Patents

Literature

52results about How to "Lower total production cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing chlorogenic acid

InactiveCN1435406ALow costLower total production costCarboxylic acid esters separation/purificationReflux extractionOrganic solvent

A process for preparing the chlorogenic acid used as medicinal component includes reflux extraction of dried arctium leaves in organic solvent at pH=2-3 several times for 3 hr, filtering per time, collecting filtrate, vacuum concentrating, recovering alcohol to obtain raw extract, chromatography by polyamide column, eluting with water and methanol, concentrating and refining. Its advantage is low cost.

Owner:SHANDONG UNIV

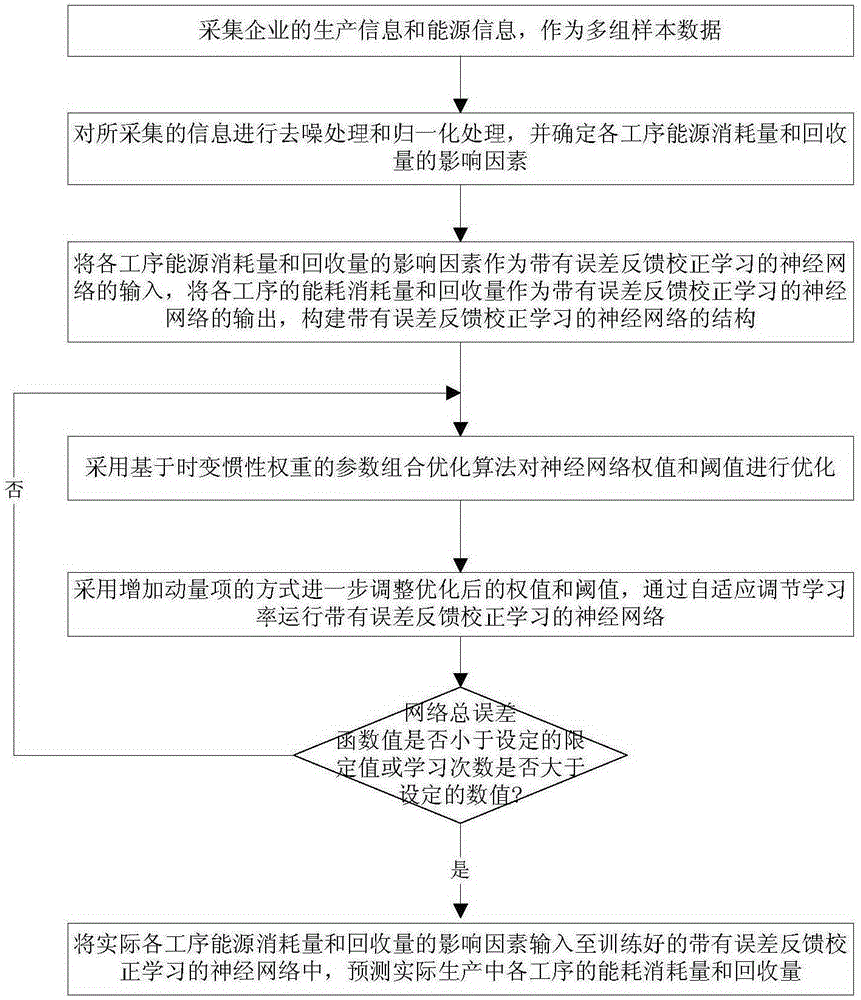

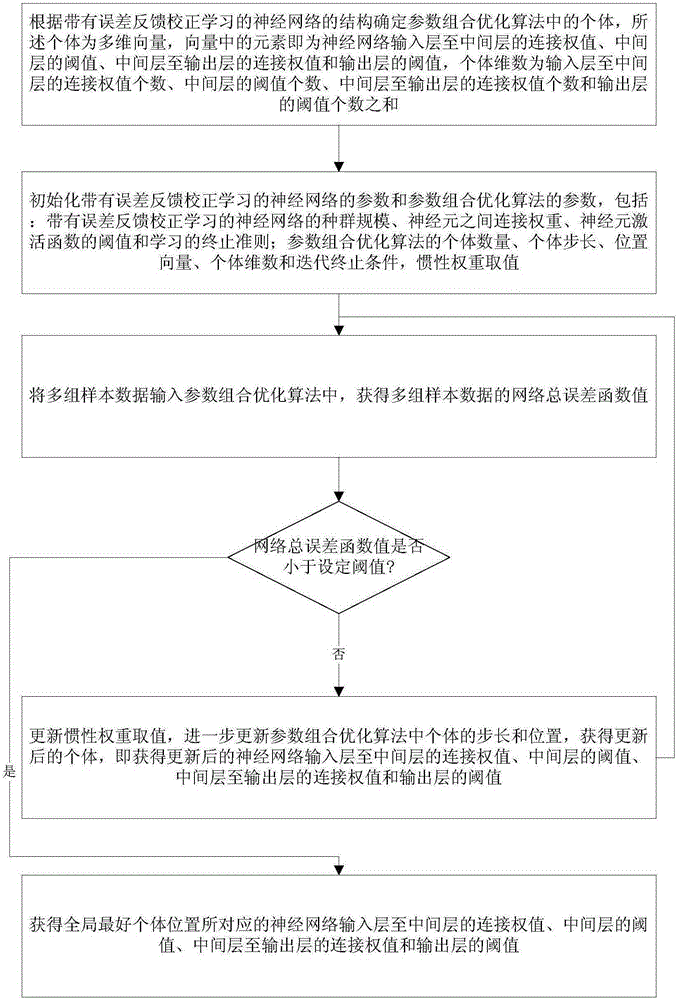

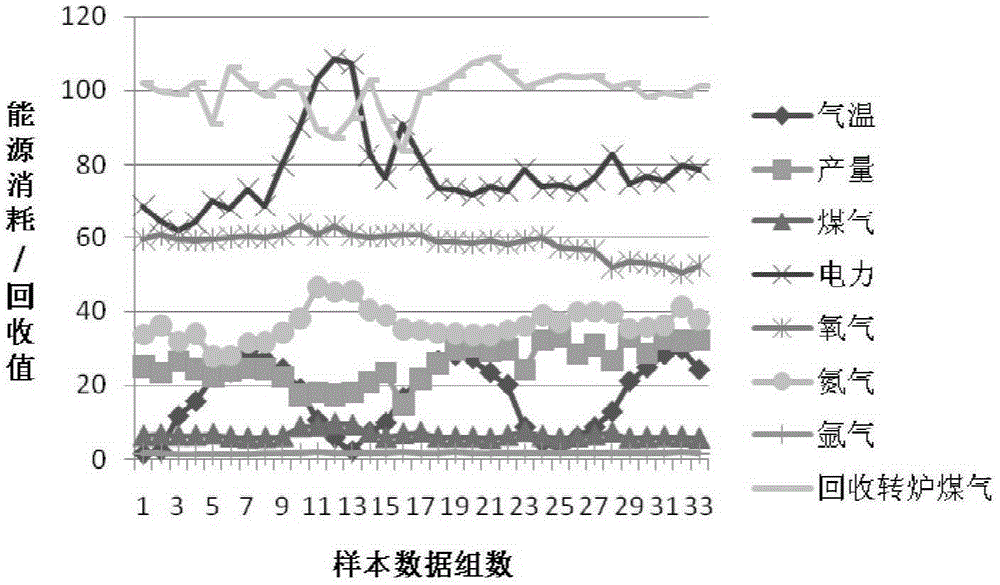

Energy consumption prediction method for improving energy utilization rate of iron and steel enterprise

ActiveCN105204333AIncrease training speedImprove efficiencyAdaptive controlPredictive methodsPower usage effectiveness

The invention, which belongs to the field of the information technology, relates to an energy consumption prediction method for improving an energy utilization rate of an iron and steel enterprise. A neural network algorithm with error feedback correction learning is used for carrying out prediction. In order to solve a problem of slow convergence speed of the traditional learning method, a momentum is added into an adjusting formula of a weight value and a threshold value, thereby accelerating a training speed of a network. With an adaptive adjusting learning rate, a learning rate of training at an error curved surface flat area is increased; and a learning rate is reduced at a drastic error changing area. On the basis of time-varying-weight-based parameter combination optimization method, distribution of an initial weight value and an initial threshold value is optimized, and good searching space is localized in solution space to avoid a local minimal point. According to the energy consumption prediction method, characteristics of energy consumption of all procedures are taken into consideration; the energy utilization rate is improved; and the energy costs are reduced and thus total production cost is lowered.

Owner:NORTHEASTERN UNIV

Burdock inulin and its preparing method

Burdock synanthrin and its preparation method. the matter is extracted from root of burdock, white or weak yellow amorphous loose solid powder, freely soluble in water, slightly sweet, stable thermally. The left of optical rotation in water is -29.8í

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

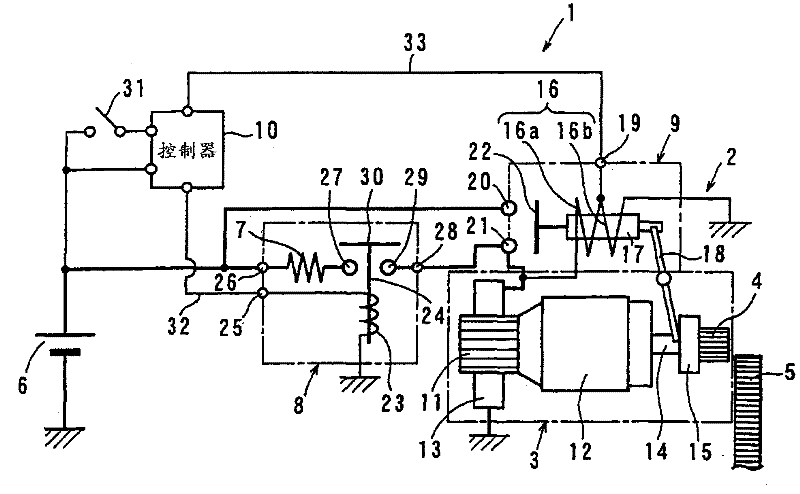

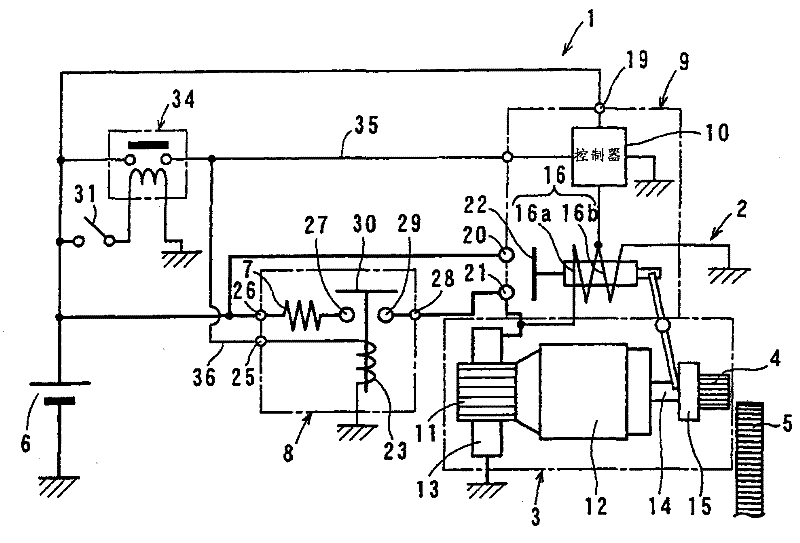

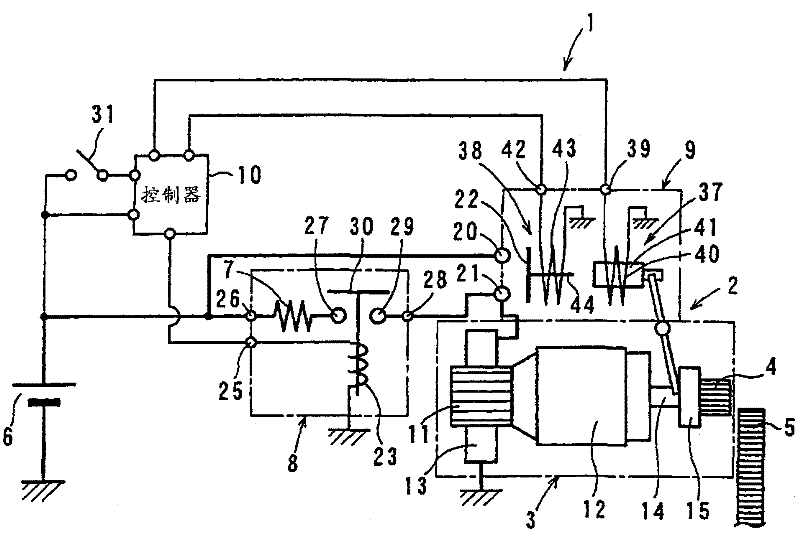

Engine starting system with high-and low-speed modes of motor operation

ActiveCN102192068AGuaranteed stabilityLower total production costEngine controllersElectric motor startersLow speedElectrical battery

The invention relates to an engine starting system with high-and low-speed modes of motor operation. An engine starting apparatus includes a first and a second power supply path extending from a battery to an electric motor to start an engine. An electromagnetic switch has main contacts disposed in the first power supply path. A resistor is disposed in the second power supply path. A motor relay has relay contacts disposed in series with the resistor. A controller delays the time when the main contacts are closed to apply a full voltage of the battery to the motor until a given time lag has elapsed after the relay contacts are closed to supply electric current to the electric motor through the resistor. Specifically, when it is required to apply the full voltage to the motor to run the motor at a rated speed, the current does not pass through the relay contacts, thus resulting in no voltage drop, which ensures the stability in starting the engine.

Owner:DENSO CORP

Preparation method of large-particle crystal type high-bulk-density calcium 2-hydroxy-4-(methylthio)butyrate

The invention belongs to the field of the chemical industry, and relates to a preparation method of large-particle crystal type high-bulk-density calcium 2-hydroxy-4-(methylthio)butyrate. The preparation method of the large-particle crystal type high-bulk-density calcium 2-hydroxy-4-(methylthio)butyrate comprises the following steps that 2-hydroxy-4-(methylthio)butyric acid, a calcium compound and a crystallizing agent are arranged in an aqueous medium, the pH is adjusted to be 5-7, the temperature is 60-80DEG C, stirring and full reactions are carried out, cooling crystallization is carried out to obtain calcium 2-hydroxy-4-(methylthio)butyrate crystals, separation is carried out to obtain crystals and coarse product mother liquid, and the crystals serve as calcium 2-hydroxy-4-(methylthio)butyrate coarse products. The calcium compound is one or more of calcium salt, calcium oxide and calcium hydroxide, and the use amount of the crystallizing agent is 50ppm-3000ppm of the mass of the 2-hydroxy-4-(methylthio)butyric acid. Materials produced through the preparation method of the large-particle crystal type high-bulk-density calcium 2-hydroxy-4-(methylthio)butyrate are high in purity, dehydration is easy, drying is rapid, crystal particles obtained after drying are large, good in mobility and large in bulk density, the amount of dust is low, glossiness is high, and the materials are more applicable to fodder.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Method for preparing asparagus rutin

InactiveCN1546506ALower total production costThe extraction process is perfect and feasibleSugar derivativesSugar derivatives preparationAlcoholElution

The invention relates to a method for preparing asparagus rutin which comprises, cleaning the asparagus spears, drying and disintegrating, alcohols leaching, elution with adsorption resin, proceeding vacuum enriching recovery, obtaining the concentration liquid, removing protein and filtering the filter residue, obtaining the filter liquor, watering to steam the trichloroacetic acid dissolvent, filtering, cooling to evolute the rutin.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

