Spin coating device

A spin-coating and coating technology, applied in biochemical cleaning devices, enzymology/microbiology devices, biochemical instruments, etc., can solve the problems of uneven coating, inaccurate test results, low efficiency, etc., and achieve improved uniformity performance, and the effect of improving coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

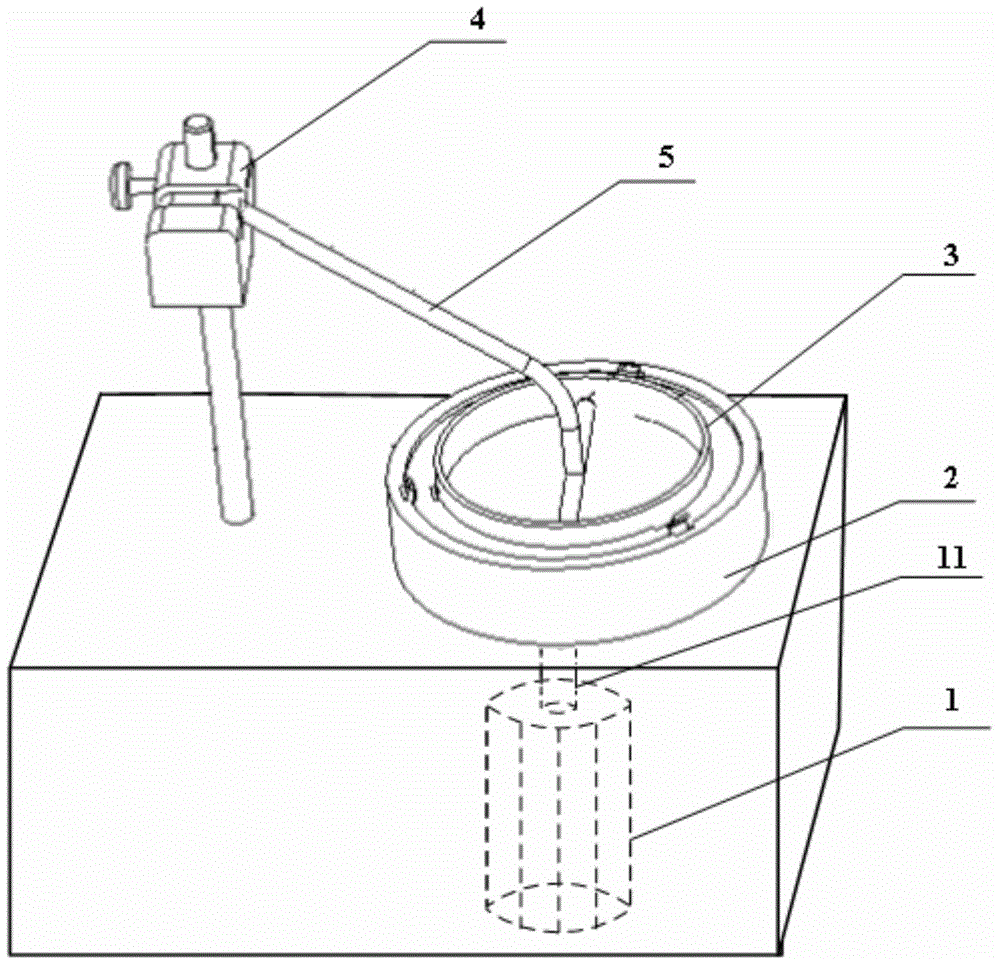

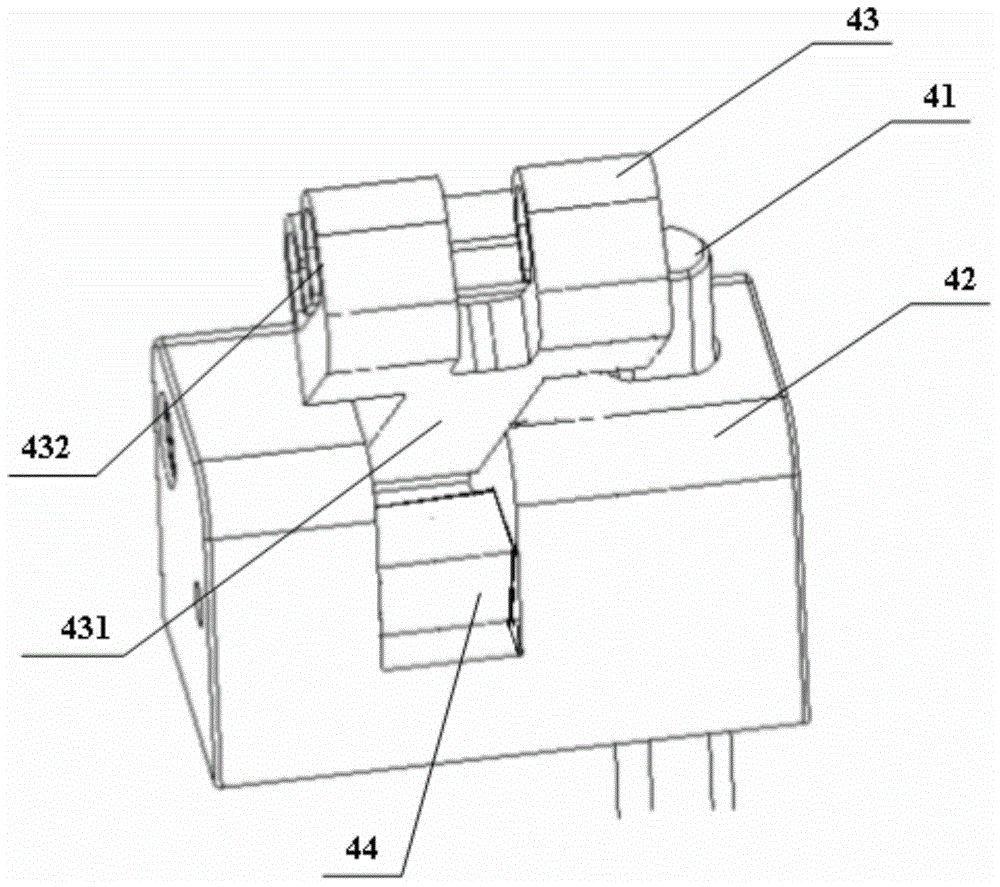

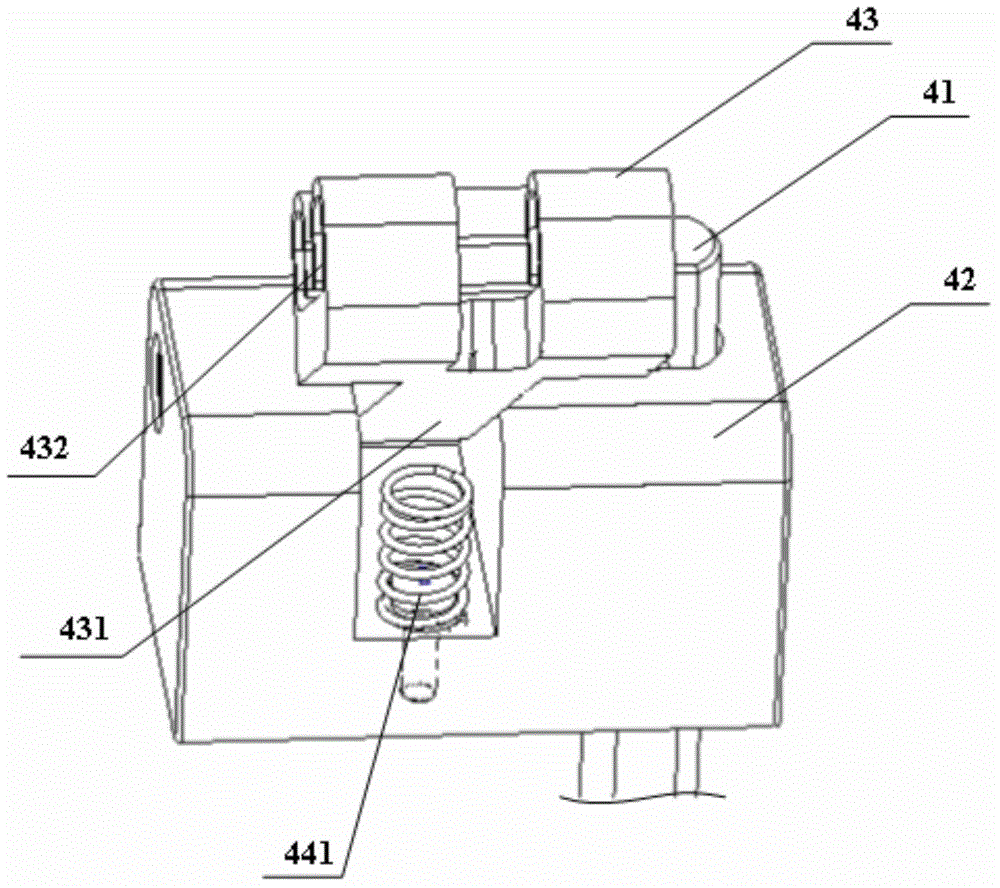

[0038] In order to improve the microorganism coating efficiency, the invention provides a spin coating device. In this technical scheme, the motor can drive the tray to rotate horizontally, and the coating end of the coating rod fixed on the fixed mechanism extends into the petri dish. When microbial coating is required, the experimenter only needs to turn on the motor, and the motor drives The tray rotates, and the coating rod will coat the bacterial solution on the culture medium in the petri dish, which can realize the automatic coating of microorganisms, which greatly improves the coating efficiency. It is necessary to hold the coating rod and apply it back and forth on the medium, so the uniformity of the coating is also improved. In order to make the purpose, technical solution and advantages of the present invention clearer, the following specific examples are given to further describe the present invention in detail.

[0039] Embodiments of the present invention provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com