Anti-corrosion coating process in oil casing pipe

A technology of oil casing and internal anti-corrosion, which is applied in the direction of coating, manufacturing tools, metal processing equipment, etc., can solve the problems of high error rate, low efficiency, complicated process, etc., and achieve the goal of ensuring friction strength and reducing excessive friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment provides an anti-corrosion coating process inside the casing

[0070] The raw material used in this process is 244.48mm outer diameter, 11.99mm wall thickness, plain end casing of N80Q steel grade.

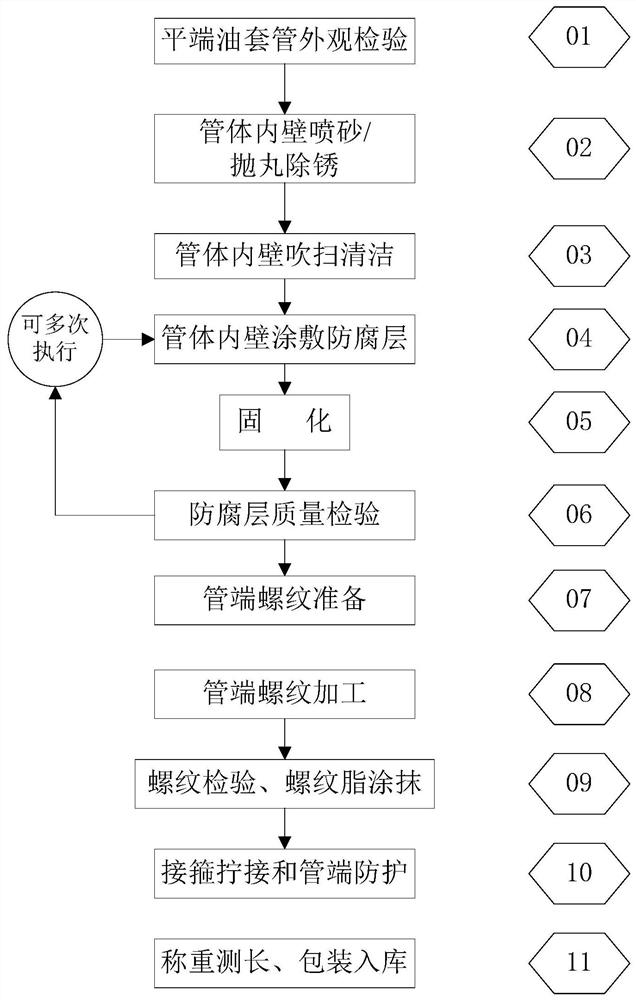

[0071] The anti-corrosion coating process in the casing includes:

[0072] (1) The flat-end casing entering the coating factory can enter the coating production line after the appearance inspection of the tube body, including damage inspection, dirt inspection, and foreign matter inspection; avoid damage such as bump damage, pit damage, scratch damage, and bending damage The casing with oil stains on the inner wall can enter the coating production line after manual cleaning; the casing with embedded oxide scale on the inner wall can only enter the coating production line after cleaning the embedded oxide scale.

[0073] (2) Derust the inner wall of the casing entering the coating production line, and use steel brush power tools to ensure that the quality le...

Embodiment 2

[0087] This embodiment provides a high temperature resistant type anti-CO 2 Anti-corrosion coating process inside the anti-corrosion layer

[0088] The raw material used in this process is 73.02mm outer diameter, 5.51mm wall thickness, L80-1 steel grade flat-end oil pipe, and the operating temperature of the oil pipe reaches 180°C.

[0089] The anti-corrosion coating process in the oil pipe includes:

[0090] (1) The flat-end tubing entering the coating factory can enter the coating production line after the appearance inspection of the pipe body, including damage inspection, dirt inspection, and foreign matter inspection; avoid bump damage, pit damage, scratch damage, bending damage, etc. The oil pipe enters the coating production line; for the oil pipe with oil stains on the inner wall, it can enter the coating production line after manual cleaning; for the oil pipe with embedded scale on the inner wall, it can enter the coating production line after the embedded scale is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com