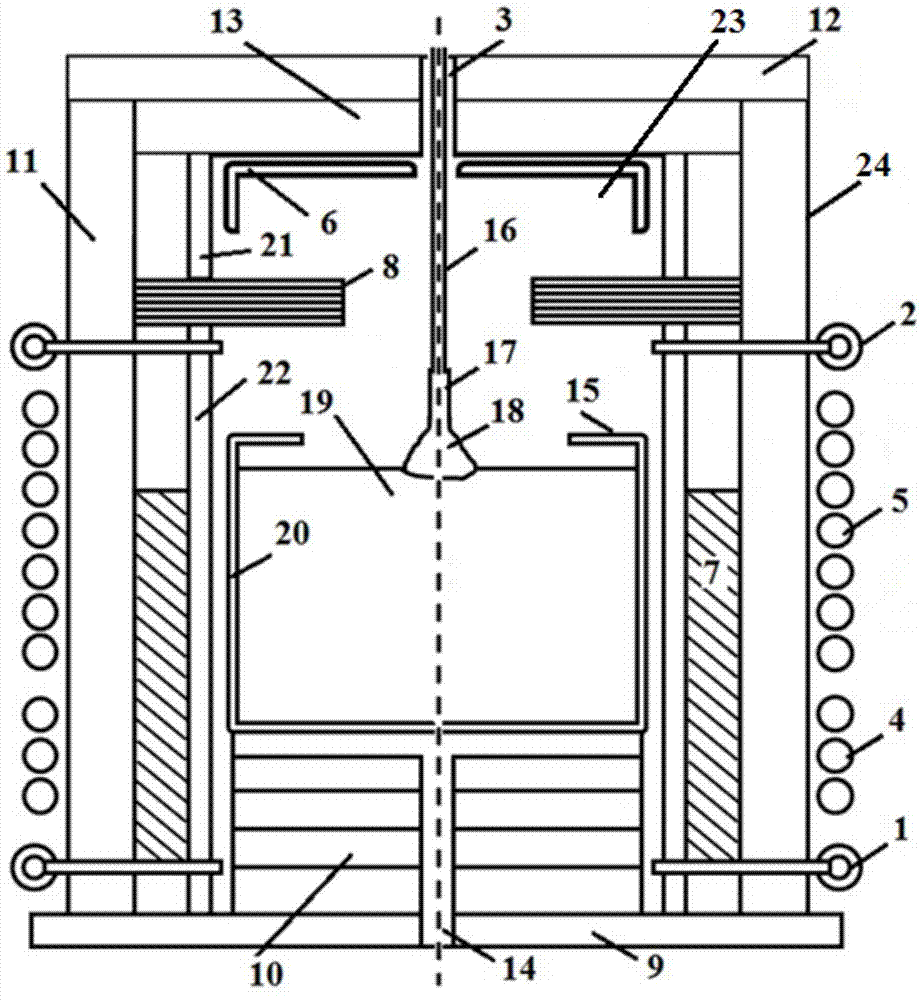

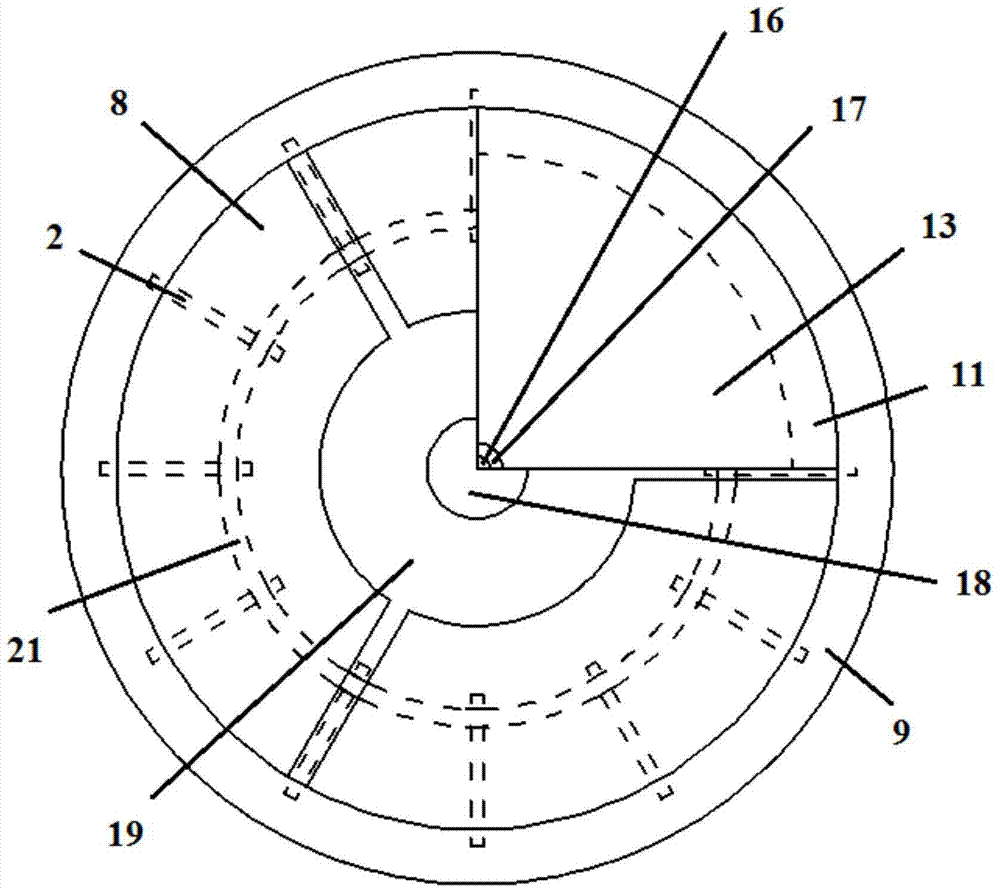

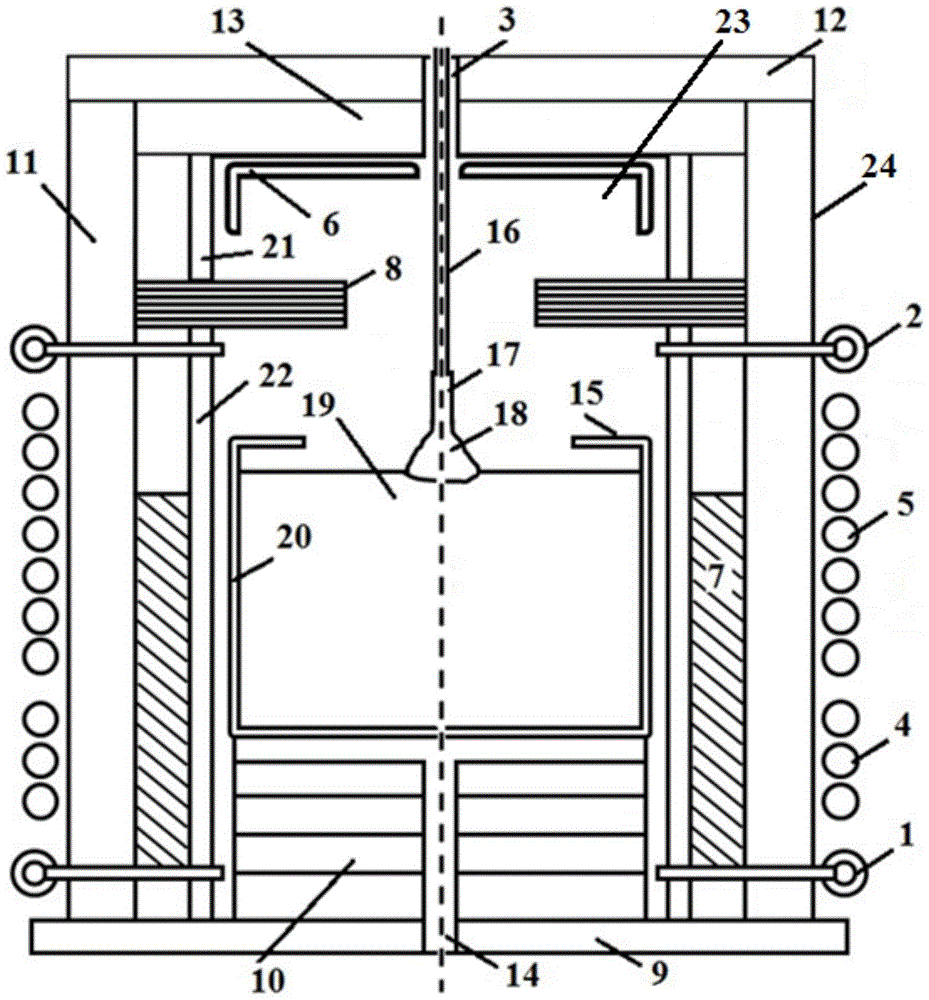

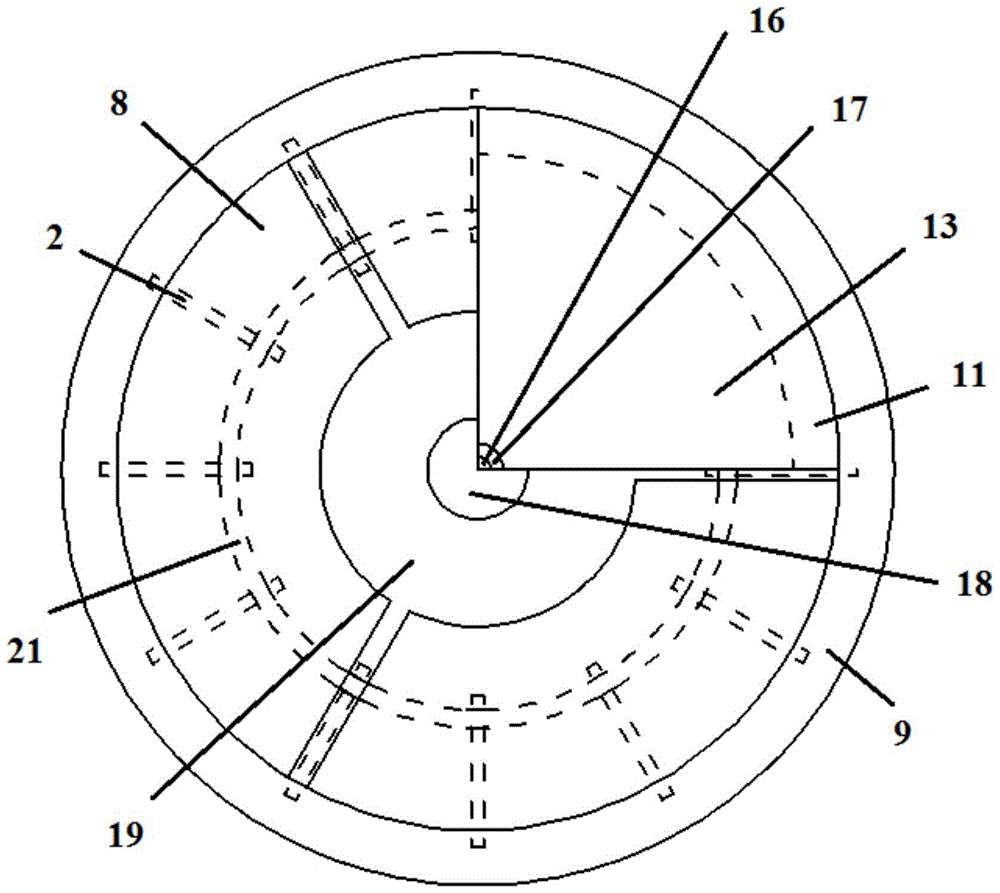

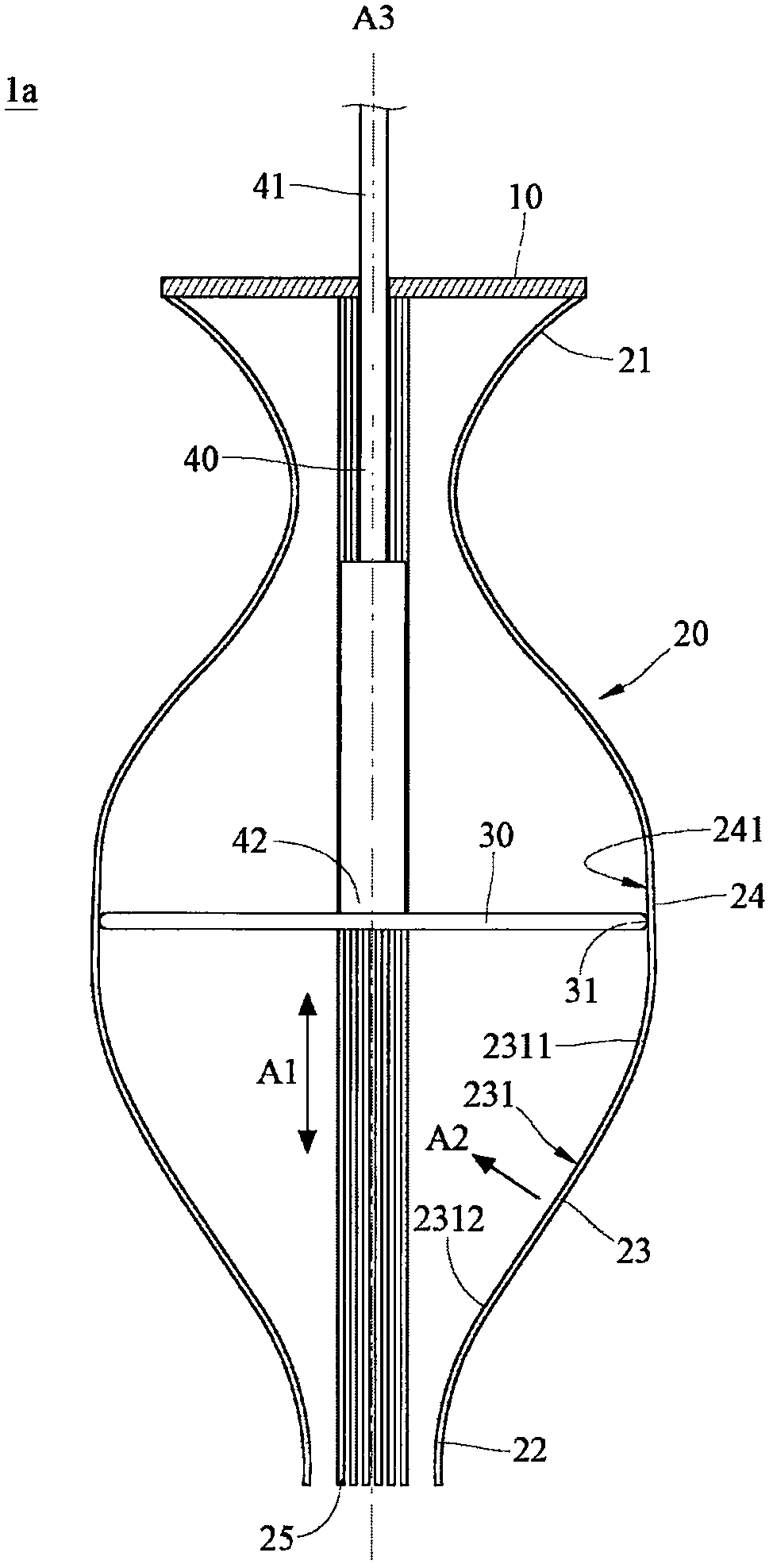

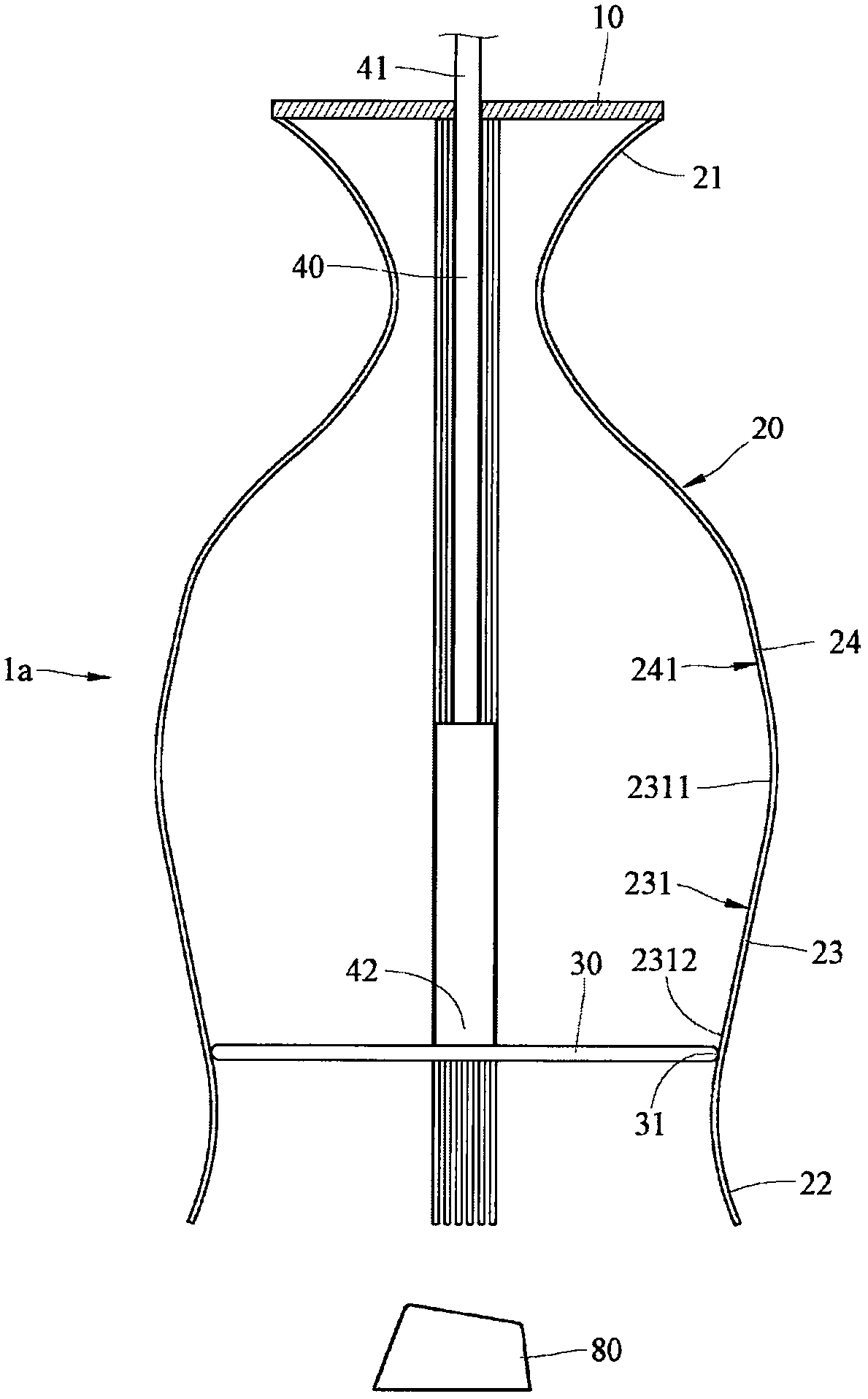

Thermal field coordination control Czochralski crystal growth furnace

ActiveCN104514032AIncrease temperatureShorten the chemical timeBy pulling from meltElectrical resistance and conductanceThermal isolation

The invention discloses a thermal field coordination control Czochralski crystal growth furnace. The crystal growth furnace comprises a thermal isolation outer housing and a growth chamber arranged in the thermal isolation outer housing; a crucible is arranged in the growth chamber; main electromagnetic induction coils used for heating the crucible are arranged at the exterior of the thermal isolation outer housing; auxiliary electromagnetic induction coils are arranged under the main electromagnetic induction coils; an interval is formed between the main electromagnetic induction coils and the auxiliary electromagnetic induction coils; a plurality of bottom air inlet pipes and a plurality of middle air inlet pipes extend into the thermal isolation outer housing in parallel; an airflow outlet is formed in the top of the thermal isolation outer housing, and is taken as a seed rod moving passage; telescopic insulation boards used for weakening heat transfer by radiation and top auxiliary resistance heating devices used for adjusting partial temperature of the growth chamber are arranged in the thermal isolation outer housing; the length, extending into the growth chamber, of the telescopic insulation boards can be adjusted. The crystal growth furnace can effectively restrain crystal defects, improves crystal quality, remarkably improves crystal finished product ratio, and reduces production cost.

Owner:HUAZHONG UNIV OF SCI & TECH

Treating process of water-rich aluminium hydroxide sludge

InactiveCN1398800AEasy to operateSave freezer spaceSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludge cakeFluidized bed

The present invention is a treatment method for water-rich aluminium hydroxide sludge. Water-rich aluminium hydroxide sludge is rolled into sheet, and then it is frozen in a multiple-process and multiple-section belt conveyer type freezer with freezing temperature of minus 30 to minus 10 deg.C for 30-60 min; it is dewatered in a normal temperature-water thawing tank, low-vacuum filtered or squeezed to obtain wet sludge cake; and it is dried in a multiple-partition hot-carrier fluidized bed with industrial waste gas at 70-90 deg.C for 30-60 min to obtain the dry aluminium hydroxide sludge product. The present invention has the features of easy operation, low power consumption, low cost and no pollution.

