Device for preparing silicon carbide fiber by direct current heating CVD method and preparation method of silicon carbide fiber

A silicon carbide fiber, direct current technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of uneven structure of SiC coating, gas impurities cannot be quickly discharged, and coating cannot be realized. and other problems to achieve the effect of ensuring performance, reducing temperature difference, and facilitating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

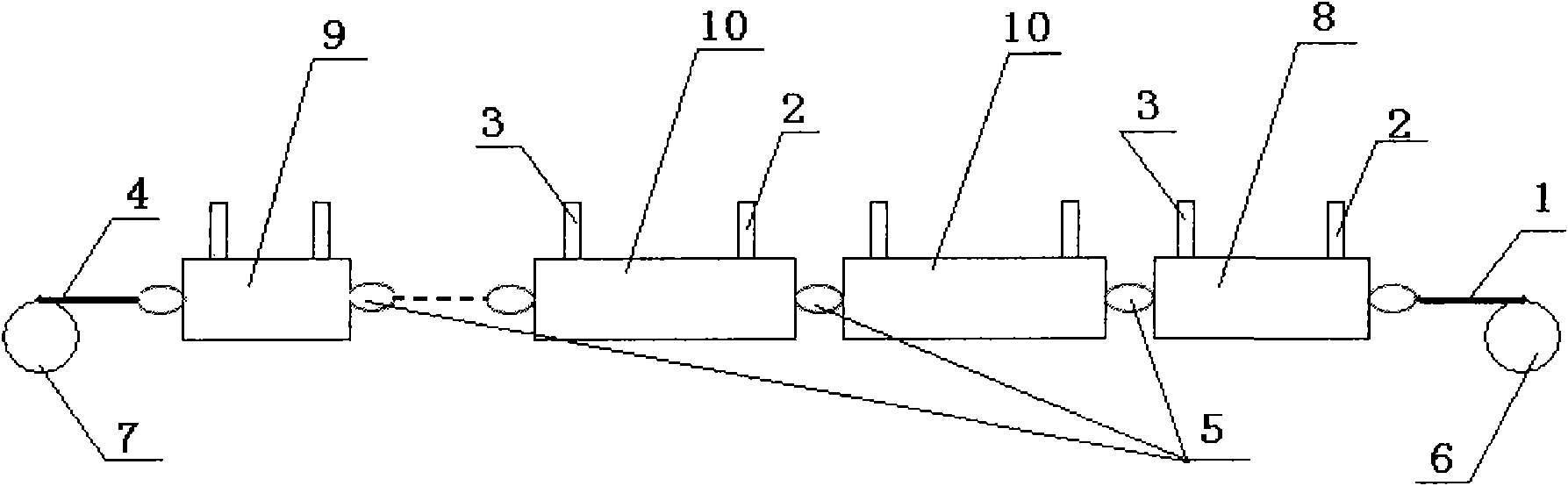

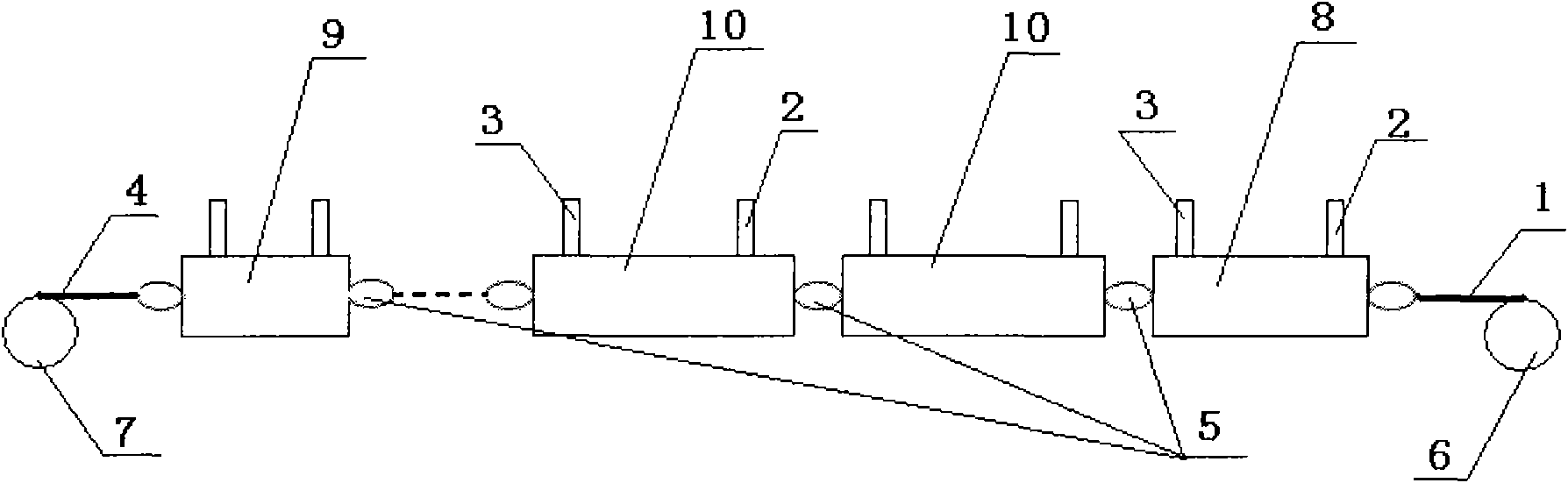

[0061] A preparation setup employing two deposition chambers.

[0062] The tungsten core passes through the pretreatment chamber, and hydrogen is passed through the pretreatment chamber, and the two ends of the tungsten core are heated by direct current. The internal temperature of the pretreatment chamber is 1200°C, the length of the pretreatment chamber is 15mm, and the gas flow rate is 0.3L / min;

[0063] Pass the mixed gas of methyltrichlorosilane, methyldichlorosilane and hydrogen into the first deposition chamber according to a certain ratio, the volume ratio of the mixed gas is: hydrogen accounts for 20% of the total volume, and methyltrichlorosilane accounts for the total volume 40%, the balance is methyldichlorosilane, the mixed gas flow rate is 3L / min; the length of the first deposition chamber is 25mm, and the temperature of the first deposition chamber is 1400°C; the temperature difference between the front and rear of the deposition chamber is 30°C, and the preparat...

Embodiment 2

[0067] A preparation setup employing two deposition chambers.

