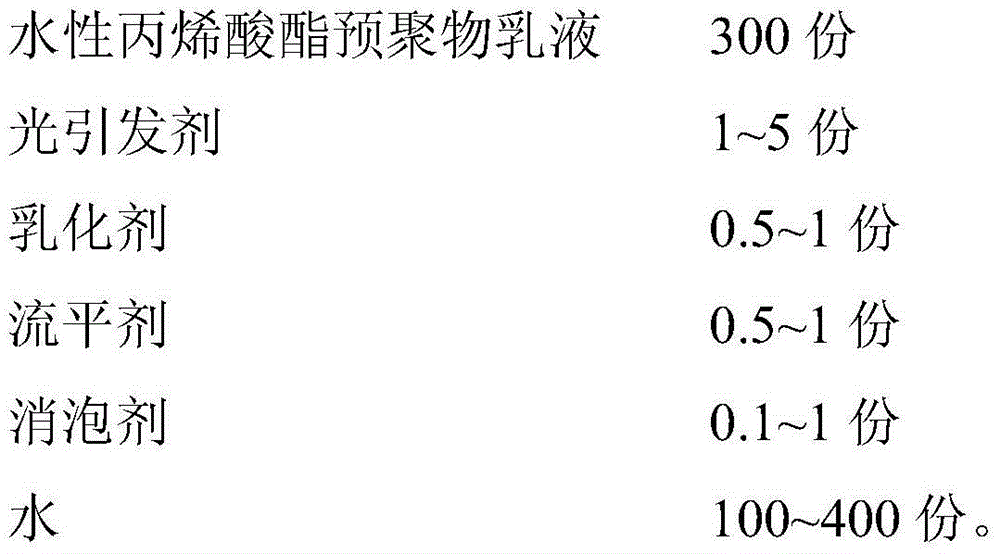

[0047] Preparation of UV-curable acrylate polymer aqueous emulsion: Take 300 parts of the above-mentioned aqueous acrylate prepolymer emulsion, add 1...

Embodiment 2

[0050] Embodiment 2: the preparation of UV photocurable acrylate polymer aqueous emulsion for polypropylene film coating

[0051] Preparation of water-based acrylate prepolymer emulsion: by weight, add 200 parts of cyclohexanone and 20 parts of methallyl polyoxyethylene polyoxypropylene ether (molecular weight 2000) into a reactor equipped with a stirrer and a thermometer , 20 parts of methacrylic acid, 50 parts of decyl acrylate, 10 parts of ethyl acrylate, 3 parts of azobisisoheptanonitrile, after heating up to 80°C for 15 hours, add 1 part of 2-tert-butylhydroquinone, 0.5 1 part of trioctylmethylammonium chloride, add 20 parts of glycidyl methacrylate, continue to react at 110°C for 5 hours, remove the solvent to obtain a water-based acrylate prepolymer; dissolve it in 200 parts of water, and Stir for 10min to obtain an aqueous acrylate prepolymer emulsion;

[0052] Preparation of UV-curable acrylate polymer aqueous emulsion: Take 300 parts of the above-mentioned aqueous a...

Embodiment 3

[0055] Embodiment 3: the preparation of UV photocurable acrylate polymer water emulsion for polypropylene film coating

[0056] Preparation of water-based acrylate prepolymer emulsion: by weight ratio, add 180 parts of xylene, 10 parts of allyl polyoxyethylene polyoxypropylene ether (molecular weight 3000), 10 parts of Methacrylic acid, 60 parts of isooctyl acrylate, 20 parts of propyl acrylate, 2.5 parts of azobisisovaleronitrile, after heating up to 78°C for 12 hours, add 0.8 parts of p-hydroxyanisole, 0.4 parts of trioctyl bromide Ammonium, add 10 parts of glycidyl acrylate, continue to react at 105°C for 4.5 hours, remove the solvent to obtain a water-based acrylate prepolymer; dissolve it in 200 parts of water, and stir at a high speed for 10 minutes at room temperature to obtain a water-based acrylate prepolymer Lotion;

[0057] Preparation of UV-curable acrylate polymer aqueous emulsion: Take 300 parts of the above-prepared aqueous acrylate prepolymer emulsion, add 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com