Owner:FUZHOU UNIV

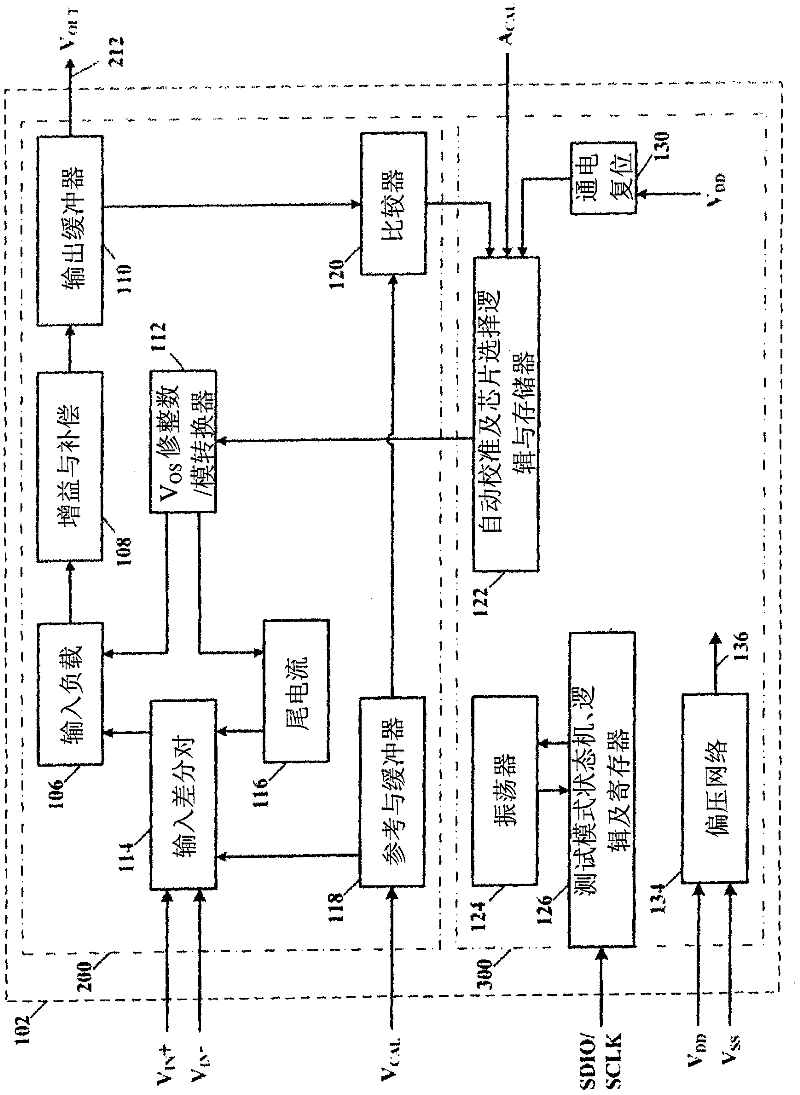

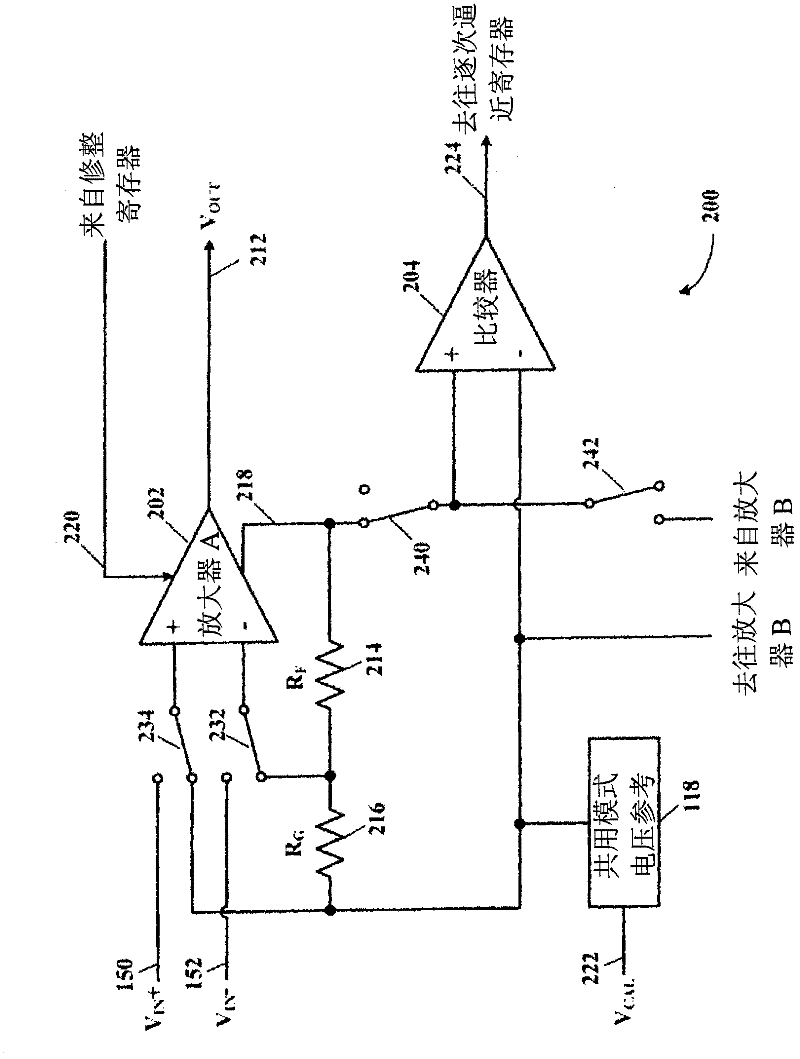

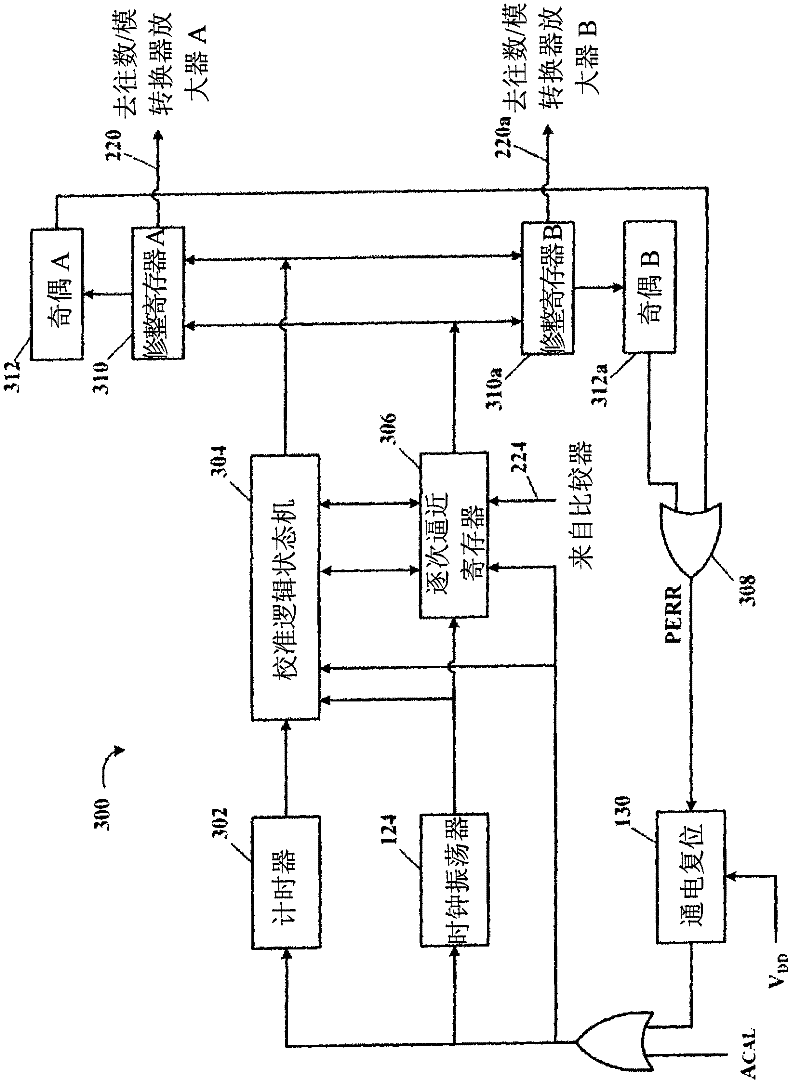

Self auto-calibration of analog circuits in a mixed signal integrated circuit device

ActiveCN102187571ALower total production costRF amplifierAnalogue-digital convertersEngineeringVoltage reference

Auto-calibration of the analog circuits occurs when requested by a user and / or the occurrence of an event(s). The user may invoke an auto-calibration on demand through an auto-calibration (ACAL ) input to the mixed-signal integrated circuit. An external voltage calibration (VCAL ) input may be used for auto-calibration of the mixed-signal integrated circuit to a user-supplied common-mode voltage reference. Auto-calibration of the mixed- signal integrated circuit may also be initiated upon the occurrence of any one or more of the following events: 1 ) detection of auto-calibration data corruption, e.g., parity checking of auto-calibration data values digitally stored in the mixed-signal integrated circuit; 2) an internal timer that causes a calibration request after a programmable timeout period, 3) change in the internal integrated circuit die temperature as determined by a temperature sensor, and 4) a change in the power supply and / or internal supply voltage(s).

Owner:MICROCHIP TECH INC

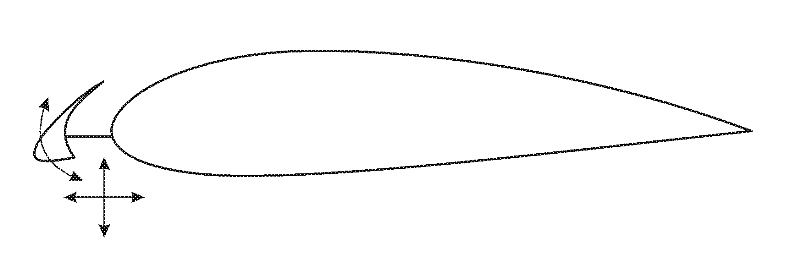

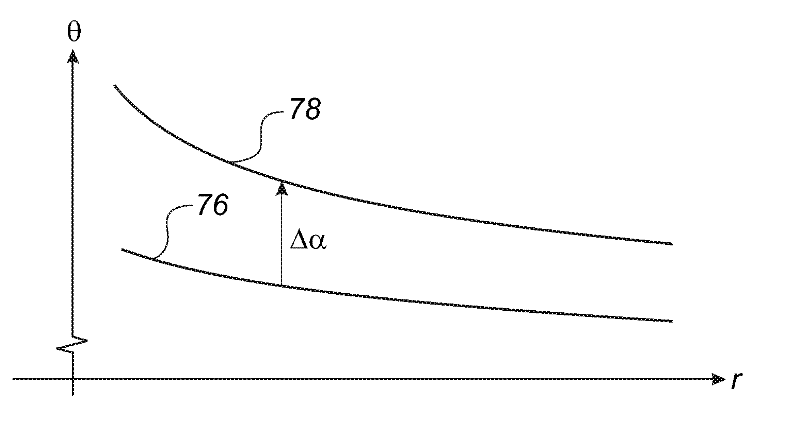

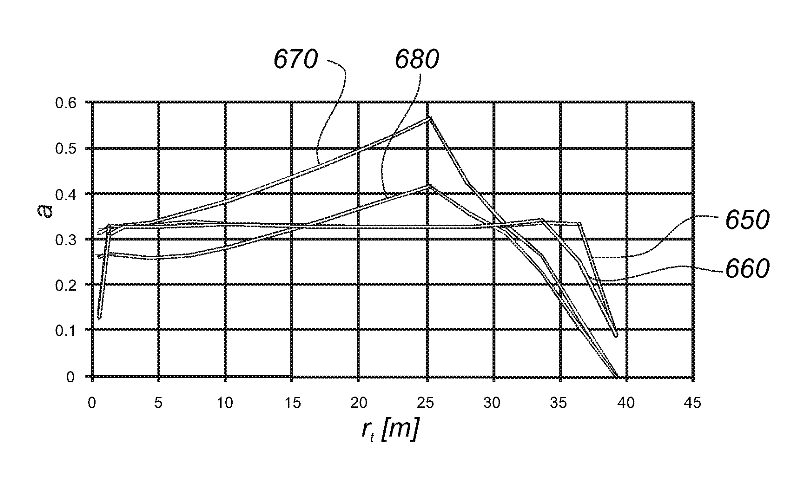

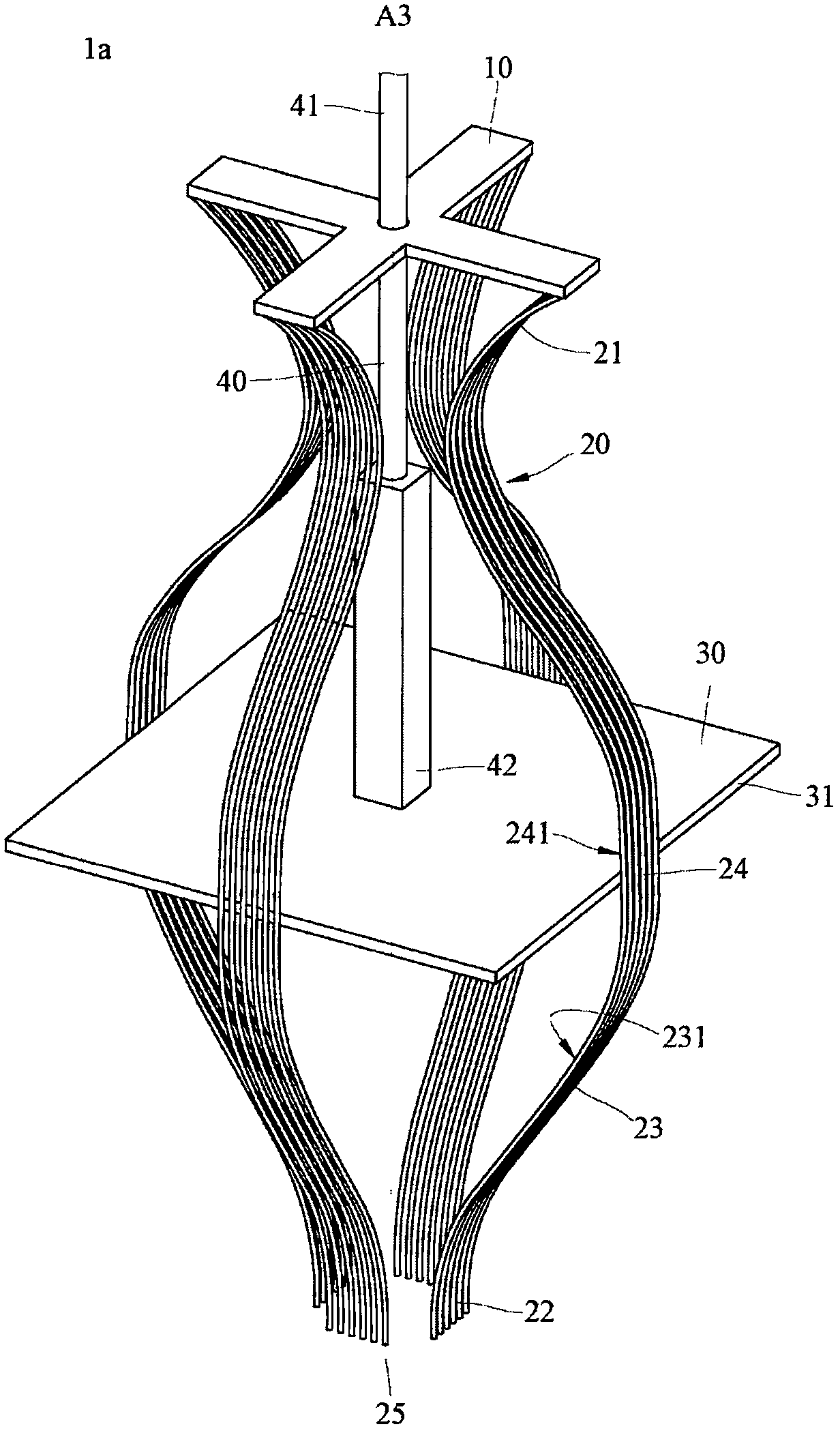

Wind turbine blade with base part having inherent non-ideal twist

ActiveCN102459878AEasy to shapeAvoid hyperbolic blade profilesMachines/enginesEngine componentsLeading edgeTurbine blade

A blade for a rotor of a wind turbine having a substantially horizontal rotor shaft is described. The rotor comprises a hub, from which the blade extends substantially in a radial direction when mounted to the hub. The blade comprises a profiled contour comprising a pressure side and a suction side as well as a leading edge and a trailing edge with a chord extending between the leading edge and the trailing edge, the profiled contour generating a lift when being impacted by an incident airflow, the profiled contour in the radial direction being divided into a root region with a substantially circular or elliptical profile closest to the hub, an airfoil region with a lift generating profile furthest away from the hub, and preferably a transition region between the root region and the airfoil region, the transition region having a profile gradually changing in the radial direction from the circular or elliptical profile of the root region to the lift generating profile of the airfoil region, wherein the airfoil region comprises at least a first longitudinal segment extending along at least 20% of a longitudinal extent of the airfoil region, the first longitudinal segment comprising a first base part having a leading edge and a trailing edge with a chord extending between the leading edge and the trailing edge. The first base part has an inherent non-ideal twist, such as no twist, or a reduced twist compared to a target blade twist, so that an axial induction factor of the first base part without flow altering devices at a design point deviates from a target axial induction factor. The first longitudinal segment is provided with a number of first flow altering devices arranged so as to adjust the aerodynamic properties of the first longitudinal segment to substantially meet the target axial induction factor at the design point.

