Device and process for applying gripping handles on packaging films and shrinkwrap packer provided with such a device

A technology of packaging film, application device, applied in the direction of packaging paper shrinkage, packaging material feeding device, packaging item type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

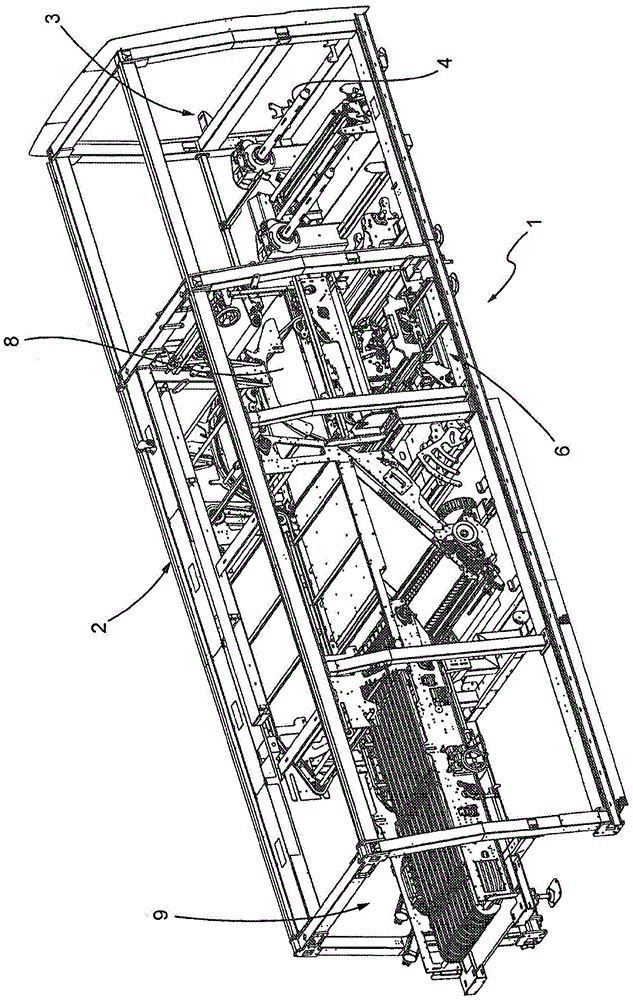

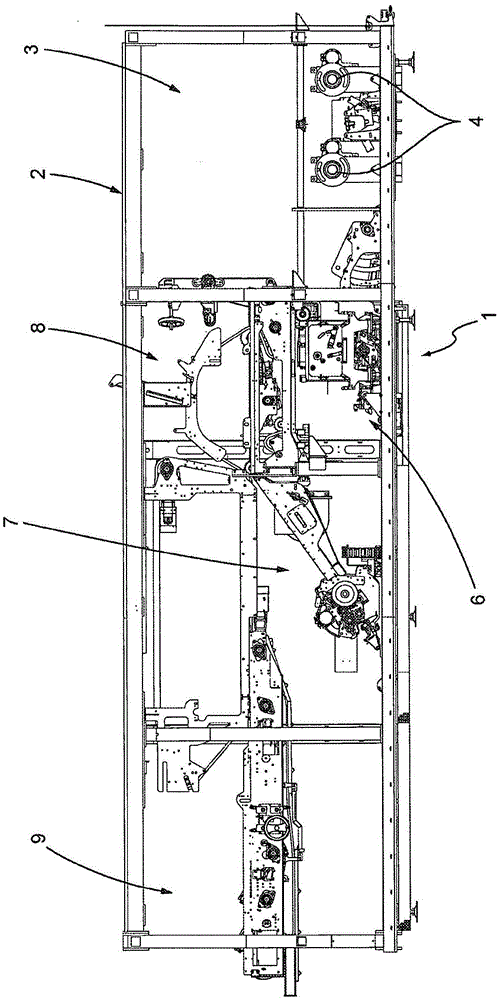

[0041] see Figure 1 to Figure 3 , the reference number 1 indicates in its entirety a device according to the invention for applying a gripping handle to a packaging film supplied on a corresponding shrink-wrapping type baler for forming bottles, cans, and / or bundles of similar containers.

[0042] if available in figure 1 and figure 2 As seen in , the application device 1 is mounted on a bundle F for forming and packaging bottles B, cans and / or similar containers B ( Figure 5c , 5d , 6c and 6d) on shrink-wrapping balers 2.

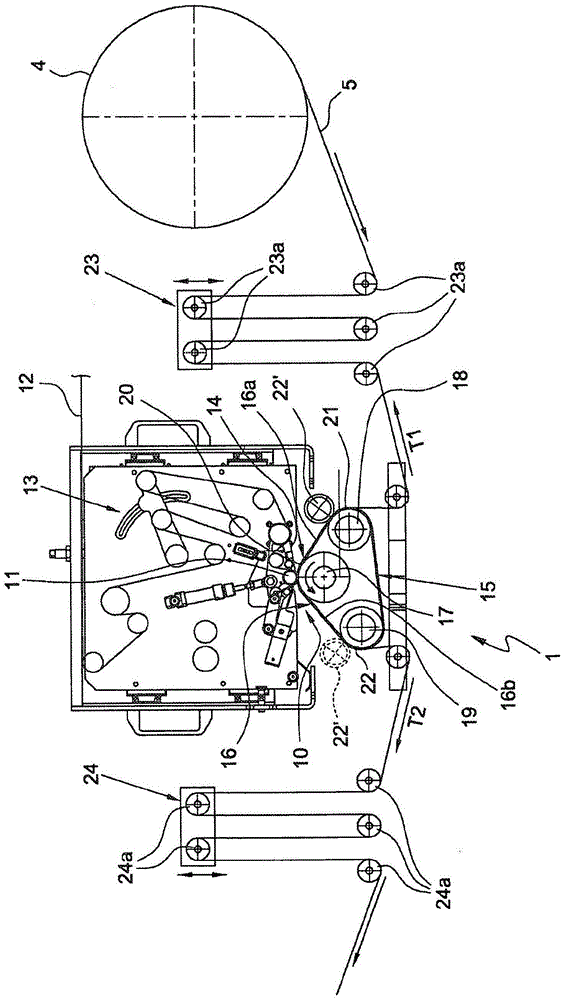

[0043] if available in figure 1 and figure 2 As seen in , the shrink-wrapping baler 2 comprises a tape supply station 3 provided with a continuous belt 5, preferably made of heat-shrinkable plastic material ( image 3 ) of one or more supply reels 4, a series of packaging films P ( Figure 5b and 6b ) are arranged on supply reels, each for forming a corresponding bundle F.

[0044] Adjacent to the supply station 3 and downstream of the supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com