Vehicle engine cover adopting foam molding process

A technology of engine cover and automobile engine, which is applied in the field of automobile parts, can solve the problems of complex parts composition and production process, high investment in injection molding equipment and molds, poor environmental protection of adhesive process, etc., and achieve the performance improvement of sound absorption and noise reduction indicators, Reduce the assembly and production process and achieve the effect of light weight and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

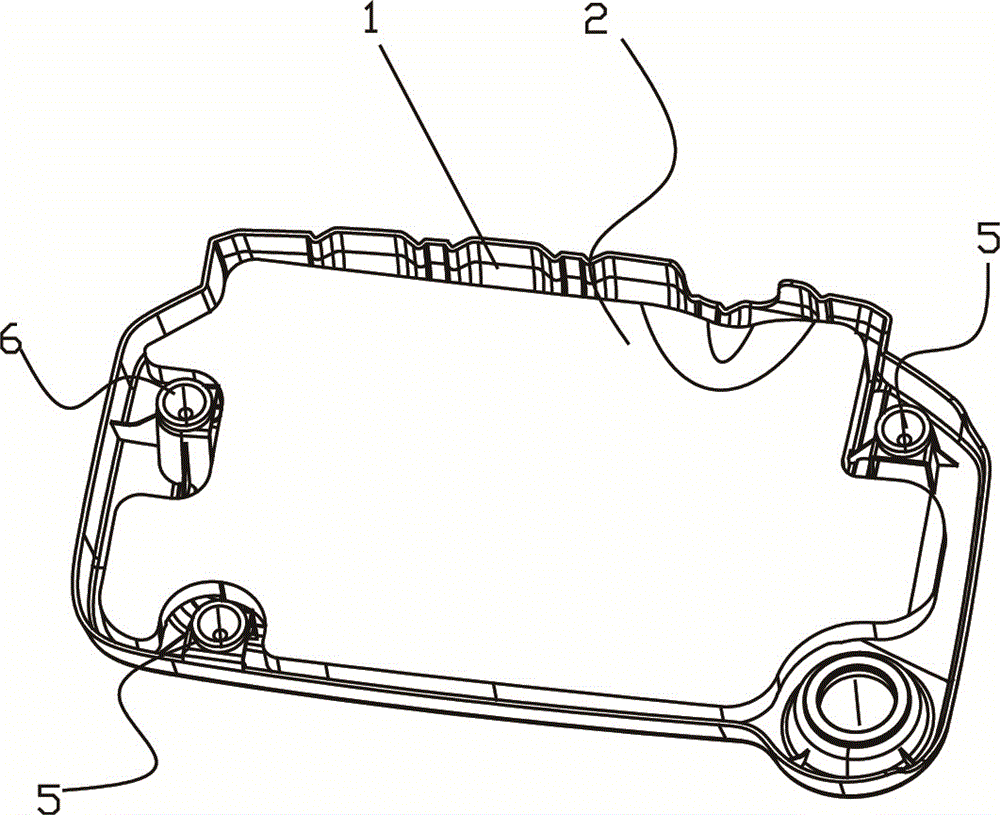

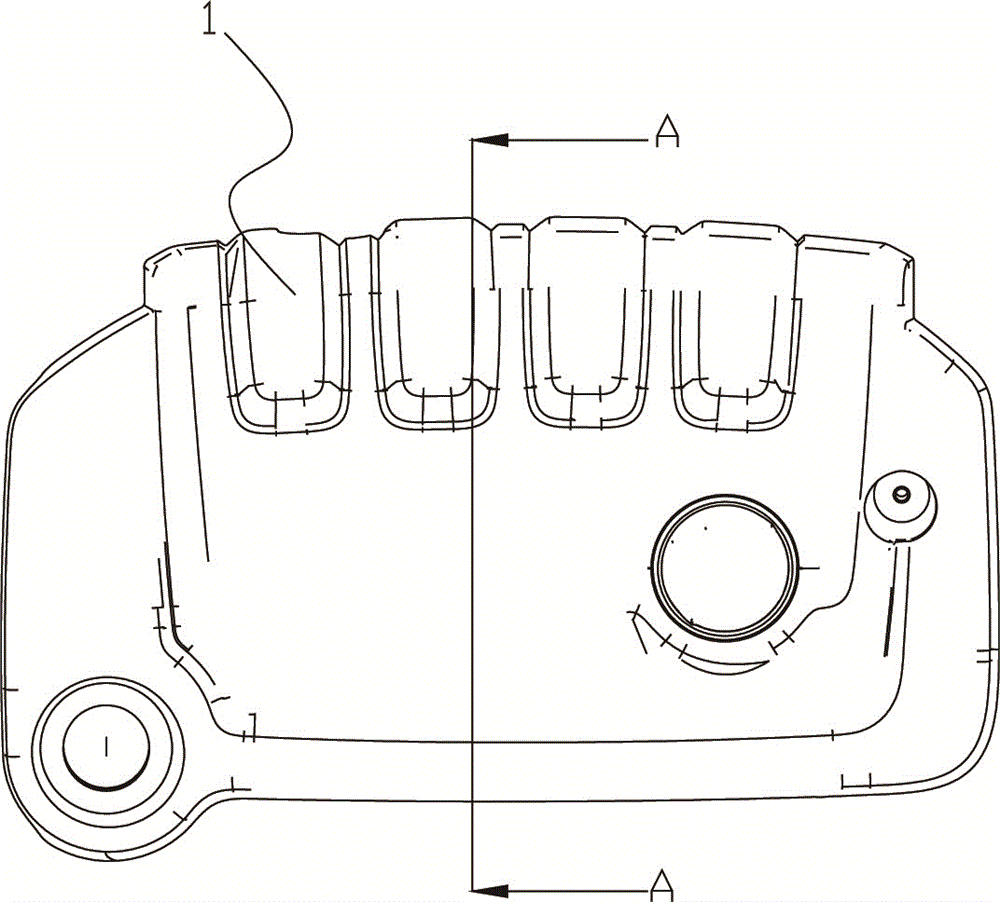

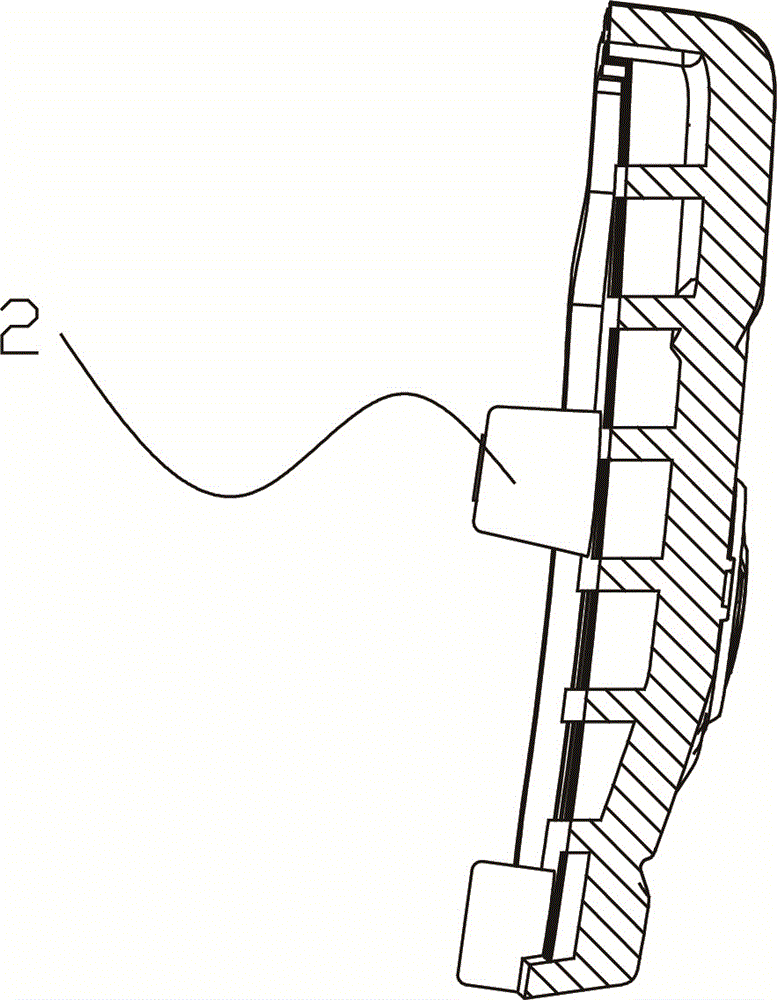

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 2 to Figure 5 , an automobile engine cover adopting a foam molding process, comprising an engine cover body 1 and a bushing 2 arranged on the engine cover body 1, and the engine cover body 1 is self-foamed by PUR full water The skinning process is integrally formed, and the back of the engine cover body 1 is provided with criss-cross reinforcing ribs 3 . The overall strength of the engine cover body is reinforced by the reinforcing ribs 3 . Moreover, the ribs 3 are filled with grooves, which can play a role of sound absorption and noise reduction.

[0013] A supporting block 30 is arranged on the side wall of the reinforcing rib 3, the supporting block 30 is triangular in shape, and the supporting block 30 is used to improve the rigidity of the reinforcing rib 3 to prevent it from being stressed in the lateral direction The prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com