Owner:LM GLASSFIBER

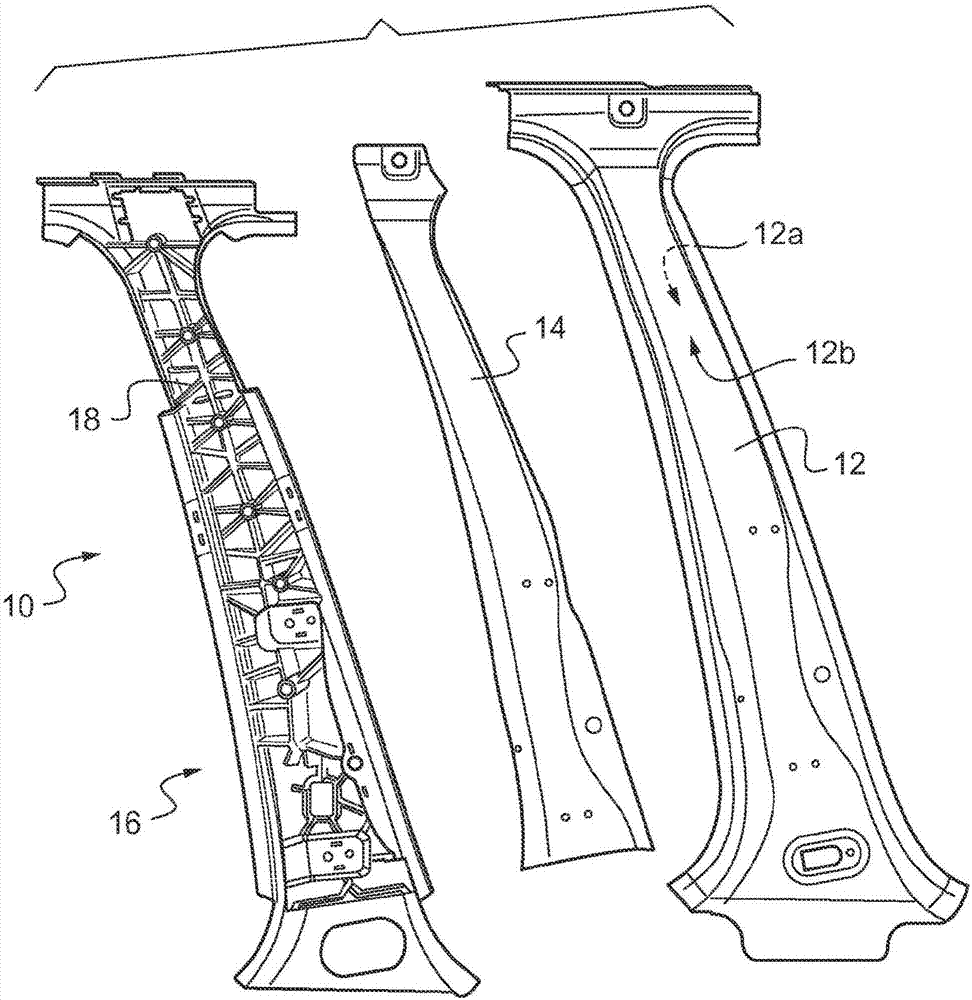

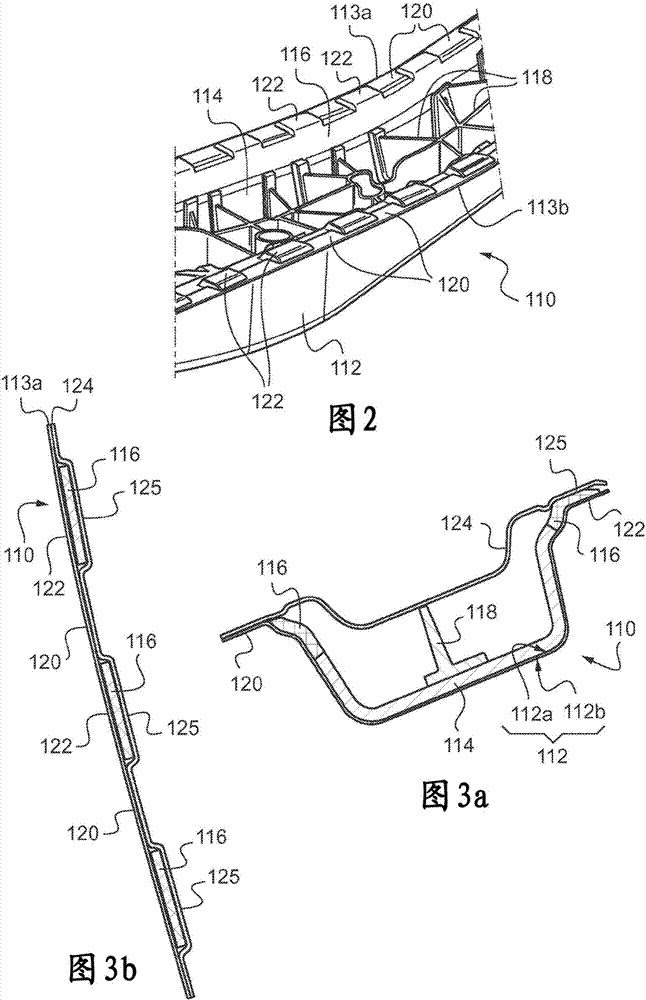

Method for producing a hybrid-structure part of a motor vehicle and corresponding hybrid-structure part

ActiveCN107107486AHigh strengthReduce manufacturing costSuperstructure subunitsDomestic articlesMetallic materialsMetal

The invention concerns a method for producing a hybrid-structure part of a motor vehicle, comprising shaping of a sheet of metallic material, the provision of a sheet of composite material, application of a layer of connecting material on a face of said metallic material sheet or on a face of said composite material sheet, the shaping of a hybrid element by shaping said composite material sheet to the shape of said metallic material sheet and joining the composite material sheet to the metallic material sheet by means of said connecting material layer, and the production of rigidification elements by overmoulding using a polymer material.

Owner:RENAULT SA +1

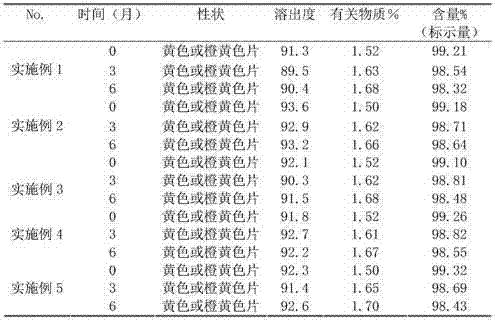

Folic acid pharmaceutical composition for preventing administration

InactiveCN104116743AReduce drying stepsReduced granulation processOrganic active ingredientsNervous disorderMedicineEnergy consumption

The invention relates to a folic acid pharmaceutical composition for preventing administration, and a preparation method thereof. A preparation of the composition adopts a dry granulation process, so that the manufacturing process is simplified, the energy consumption and the total production cost can be reduced, the output per unit time, the product quality and the like are improved, and the stability of the medicine storage period and the clinical safe medication are kept.

Owner:YANTAI ZHONGZHOU PHARMA CO LTD

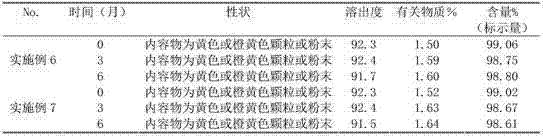

Anti-corrosion coating process in oil casing pipe

ActiveCN112439678AReduce excessive frictionGuaranteed friction strengthThread cutting machinesHollow article cleaningMachine partsMachining process

The invention provides an anti-corrosion coating process in an oil casing pipe. The process comprises the following steps that firstly, the inner wall of the flat-end oil casing is cleaned; secondly,anti-corrosion layer coating treatment and curing treatment are conducted on the inner wall of a flat-end oil casing pipe body; thirdly, threads at the pipe end of the oil casing pipe are machined; inthe thread machining process, the highest temperature of the inner wall of the thread machining part does not exceed 90% of the upper limit value of the temperature resistance of an anti-corrosion layer of the pipe body in terms of the celsius degree; cutting fluid used for thread machining does not damage the anti-corrosion layer coated on the inner wall of the oil casing pipe; and fourthly, theoil casing pipe is subjected to coupling tightening and pipe end protection, and the whole anti-corrosion coating process in the oil casing pipe is completed. The technological process is simple, thedefective product generation probability is low, and the anti-corrosion coating process can be well suitable for coating in the oil casing pipe of high-temperature-resistant anti-corrosion paint, andcoating in the low-end and conventional paint oil casing pipe for temporary storage and transportation is achieved at a low price.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

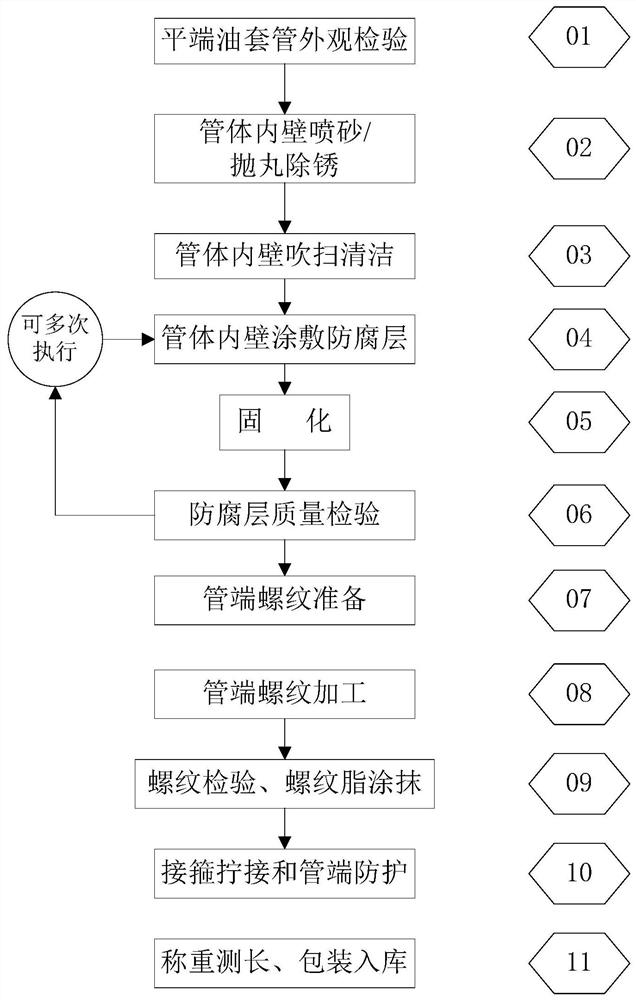

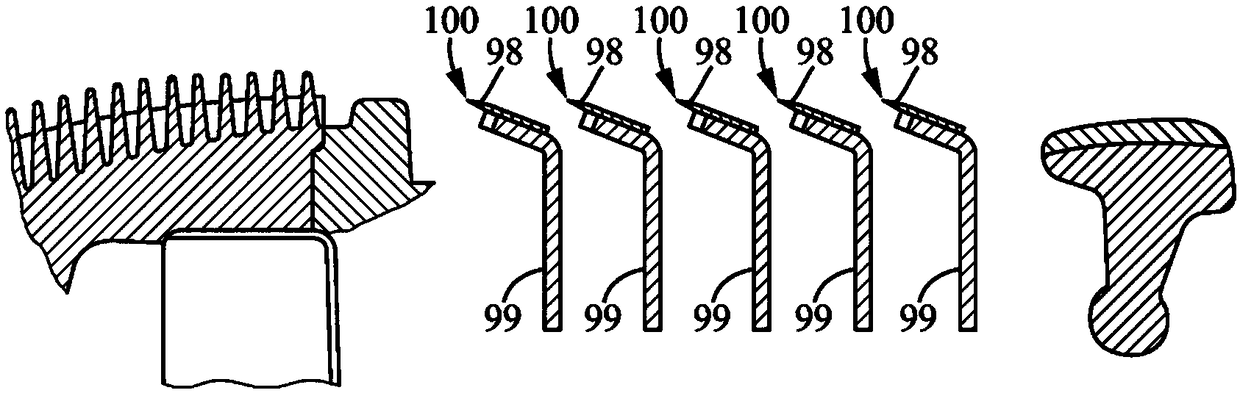

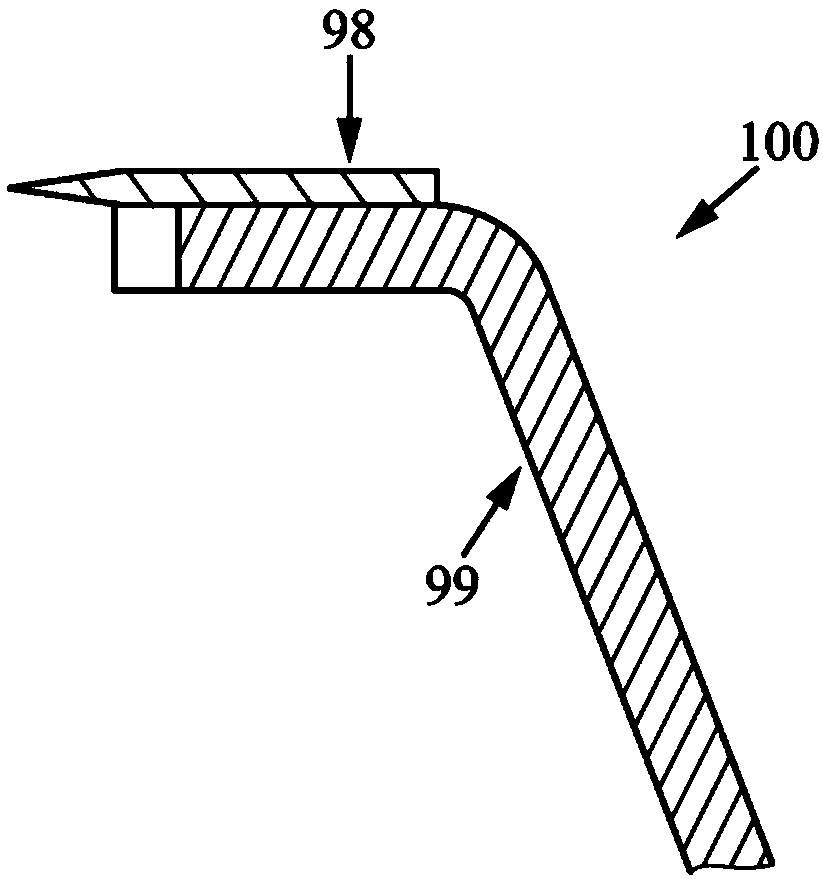

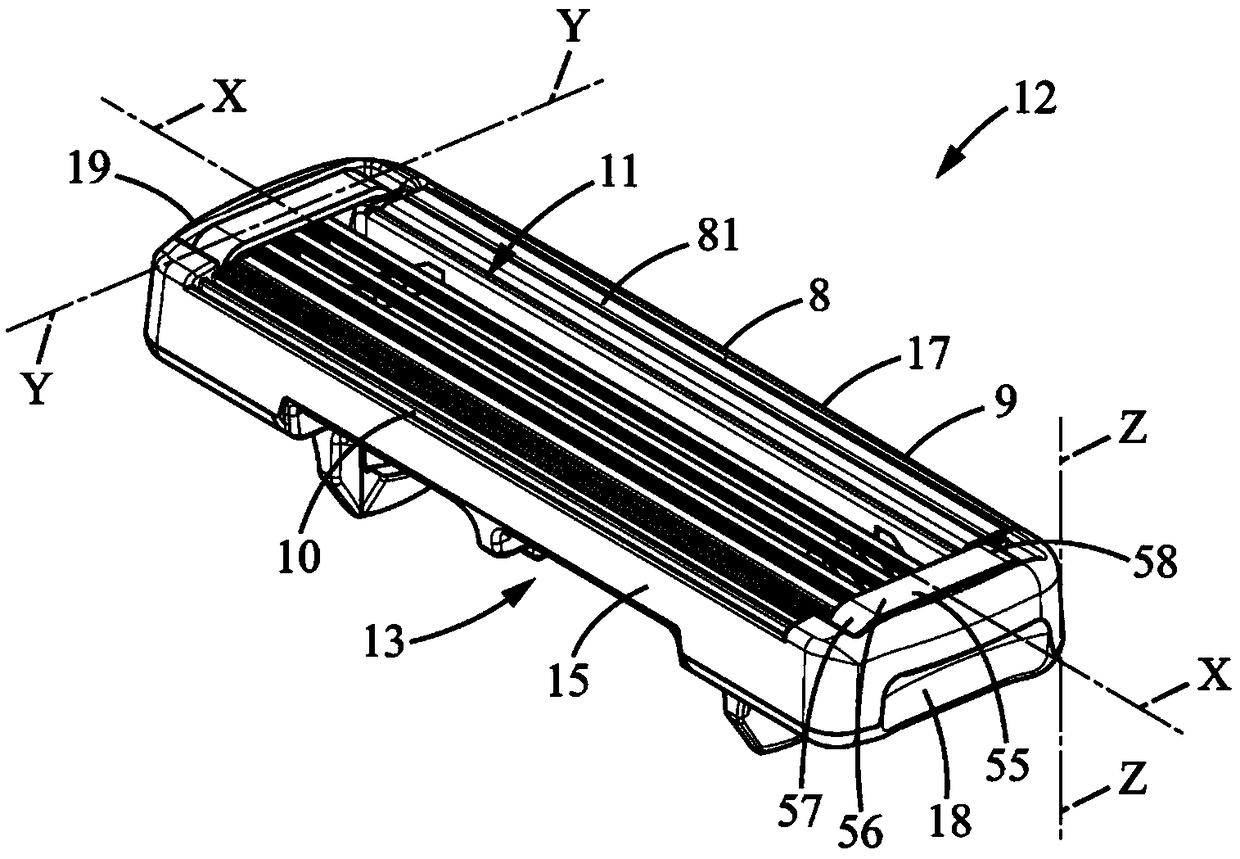

Razor system

PendingCN109153139AReduce aggressionFit tightlyMetal working apparatusStructural engineeringMechanical engineering

A cutting member (1) for a shaving cartridge that includes a flat cutting portion (2) that has a front cutting edge portion (21), a bent portion (32), and a base portion (33). Said bent portion is intermediate to said base portion and said flat cutting portion. At least said bent portion and said base portion are made out of one single piece of material. The said bent portion is arranged such thatit is adjacent to the front cutting portion. The proposed shape of the cutting member resembles a reverse L.

