Surface-modified rubber plug and preparation method thereof

A technology for surface modification and rubber stoppers, applied in the field of surface modified rubber stoppers and their preparation, can solve the problems of unreliable sealing performance and safety performance of rubber stoppers, difficult film covering process of rubber stoppers, increased production costs, etc., to achieve easy Implementation, obvious effect, effect of reducing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

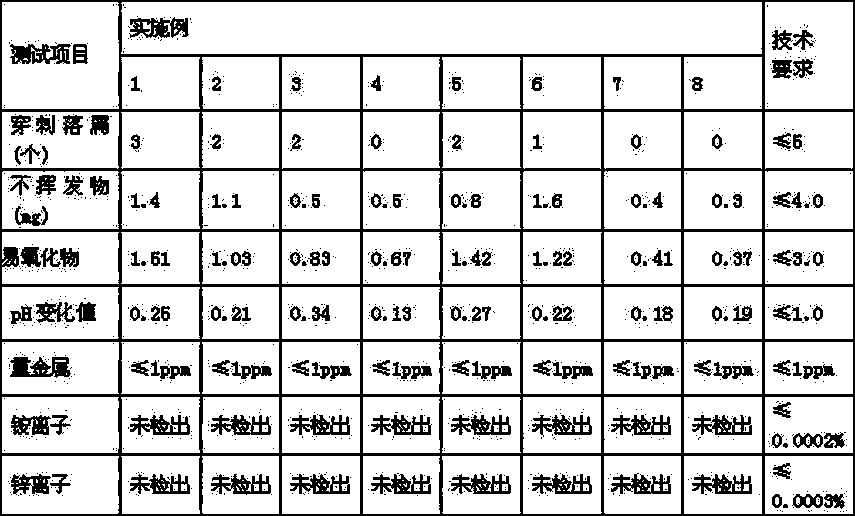

Examples

preparation example Construction

[0030] The preparation method of the medical rubber stopper modified by PVDC of the present invention comprises the following steps:

[0031] Step 1: Provide the rubber plug body, which can be a molded or commercially available medical rubber plug;

[0032] Step 2, cleaning and drying the rubber stopper body;

[0033] Step 3, putting the cleaned and dried rubber stopper into a closed corona stirring tank for corona treatment for 20-120 minutes;

[0034] Step 4, put the corona-treated rubber plug into the PVDC emulsion at 60-120°C under nitrogen, and stir for 6-24 hours;

[0035] Step 5, the rubber stopper is taken out from the emulsion, washed with water, ethanol, and chloroform in sequence, and dried to obtain a surface-modified medical rubber stopper.

Embodiment 1

[0037] Clean and dry the commercially available halobutyl rubber stoppers, put them into a corona stirred tank, adjust the current intensity to 9A, treat with air corona plasma under normal pressure for 20 minutes, turn off the corona, and remove the rubber stoppers within two hours. Transfer to a PVDC emulsion at 70°C under nitrogen, stir for 6 hours, take the rubber plug out of the emulsion, wash and dry with water, ethanol, and chloroform in sequence to obtain a surface-modified rubber plug.

Embodiment 2

[0039] Use natural rubber stopper, current intensity 12A, normal pressure nitrogen plasma treatment for 60 minutes, 80°C PVDC emulsion, stirring for 16 hours, the rest is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com