[0068] The tungsten core passes through the pretreatment chamber, and hydrogen is passed through the pretreatment chamber, and the two ends of the tungsten core are heated by direct current. The temperature inside the pretreatment chamber is 1150 ° C, the length of the pretreatment chamber is 20 mm, and the gas flow rate is 0.4 L / min;

[0069] Pass the mixed gas of methyltrichlorosilane, methyldichlorosilane and hydrogen into the first deposition chamber according to a certain ratio, the volume ratio of the mixed gas is: hydrogen accounts for 30% of the total volume, and methyltrichlorosilane accounts for the total volume 30%, the balance is methyldichlorosilane, the mixed gas flow rate is 3.5L / min; the length of the first deposition chamber is 15mm, and the temperature of the first deposition chamber is 1300°C; the temperature difference between the front and rear ends of the deposition chamber is 20°C, and the pr...

Embodiment 3

[0073] A preparation setup employing two deposition chambers.

[0074] The carbon core passes through the pretreatment chamber, and hydrogen is passed through the pretreatment chamber, and the two ends of the carbon core are heated by direct current. The internal temperature of the pretreatment chamber is 1100°C, the length of the pretreatment chamber is 20mm, and the gas flow rate is 0.5L / min;

[0075] Pass the mixed gas of methyltrichlorosilane, methyldichlorosilane and hydrogen into the first deposition chamber according to a certain ratio, the volume ratio of the mixed gas is: hydrogen accounts for 25% of the total volume, and methyltrichlorosilane accounts for the total volume 25%, the balance is methyldichlorosilane, the mixed gas flow rate is 4.5L / min; the length of the first deposition chamber is 30mm, and the temperature of the first deposition chamber is 1250°C; the temperature difference between the front and rear ends of the deposition chamber is 40°C, and the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com