Owner:BIC VIOLEX SA

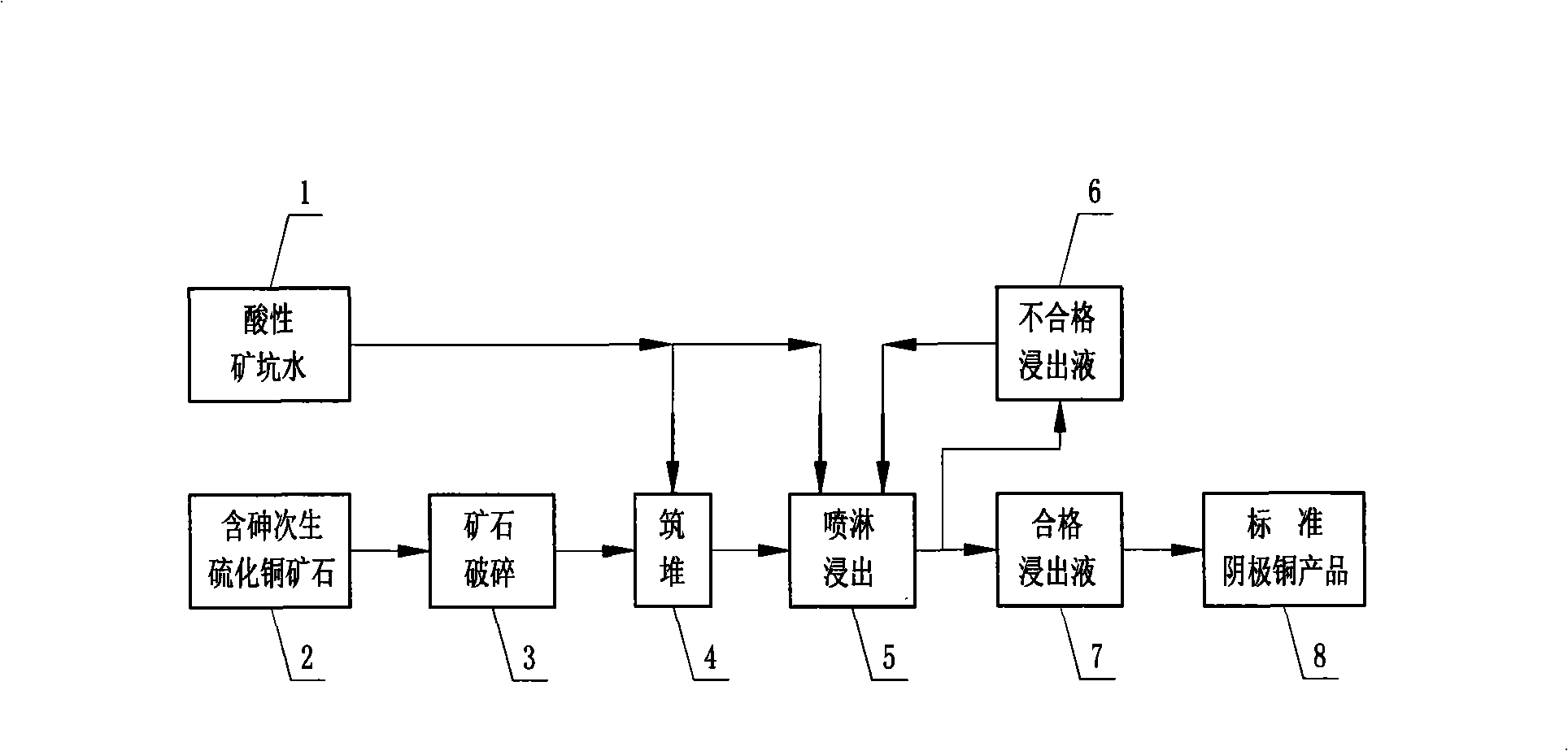

Earth's surface biological dump leaching process for secondary copper sulfide ore with higher arsenic content

InactiveCN101403037AConvenient sourceSimple and fast energy consumptionProcess efficiency improvementThiobacillus ferrooxidansDump leaching

The invention discloses a dump leaching technique of ground organism of secondary copper sulphide ore with high content of arsenic. The technique comprises the following steps: the secondary copper sulphide ore with high content of arsenic is crushed to 10 to 30mm, and acid mine water of mineral-leaching microorganism with thiobacillus ferrooxidans and thiobacillus thiooxidans is used for leaching the secondary copper sulphide ore with high content of arsenic; while most of the arsenic in the ore is still in leaching residue and a small part of the arsenic is in the leachate, faffinated and electrodeposition liquid; but closed cycle in the production has no effect on the extraction and electrodeposition and standard cathode copper product, thus avoiding the hazard of the arsenic to the environment. The technique has short process, little investment, low cost and energy consumption, no pollution and high rate of recovery, can process the copper ore with high content of arsenic which can not be processed by the traditional smelting technique, and also can process the secondary copper sulphide ore with high content of arsenic and similar secondary copper sulphide ore with high content of arsenic so as to expand the utilization range of resources.

Owner:CHINA NERIN ENG

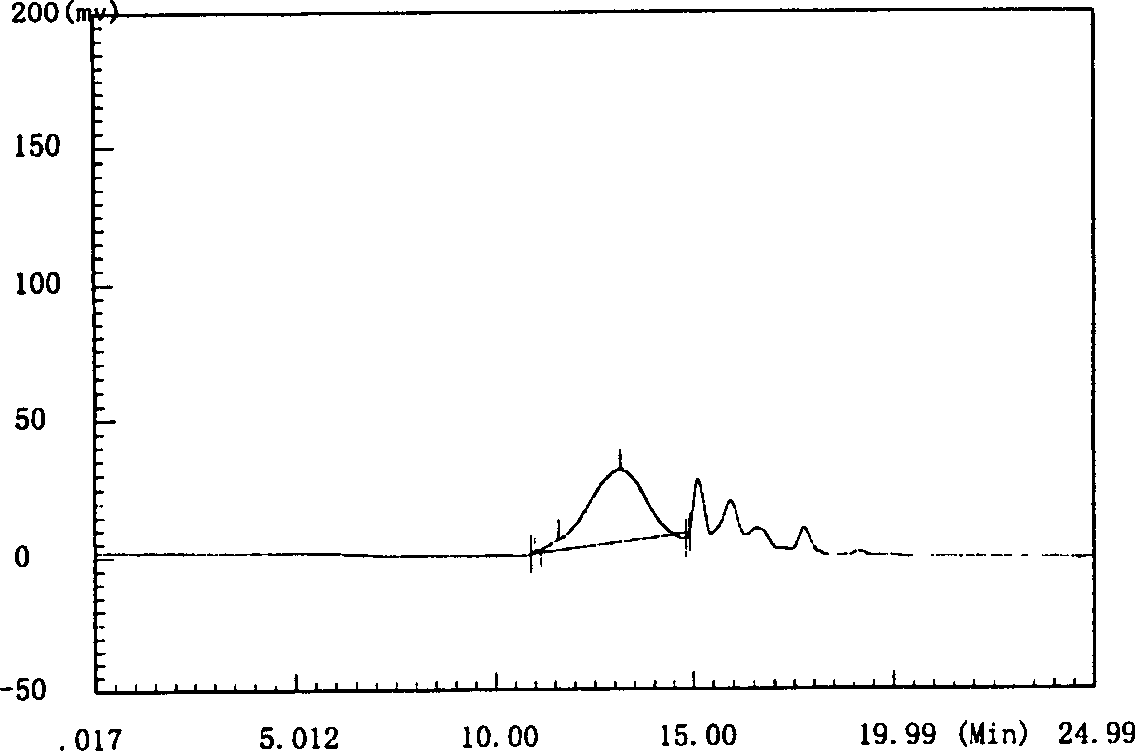

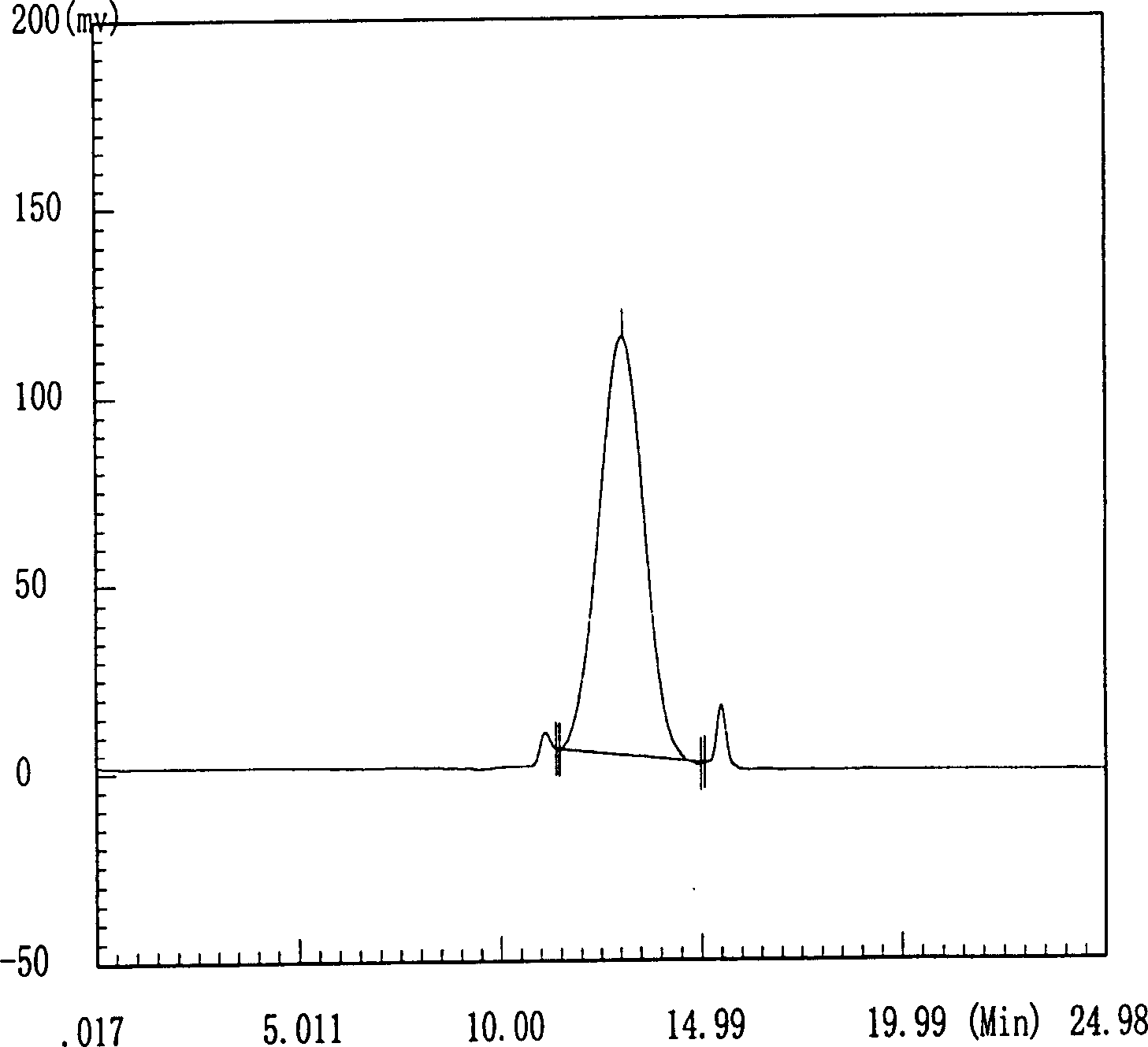

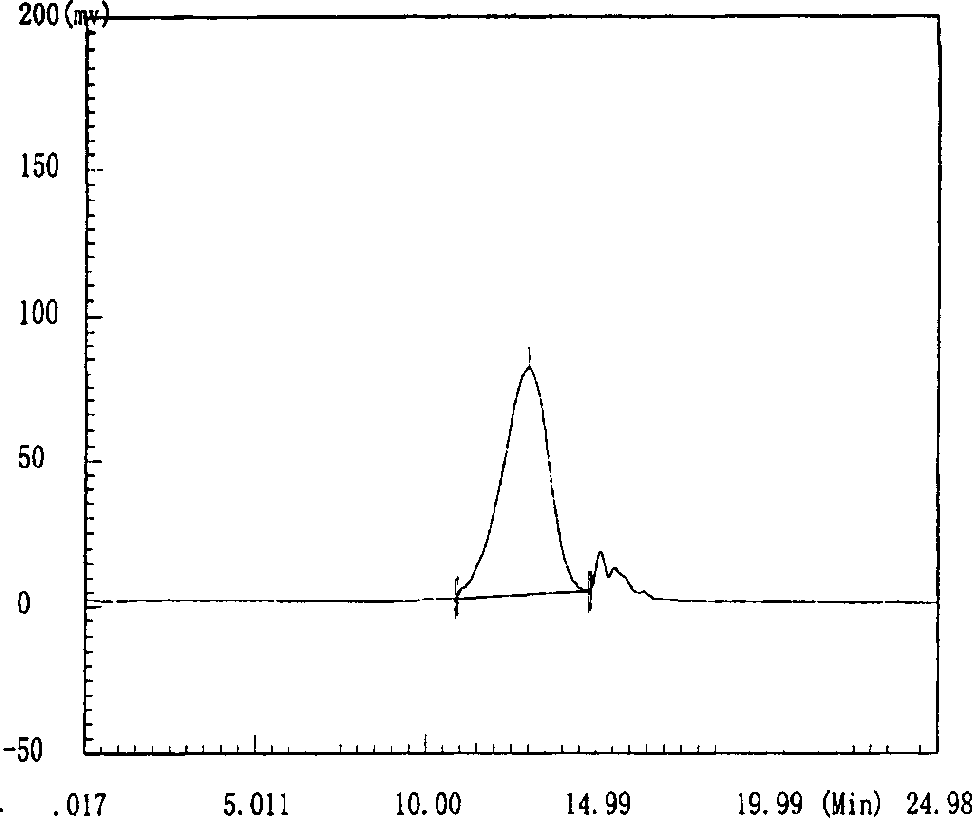

Burdock inulin and its preparing method

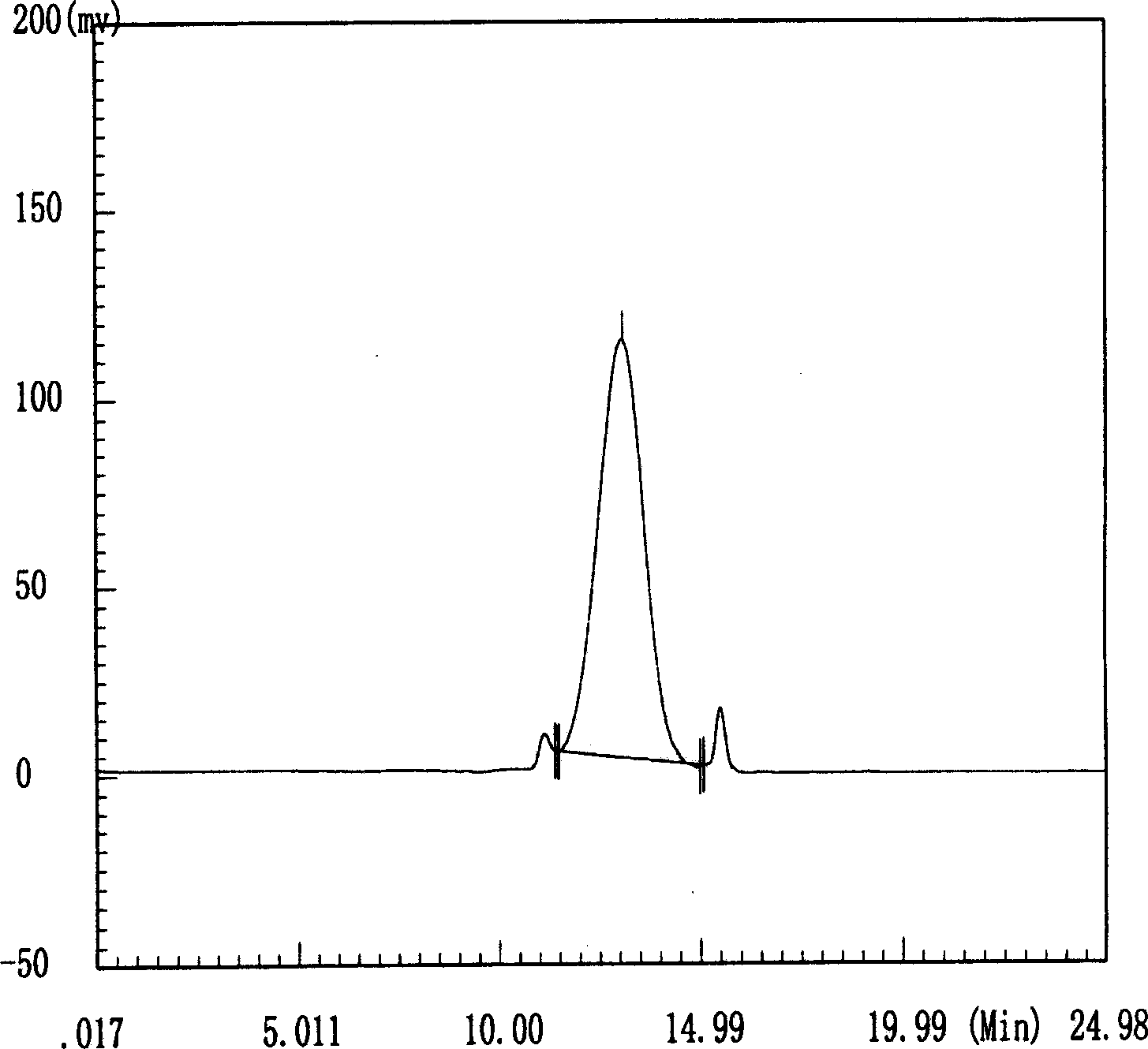

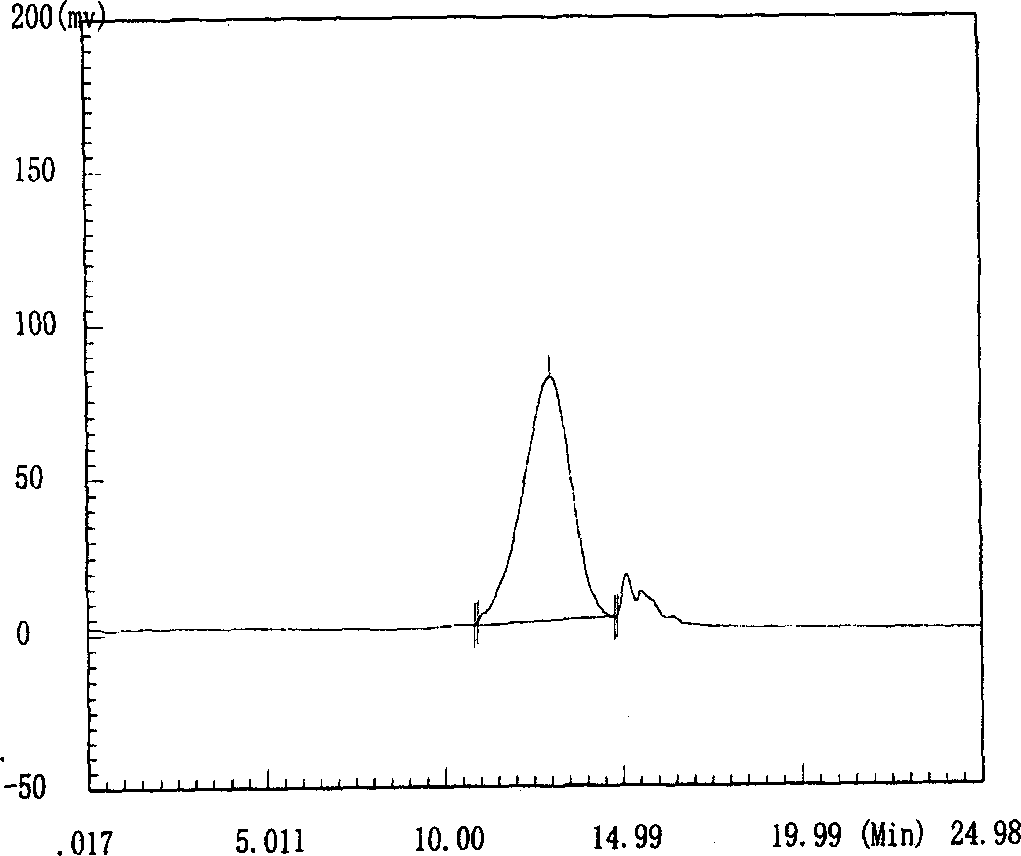

Burdock synanthrin and its preparation method. the matter is extracted from root of burdock, white or weak yellow amorphous loose solid powder, freely soluble in water, slightly sweet, stable thermally. The left of optical rotation in water is -29.8+ / -2 deg. the formula is D-fructose of furan, polymerizing with beta (2->1) glucosidicbond and forming low fructosan, the terminal of the molecular chain linked with a glucose by alpha(1 ->2) glucosidicbond; the simple formula is G-Fn, G is glucose, F is fructose, n is the degree of polymerization: 10-12, the average molecular weight is 1976-2230; after analyzing by an ultraviolet chromatography, an absorbing peak in 202nm. In the collecting pattern of glucose gel chromatography, there has a single symmetric peak, which means that, the synanthrin has a high purity and is a uniform component. The extraction rate of the invention is up to more than 85%.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

