Method for producing a hybrid-structure part of a motor vehicle and corresponding hybrid-structure part

A hybrid structure and production method technology, applied to vehicle parts, upper structure, upper structure sub-assembly, etc., can solve the problem that the strength is not enough to withstand impact, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

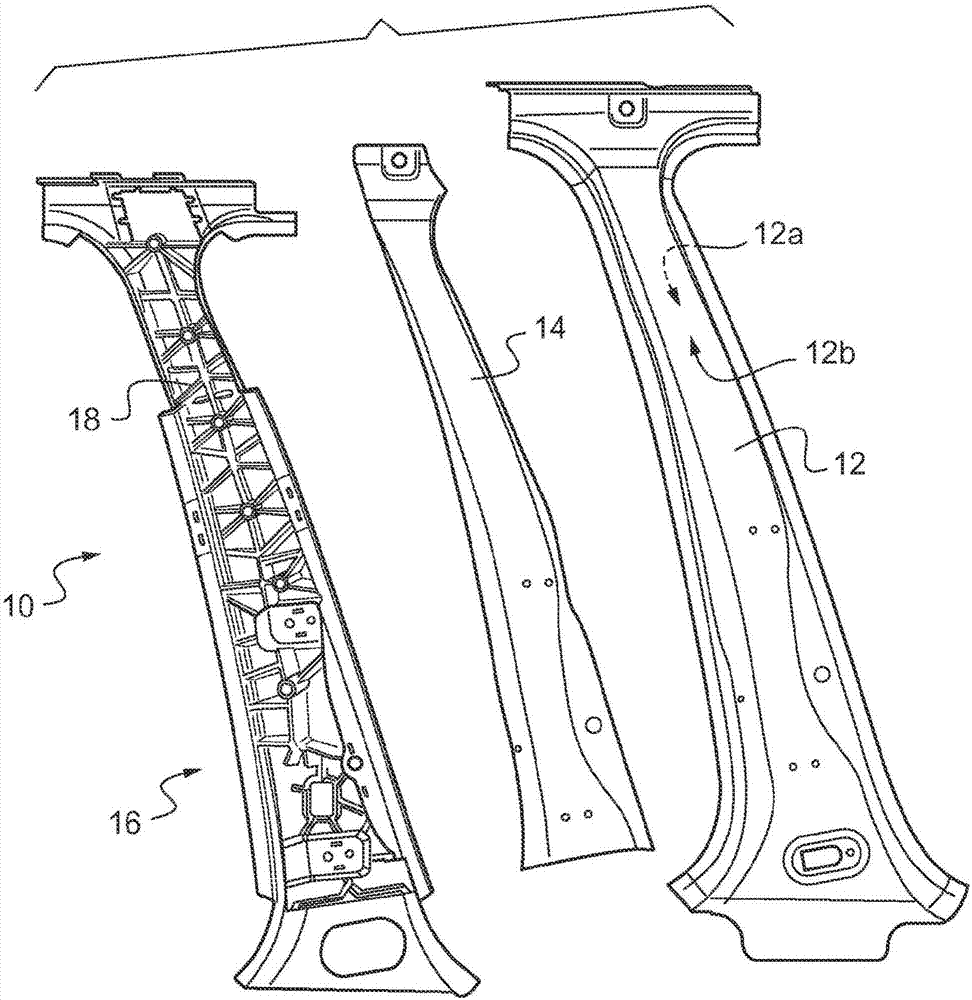

[0095] figure 1 A central structural pillar 10 of a motor vehicle is shown, comprising:

[0096] - shaped metal material sheet 12,

[0097] - shaped composite material panels 14,

[0098] - A molded polymer material 16 which at least partially covers the cladding metal material plate 14 covered with the composite material plate 14, the polymer material 16 optionally forming ribs 18.

[0099] The metal material plate 12 is in the form of a hollow part and has a concave inner surface 12a and a convex outer surface 12b.

[0100] The composite material sheet 14 covers the face 12 a of the metal material sheet 12 . The composite sheet 14 contains several layers of fibers impregnated or embedded in a polymer matrix.

[0101] It should be noted that the invention is not limited to a particular shape of the face 12a of the sheet of metal material 12 on which the sheet of composite material 14 is applied, which face 12a may be a convex face or otherwise.

[0102] The polymer mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com