Preparation method of modified aluminum oxide and PMMA mixed slurry coated diaphragm

A technology of mixing slurry and alumina, applied in the direction of structural parts, electrical components, battery pack parts, etc., can solve the problems of easy agglomeration, difficult to disperse, large particle interaction force, etc., to suppress agglomeration and prevent black spots. , the effect of reducing moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

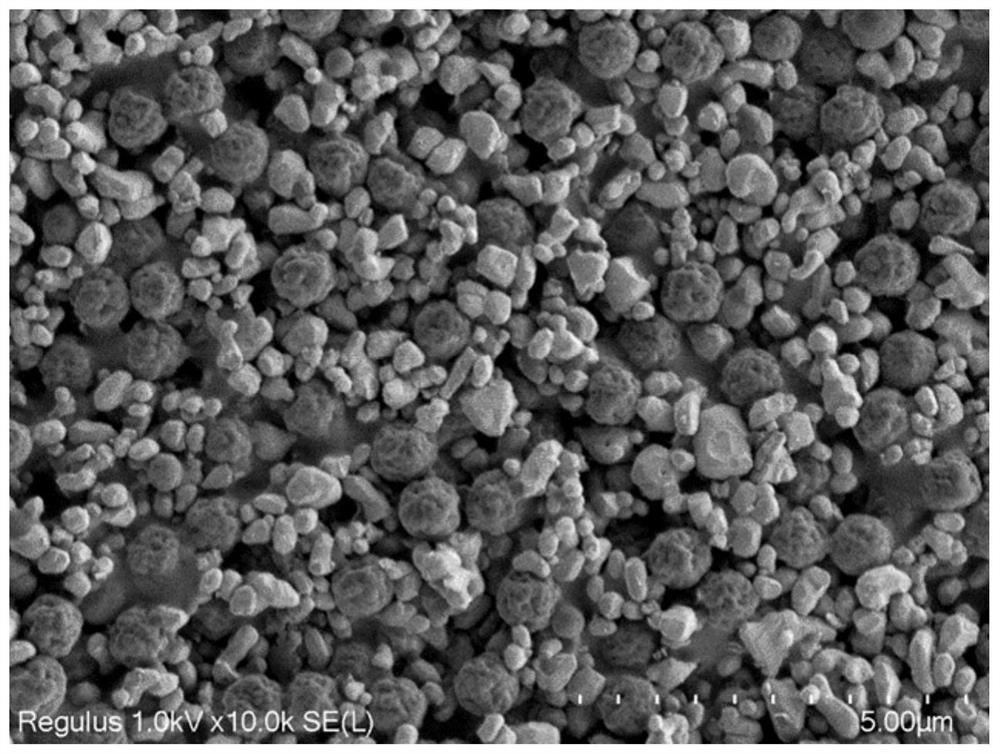

Image

Examples

Embodiment 1

[0048] A method for preparing a modified alumina and PMMA mixed slurry coating diaphragm, the specific steps are as follows,

[0049] S1. Preparation of modified alumina:

[0050] (1) Take 8.5 parts of silane coupling agent KH-570, add 83 parts of 95% ethanol solution, stir, add a particle size of 300 nm, and a specific surface of 4 m 2 1.8 parts / g of alumina powder, heated and stirred at a temperature of 45°C, stirred at 500 r / min for 1 h to obtain a mixed solution;

[0051] (2) performing suction filtration on the mixed solution, and drying the modified alumina solid at 55° C. for 25 hours to obtain modified alumina powder particles;

[0052] S3. Preparation of slurry:

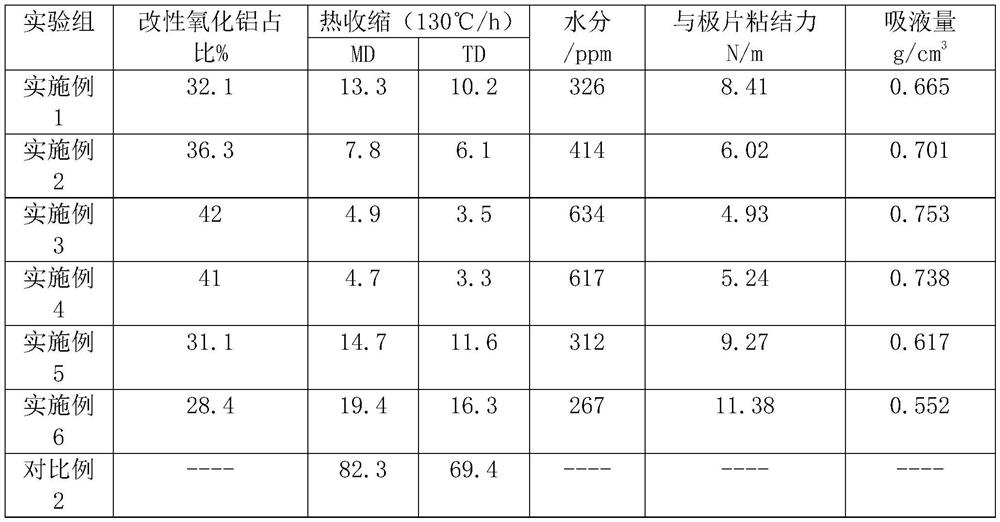

[0053] Take 24.3 parts of deionized water, add 32.1 parts of modified alumina powder, stir at 600r / min for 40min, add 8.76 parts of sodium carboxymethyl cellulose, stir at 650r / min for 60min, add polymethyl methacrylate and butylbenzene 34.6 parts of latex, stirred at 500r / min for 40min, added 0.24 part o...

Embodiment 2

[0057] A method for preparing a modified alumina and PMMA mixed slurry coating diaphragm, the specific steps are as follows,

[0058] S1. Preparation of modified alumina:

[0059] (1) Take 9.8 parts of silane coupling agent KH-570, add 88 parts of 95% ethanol solution, stir, add a particle size of 600 nm, and a specific surface of 5 m 2 2.1 parts / g of alumina powder, heated and stirred at a temperature of 50°C and stirred at 600r / min for 1.5h to obtain a mixed solution;

[0060] (2) performing suction filtration on the mixed solution, and drying the modified alumina solid at 61° C. for 27 hours to obtain modified alumina powder particles;

[0061] S3. Preparation of slurry:

[0062] Take 24.3 parts of deionized water, add 36.3 parts of modified alumina powder, stir at 600r / min for 40min, add 8.76 parts of sodium carboxymethyl cellulose, stir at 650r / min for 60min, add polymethyl methacrylate and butylbenzene 30.4 parts of latex, stirred at 500r / min for 40min, added 0.24 par...

Embodiment 3

[0066] A method for preparing a modified alumina and PMMA mixed slurry coating diaphragm, the specific steps are as follows,

[0067] S1. Preparation of modified alumina:

[0068] (1) Take 11.5 parts of silane coupling agent KH-570, add 90 parts of 95% ethanol solution, stir, add a particle size of 900 nm, and a specific surface of 7 m 2 / g alumina powder 2.4 parts, heating and stirring, temperature 60 ° C, stirring at 700 r / min for 2 h, to obtain a mixed solution;

[0069] (2) performing suction filtration on the mixed solution, and drying the modified alumina solid at 65° C. for 30 hours to obtain modified alumina powder particles;

[0070] S3. Preparation of slurry:

[0071] Take 24.3 parts of deionized water, add 42 parts of modified alumina powder, stir at 600r / min for 40min, add 8.76 parts of sodium carboxymethylcellulose, stir at 650r / min for 60min, add polymethyl methacrylate and butylbenzene 24.7 parts of latex, stirred at 450r / min for 40min, added 0.24 part of wet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com