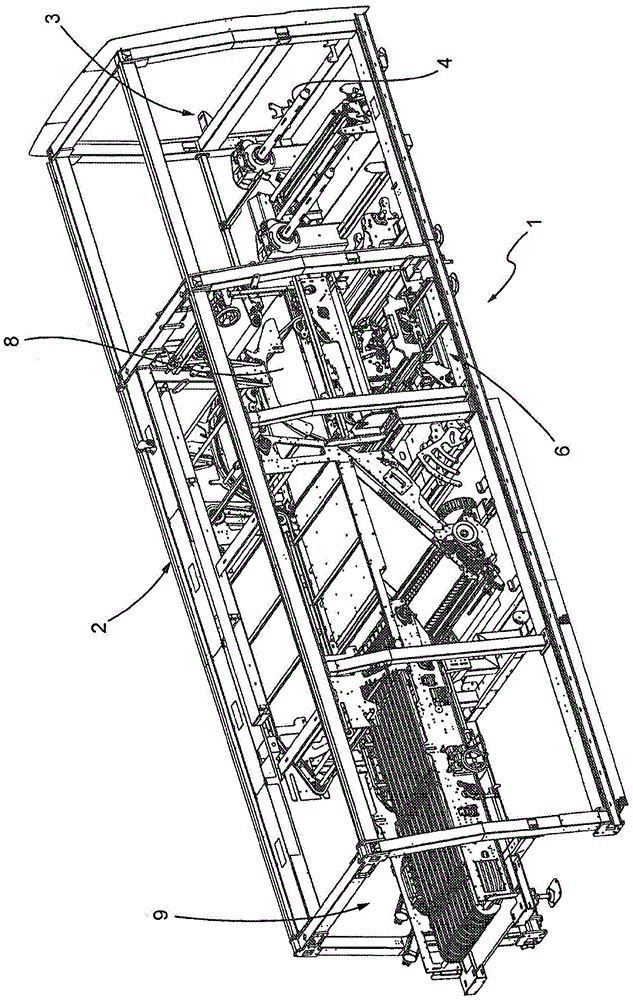

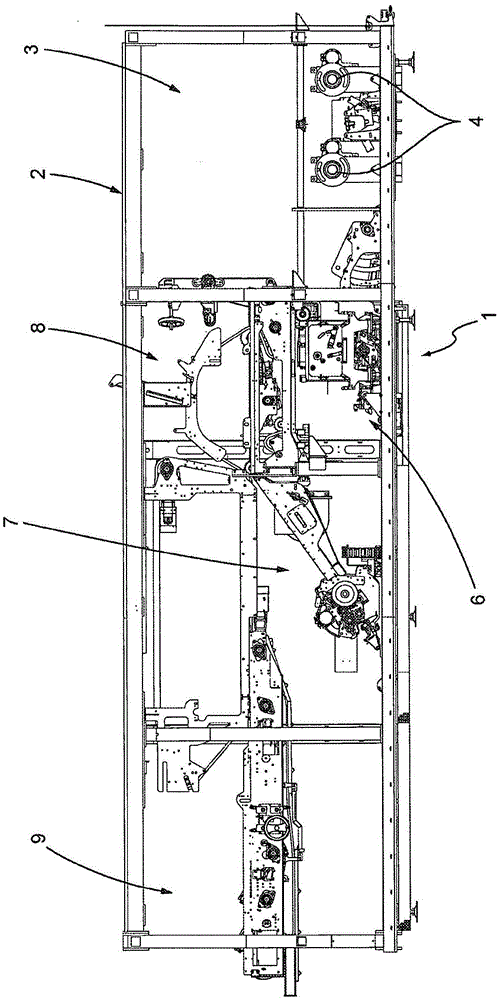

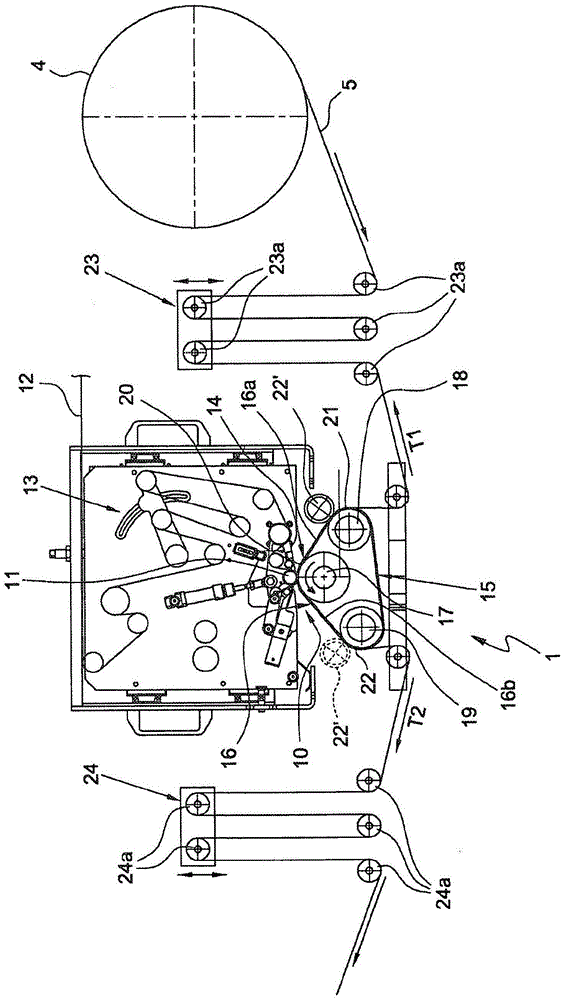

Device and process for applying gripping handles on packaging films and shrinkwrap packer provided with such a device

The present invention concerns a device (1) for applying gripping handles (M) on films (P), being supplied on shrinkwrap packers (2) for making bundles di bottles (B), cans and / or similar containers (B). The device (1) comprises: an applying head (10) provided with a roller (11) for applying gripping handles (M); an abutment mechanism (14) for operatively supporting a series of heat-shrinkable packaging films (P), being supplied on a respective shrinkwrap packer (2). The applying roller (11) and the abutment mechanism (14) are mobile with respect to one another between a non- operating condition, in which they are spaced apart, and an operating condition, in which the applying roller (11) is arranged, at the abutment mechanism (14), against at least one of the films (P) being supplied to apply a respective gripping handle (M) on the latter. The abutment mechanism (14) comprises a supporting tape (15) having an advancement surface (16) for advancing the films (P), which, in the operating condition, provides an abutment for the applying roller (11), which applies each handle (M) on a respective packaging film (P), acting against the advancement surface (16) of the supporting tape (15).

Owner:OCME OFFICINA COSTR MECEGNICHE EMILIANA

A method for fractionally extracting nutrients from spirulina

ActiveCN104086649BGuaranteed not to be brokenHigh energy consumptionDepsipeptidesHigh concentrationPhosphate

The invention provides a method for extracting nutrients from spirulina in a grading manner. Mashed fresh spirulina is used as raw material and dehydrated by using high-concentration ethanol, chlorophyll and carotenoid are simultaneously extracted from the mashed spirulina, and phycobiliprotein and water-soluble polysaccharide are extracted from the spirulina residue (which is subjected to ethanol extraction) by using a phosphate buffer solution. The method has the characteristics of low energy consumption and low cost, multiple nutrients in the spirulina can be obtained by grading extraction, the extraction condition is mild, and the extracted nutrients are unlikely to be destroyed.

