Plug-in grabbing fixture

A fixture and plug-in technology, applied in the field of fixtures, can solve problems such as high fixture cost and low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

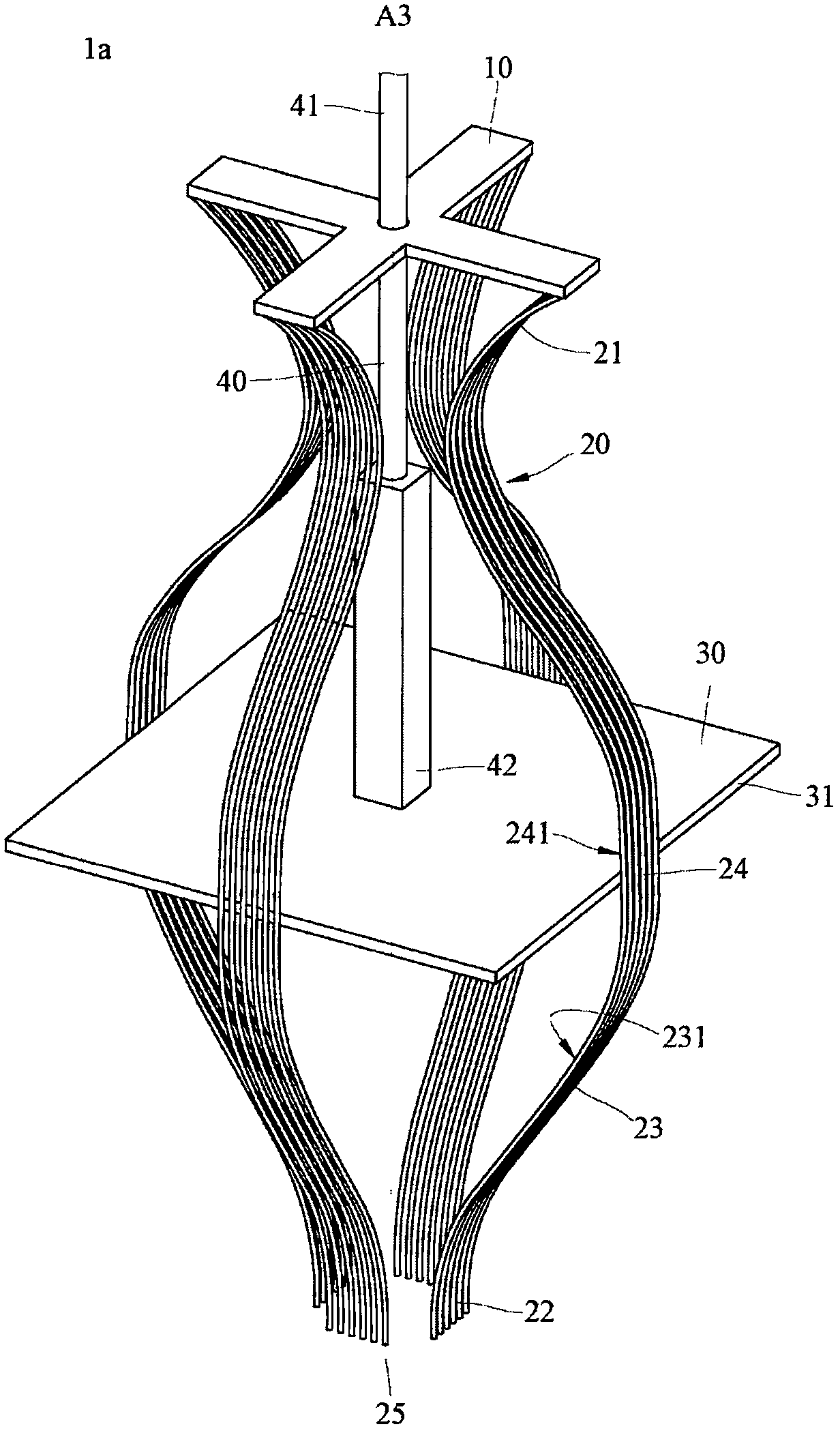

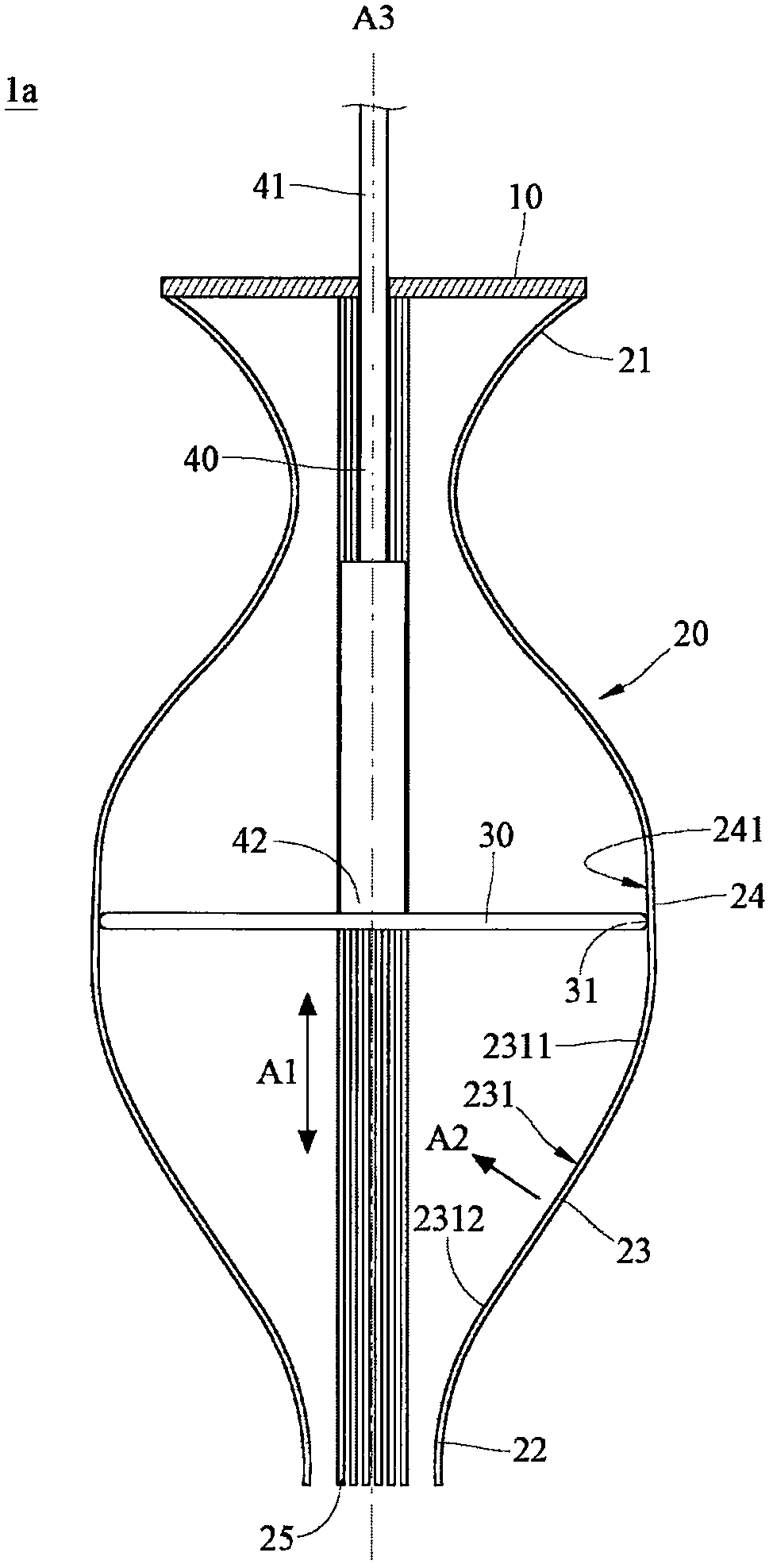

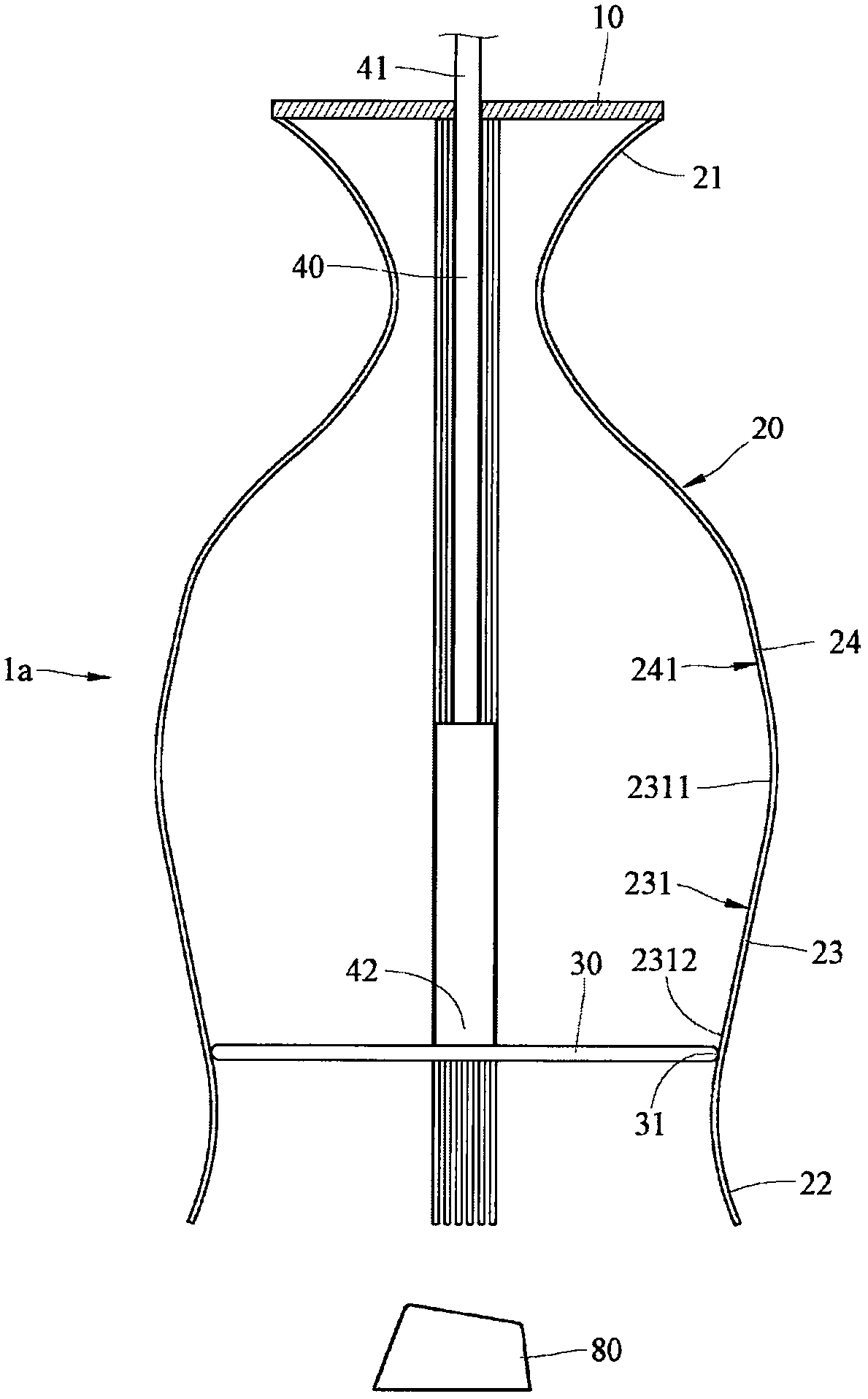

[0045] see Figure 1 to Figure 2 . figure 1 It is a three-dimensional schematic diagram of the plug-in grabbing jig according to the first embodiment of the present invention. figure 2 for figure 1 sectional schematic diagram. In this embodiment, the plug-in grabbing jig 1 a includes a fixing part 10 , a plurality of elastic parts 20 , a pushing part 30 and a connecting part. In this embodiment, the connecting part is a joystick 40 .

[0046] In this embodiment, the fixing member 10 is in the shape of a cross. But this is not taken as an example. In other embodiments, the fixing member 10 may be polygonal or circular.

[0047] Each elastic member 20 includes a connecting section 21 , a grasping section 22 , a first pushed section 23 and a second pushed section 24 . The connecting section 21 of the elastic member 20 is connected to different sides of the fixing member 10 . The gripping section 22 is opposite to the connecting section 21 . The first pushed section 23 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com