Owner:藻能珍稀生物科技研发(广州)有限公司

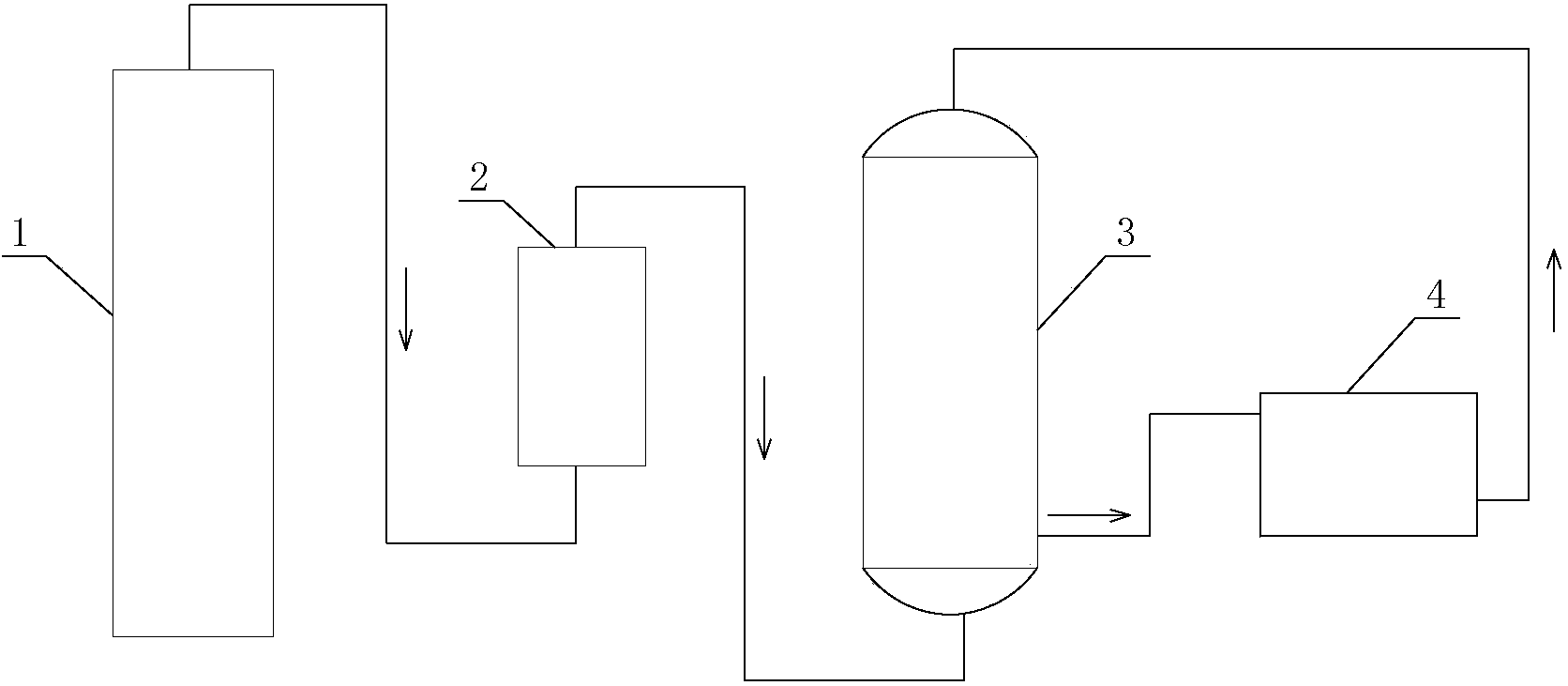

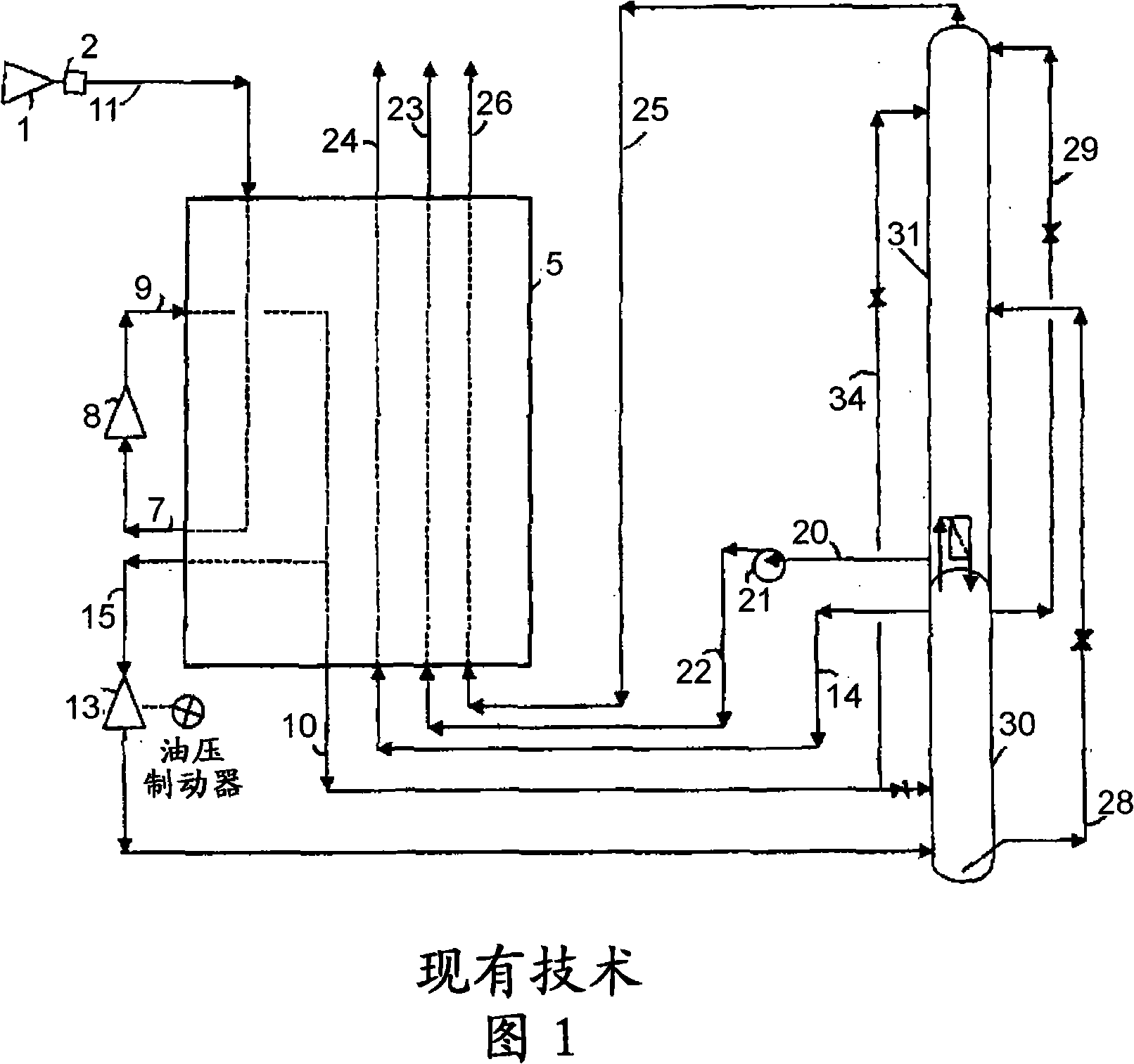

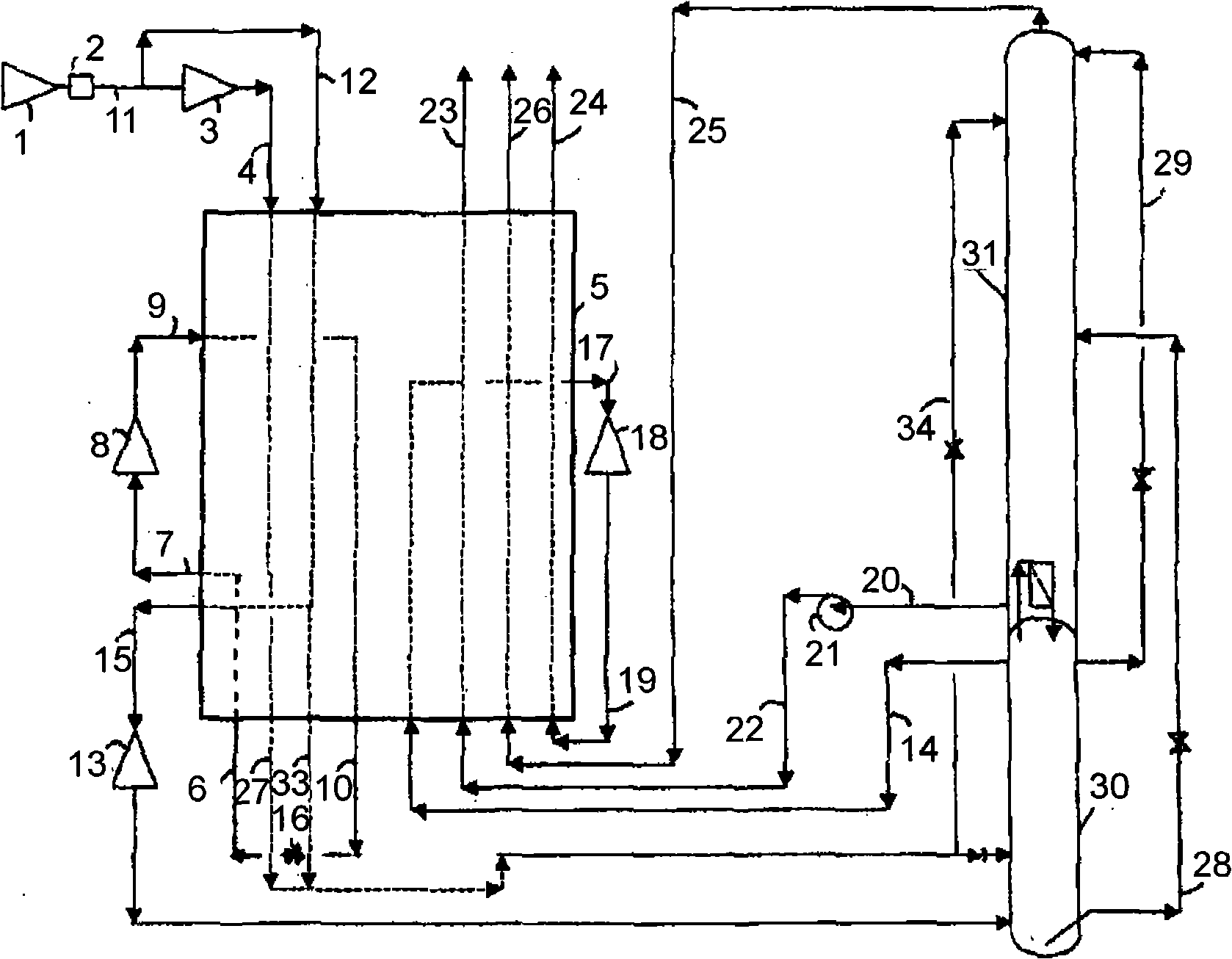

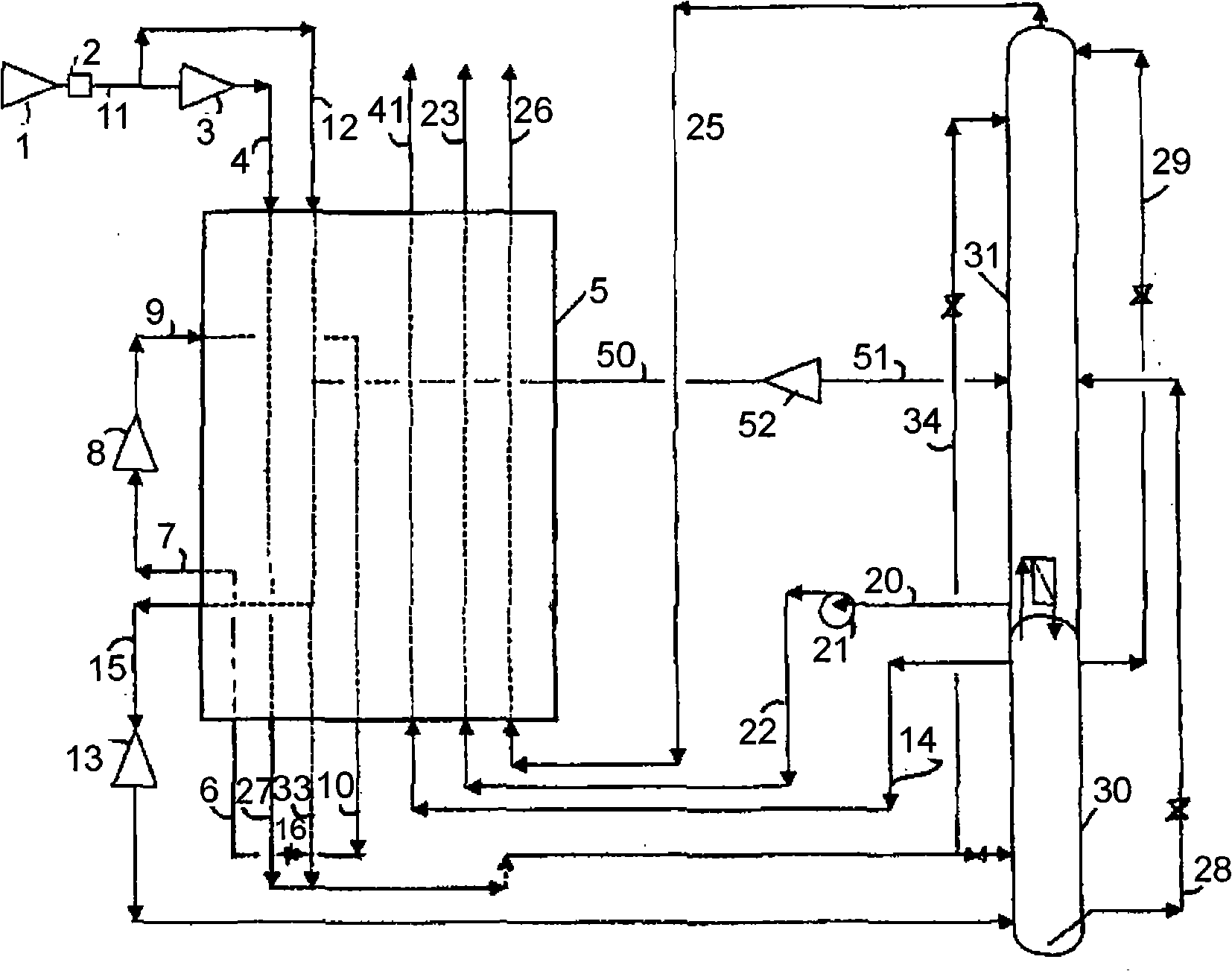

Process and apparatus for the separation of air by cryogenic distillation

InactiveCN101268326ASmall sizeLower total production costSolidificationLiquefactionAir compressionDistillation

A process for separating air by cryogenic distillation in a column system comprising a high pressure column and a low pressure column comprises compressing all the feed air in a first compressor (1) to a first outlet pressure, sending a first part of the air at the first outlet pressure to a second compressor (3) and compressing the air to a second outlet pressure, cooling at least part of the air at the second outlet pressure in a heat exchanger (5) liquefying at least part of the air at the second outlet pressure and sending the liquefied air to at least one column of the column system wherein at least 50% of the liquefied air sent to the column system has been compressed in the second compressor, cooling a second part of the air (12) at the first outlet pressure in the heat exchanger and expanding at least part of the second part of the air in an expander (13) from the first outlet pressure to the pressure of a column (30, 31) of column system and sending the expanded air to that column, at least partially vaporizing an auxiliary fluid (6) , eventually further warming said auxiliary fluid in the heat exchanger, sending at least part of this auxiliary fluid to a third compressor (8) to a third outlet pressure, introducing at least part (9) of said auxiliary fluid at said third outlet pressure in the heat exchanger, cooling said auxiliary fluid and at least partially liquefying said auxiliary fluid, removing said auxiliary stream (10) from the heat exchanger and expanding (16) it to a fourth pressure level before reintroducing it in the heat exchanger where it will be partially vaporized as above- mentioned, removing liquid (20) from a column (31) of the column system and vaporizing the liquid by heat exchange in the heat exchanger.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

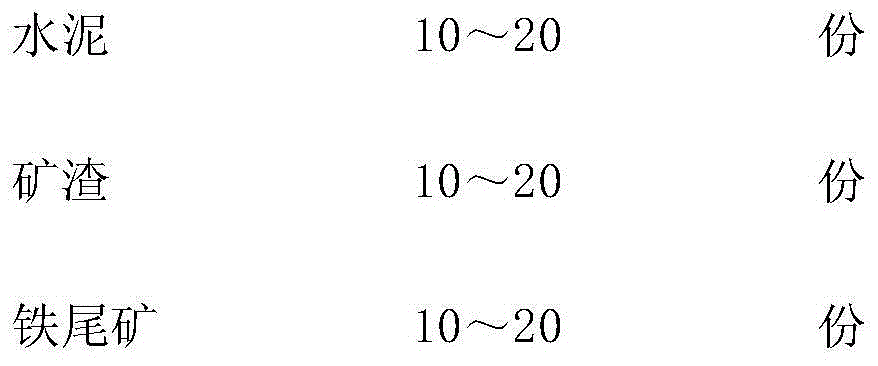

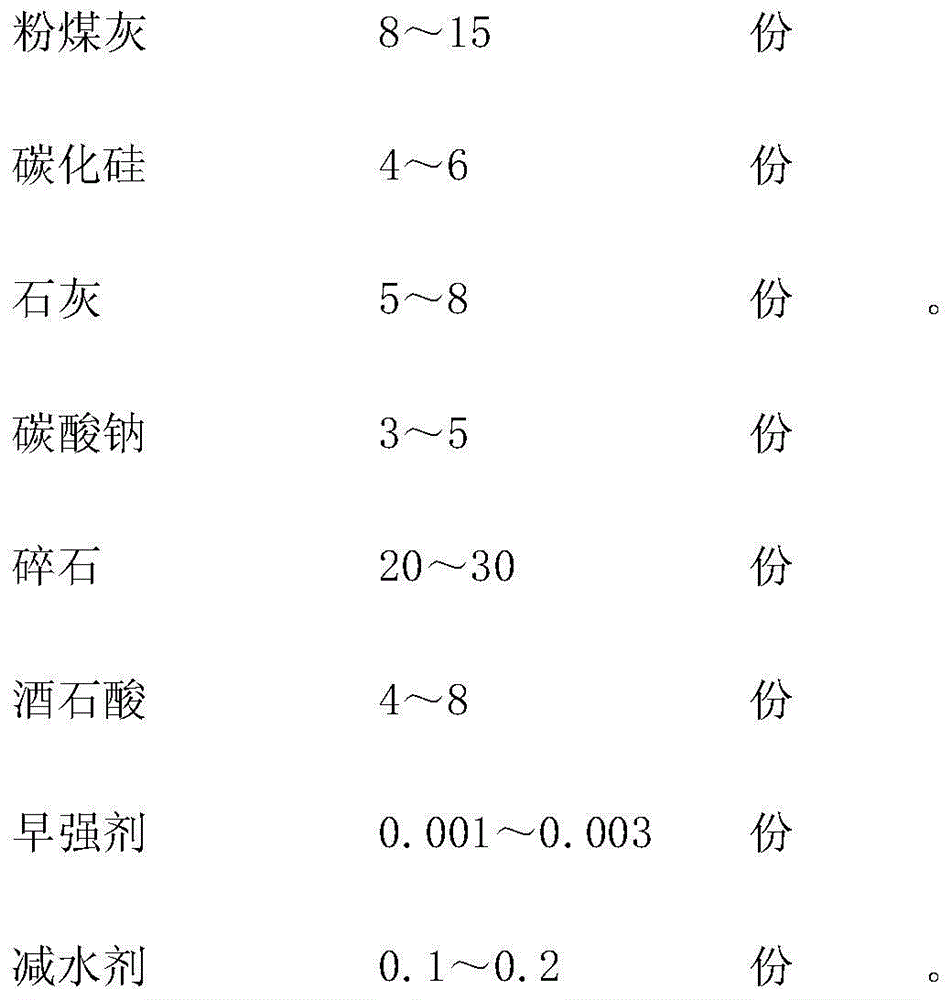

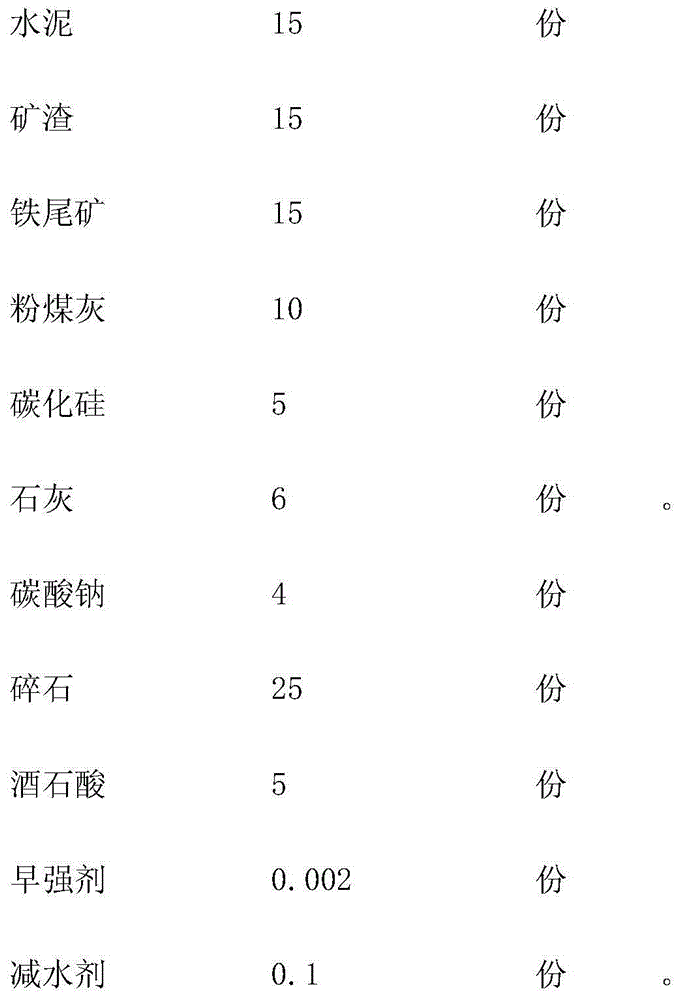

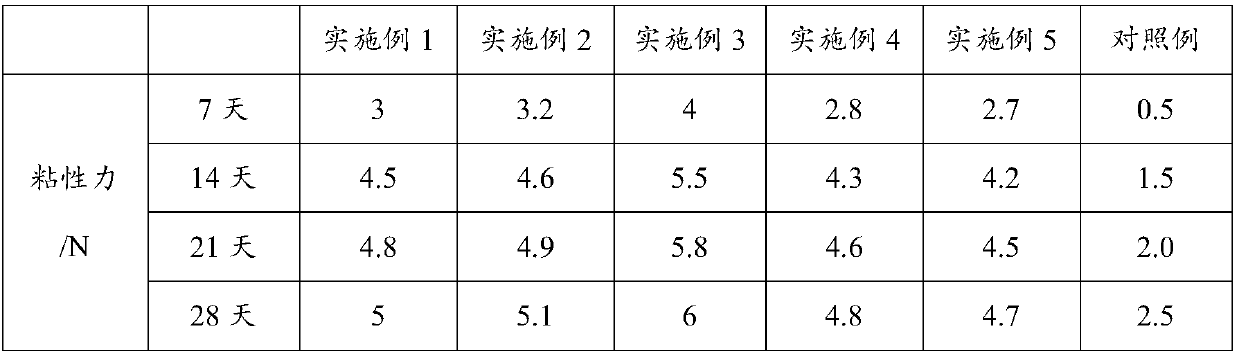

High strength pre-stressed concrete pipe pile and preparation method thereof

The invention relates to a high strength pre-stressed concrete pipe pile, which comprises cement, mineral slag, iron tailing, fly ash, silicon carbide, lime, sodium carbonate, broken stone, tartaric acid, early strong agent, and water reducer. The pipe pile is prepared by the following steps: weighing the components mentioned above, adding water, evenly stirring, casting the mixture into a mould, carrying out centrifugal moulding, and finally performing steam curing under a normal pressure to obtain the finished product. The components cooperate with each other to generate a synergetic effect, the strength of finished product is larger than 100 Mpa, moreover, the cost is proper, the production technology is simple and convenient, the curing is carried out without high pressure, the energy is saved, and the total production cost is reduced.

Owner:TIANJIN SOLID ANTI CEMENT COMPONENT CO LTD

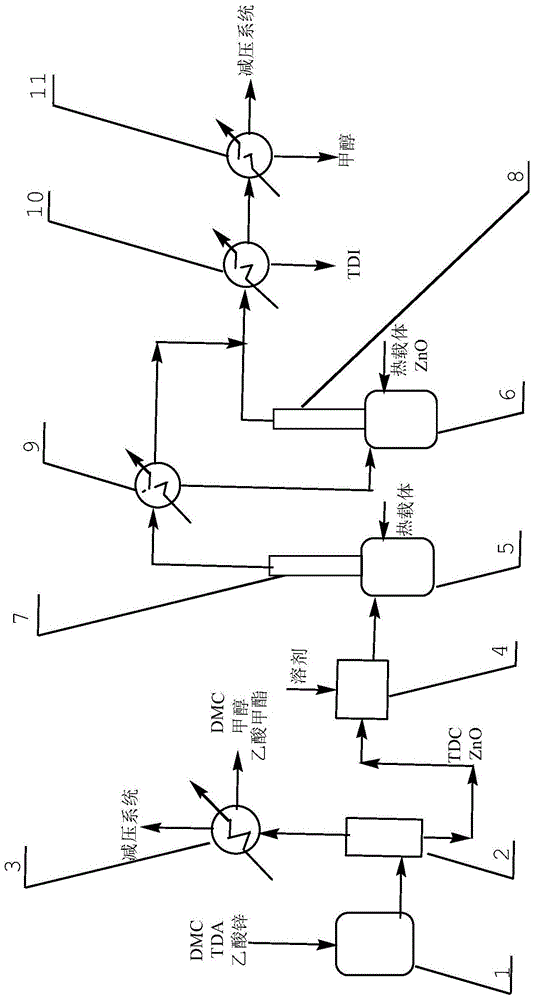

Process for preparing toluene diisocyanate (TDI) by using toluenediamine and dimethyl carbonate

ActiveCN103936623BSimple processHigh yieldPreparation from carbamatesToluene diisocyanateMethyl carbonate

The invention relates to a process for preparing toluene diisocyanate (TDI) by using toluenediamine and dimethyl carbonate. According to the process, a deactivation catalyst, namely zinc oxide (ZnO), of a reaction, which is used for synthesizing toluene dicarbamate (TDC) through catalyzing toluenediamine and dimethyl carbonate by zinc acetate, is used as a catalyst of a reaction for TDC decomposed TDI preparation, the deactivation catalyst, namely ZnO, of the reaction is not required to be separated from the product TDC and is directly applied to the reaction for TDC decomposition catalyzed TDI preparation, and a TDC decomposed TDI preparation process adopts that decomposition reactors of two stages are in series connection and a fractional condenser is arranged between the decomposition reactors of two stages. According to the process, TDC is synthesized through catalyzing toluenediamine and dimethyl carbonate by zinc acetate, and the deactivation catalyst, namely ZnO, of TDC synthesis is selected as an efficient catalyst for TDC decomposition reaction, so that the catalysis effect is good, and the yield of TDI is high; and the temperature of the TDC decomposition reaction is low, so that the total production cost can be greatly reduced.

Owner:HEBEI UNIV OF TECH

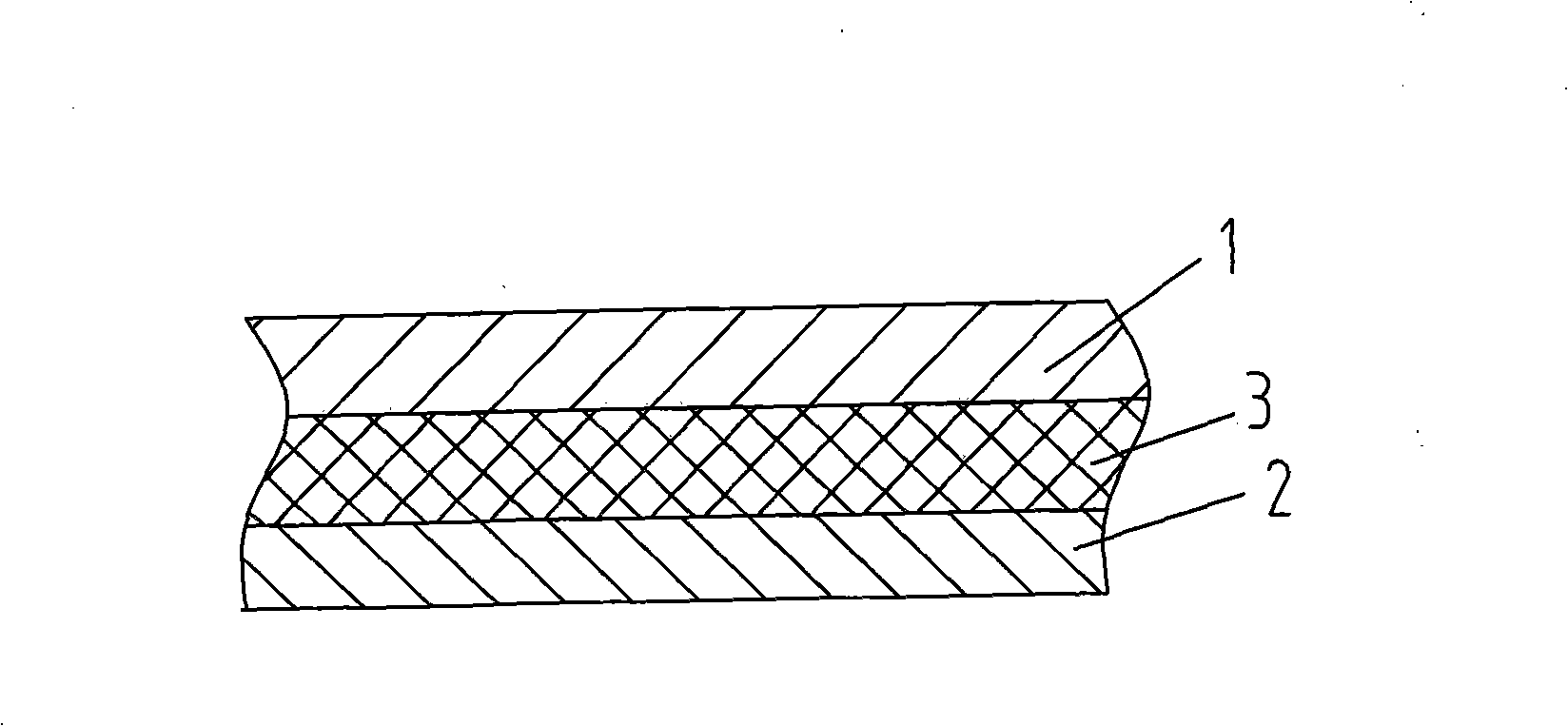

Woven block-blanket and preparation technique

InactiveCN101342046AReduce dosageLower total production costFibre treatmentFloor carpetsPolymer adhesiveChemistry

The invention discloses a woven carpet piece, which comprises a tufted layer and a substrate layer; the tufted layer is bonded with the substrate layer via adhesive to form the tufted layer, the adhesive layer and the substrate layer. The invention solves the deficiencies of the prior art, and bonds the tufted layer with the substrate layer via a polymer adhesive layer, and the two layers only need one set of device and one process to directly produce finished products unlike the prior production devices, thereby the production method greatly simplifies the production process, saves the amount of adhesive, decreases two-sided coating layer, thus greatly reducing the total production cost of the carpet.

Owner:CHANGZHOU AROUND GLOBE CARPET MFG

Black wrapping film and preparation method thereof

InactiveCN107915891ADoes not affect stickinessDoes not affect release rateLow-density polyethyleneMasterbatch

The invention discloses a black wrapping film and a preparation method thereof. The black wrapping film is prepared from the following raw materials: 37 to 99.6 parts of linear low density polyethylene, 0 to 50 parts of metallocene linear low density polyethylene, 0.2 to 10 parts of black masterbatch, 0.2 to 10 parts of viscosity-increasing masterbatch, 0 to 30 parts of reclaimed material; whereinthe black masterbatch is prepared from 40 to 70 parts of polyethylene, 20 to 55 parts of carbon black, 5 to 30 parts of polyethylene wax with number average relative molecular mass of 1000 to 4000; the viscosity-increasing masterbatch is prepared from 40 to 70 parts of polyethylene and 30 to 60 parts of polyisobutene in parts by mass. The raw materials are uniformly mixed to prepare the wrappingfilm by adopting a film casting method, wherein the temperature of film forming is 170 to 290 DEG C, the temperature of a cooling roller is 15 to 35 DEG C and the speed ratio is 1.01 to 1.2. Accordingto the invention, relatively less viscosity-increasing masterbatch is used, the better viscidity is obtained, the release of the viscidity is quick, the delivery cycle is greatly shortened; meanwhile, the reclaimed material is adopted, the cost is lower, the environment influence is less, the preparation method is simple and convenient, the requirement on production equipment is low and easy to control, and the preparation method is suitable for continuous production.

Owner:XIAMEN JUFU PLASTIC PRODS

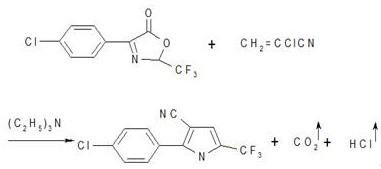

Method for producing chlorfenapyr intermediate pyrrole by replacing acetonitrile with solvent DMF

PendingCN112608268ASolve technical problemsImprove production efficiencyOrganic chemistryPyrroleEnvironmental chemistry

The invention provides a method for producing chlorfenapyr intermediate pyrrole by replacing acetonitrile with a solvent DMF. The solvent DMF is used for replacing acetonitrile. The method for producing the chlorfenapyr intermediate pyrrole by replacing acetonitrile with the solvent DMF comprises the following steps: extraction replacement, heat preservation reaction and condensation desolvation. The method has the beneficial effects that the reaction temperature of the pyrrolation cyclization reaction for preparing the intermediate is increased to 80 DEG C, the yield is increased to 90% or above in a breakthrough manner, the consumed solvent amount is reduced by more than 30%, the production cost is reduced by about 86%, the production cost is greatly reduced, and the production burden of enterprises is reduced.

Owner:李通

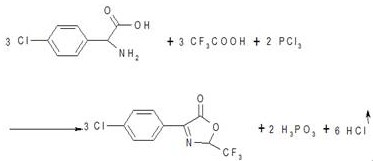

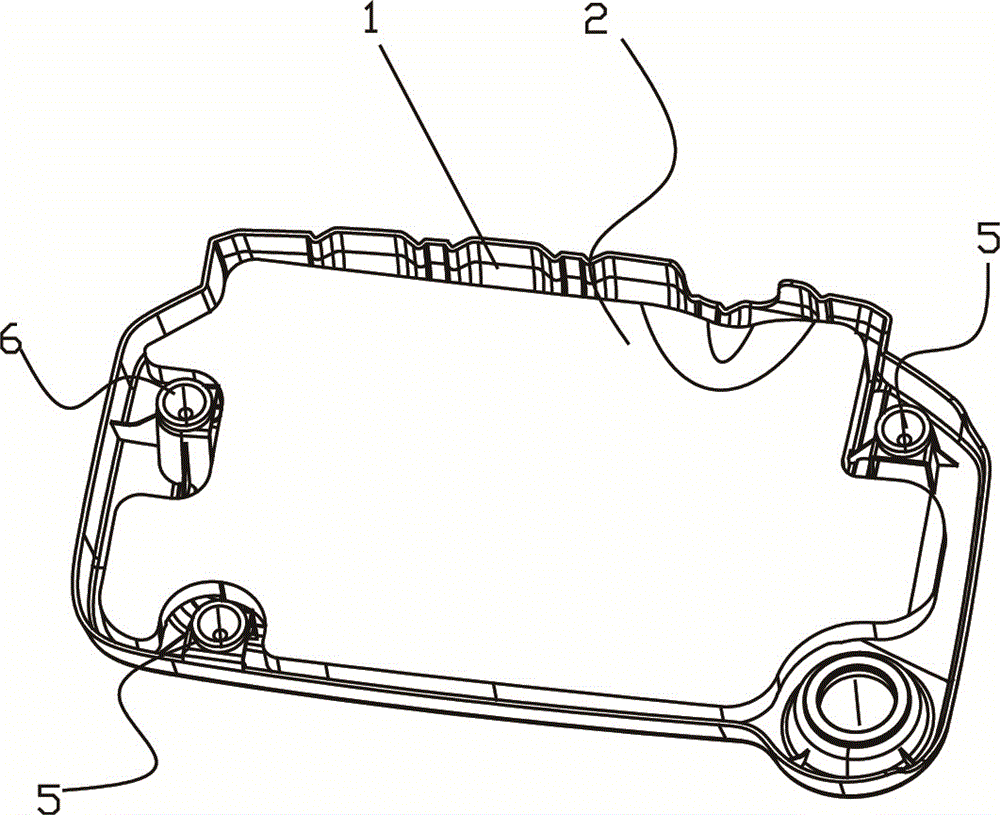

Vehicle engine cover adopting foam molding process

InactiveCN105422312ALow costLower total production costCasingsMachines/enginesThermal insulationNoise reduction

The invention discloses a vehicle engine cover adopting a foam molding process. The vehicle engine cover comprises an engine cover body, and a bushing arranged on the engine cover body; the engine cover body is integrally molded through a PUR all-water foaming self-skinning process; reinforcing ribs are arranged on the back surface of the engine cover body in a criss-cross manner; and support blocks for achieving a support effect are arranged on the side walls of the reinforcing ribs. The engine cover has a decoration effect, and is more excellent in protection function; the thermal insulation, sound absorption and noise reduction indexes and performances are promoted by 30%; the formation parts are reduced from 8 to 3; the assembly production procedure and the field transfer are reduced; and the operators are reduced.

Owner:FUCHENG AUTO PARTS

Method for preparing asparagus rutin

InactiveCN1233651CLower total production costThe extraction process is perfect and feasibleSugar derivativesSugar derivatives preparationAlcoholFiltration

A method for preparing asparagus rutin, which is characterized in that asparagus is first cleaned, dried and crushed, and then extracted with alcohol and water according to the weight-to-volume ratio of asparagus powder to alcohol water of more than 1:10-20, so that the contained asparagus Dissolve the D component as much as possible, and then filter the preliminary extract to remove small molecular impurities and decolorize to obtain the extract to be concentrated, then vacuum concentrate it at about 60°C to recover the ethanol in it, and obtain Concentrate, and deproteinize it by trichloroacetic acid method or improved Sevage method, filter to remove the filter residue to obtain filtrate, further add water to it to evaporate the trichloroacetic acid solvent, filter while it is hot, let the filtrate cool to precipitate rutin . The invention has perfect and feasible process, simple operation, saves labor force, reduces the total production cost of asparagus and rutin, and the extraction rate of asparagus and rutin can reach more than 70%, and the purity can reach more than 90%. The present invention can also extract rutin from discarded asparagus plants.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

A pull method crystal growth furnace with coordinated control of thermal field

ActiveCN104514032BIncrease temperatureShorten the chemical timeBy pulling from meltElectrical resistance and conductanceThermal isolation

Owner:HUAZHONG UNIV OF SCI & TECH

Plug-in grabbing fixture

ActiveCN108857304BReduce the number of replacementsThere are few types of useElectric switchesMetal working apparatusAcute angleMechanical engineering

Owner:GIGA BYTE TECH CO LTD

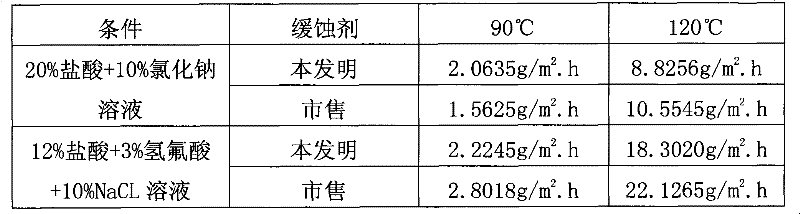

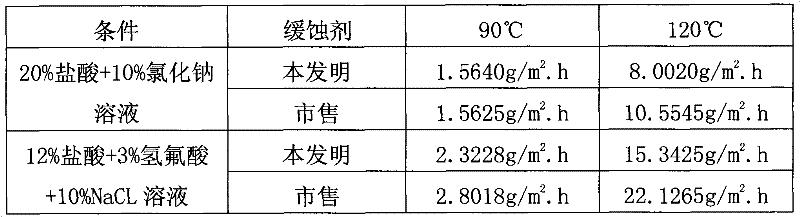

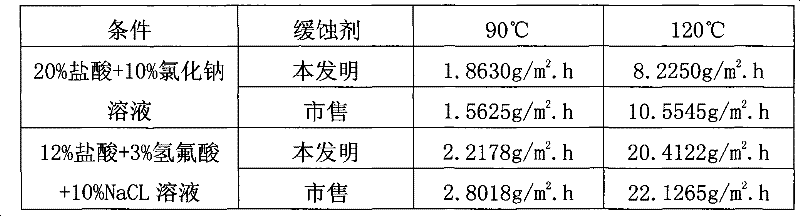

A kind of high temperature acidifying corrosion inhibitor and preparation method thereof

InactiveCN101643642BReduce moisture contentAvoid hydrolysisDrilling compositionBenzyl chlorideAcetophenone

The invention relates to a high-temperature acidification corrosion inhibitor and a preparation method thereof, comprising the following materials: 79.33-87.68 parts of ethanol, 19-21 parts of formic acid, 22.33-24.68 parts of aniline, 31.11-34.39 parts of acetophenone, and 26.13-28.88 parts of formaldehyde , 31.54-34.86 parts of benzyl chloride and 8.55-9.45 parts of propynyl alcohol, place ethanol, formic acid and aniline in the reaction kettle and stir, then add acetophenone into the reaction kettle, and then drop formaldehyde solution into the reaction kettle After adding the formaldehyde solution dropwise, add benzyl chloride into the reactor, lower the temperature of the reactor to room temperature, then add propynyl alcohol and stir. No need to add hydrochloric acid aqueous solution, the water content in the reactor is low, avoiding the hydrolysis of benzyl chloride, which is beneficial to reduce the unit consumption of benzyl chloride in the process of quaternization reaction, before adding formaldehyde dropwise, drop into the reactor The amount of formaldehyde is lower than the reaction molar ratio of synthetic Mannich base, and the formaldehyde is in a state of insufficient amount, which reduces the volatilization of formaldehyde, ensures the health of operators, and is safer.

Owner:SHOUGUANG YUXIN CHEM IND

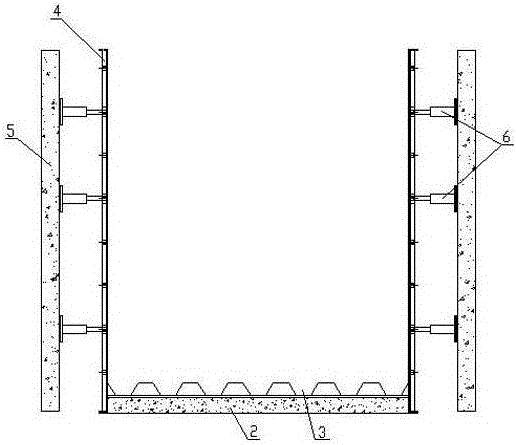

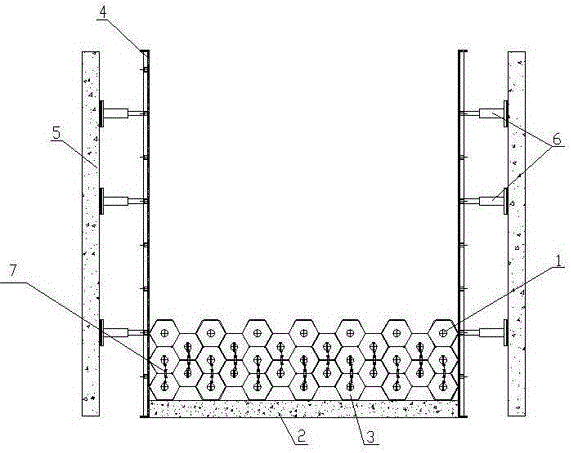

Mold stacking method of high-precision integral anode chamber for conductive FRP electrostatic demister

The invention relates to a mould stacking method of a high precision integral anode chamber for an electro-conductive glass steel electrical demister. The method is characterized by comprising the following steps: preparing a mould, preparing a mould stacking platform, pre-manufacturing anode tubes, stacking the moulds, demoulding, trimming, and sealing the opening. The mould stacking platform comprises a horizontally-arranged base plate, and two vertically-arranged side plates are respectively arranged on the two sides of the base plate. A semi-hexagonal groove, which can accommodate a mould, is arranged on the upper surface of the base plate along the horizontal direction. In the anode tube pre-manufacturing step, uncured semi-finished anode tubes are manufactured on moulds, wherein the number of the moulds is more than that of anode tubes that are required for manufacturing an anode chamber. In the mould stacking step, the uncured semi-finished anode tubes and the moulds are transported to the mould stacking platform as a whole and stacked together. The provided integral anode chamber production method has the advantages of high work efficiency and low total production cost, and moreover the produced integral anode chamber has the advantages of small size deviation and high strength.

Owner:韦捷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com