Pipe fitting automatic electric spark treatment device and method

A processing device and electric spark technology, applied in the direction of coating, metal material coating process, manufacturing tools, etc., can solve the problems of high labor intensity, low efficiency, poor uniformity, etc., and achieve good coating uniformity and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

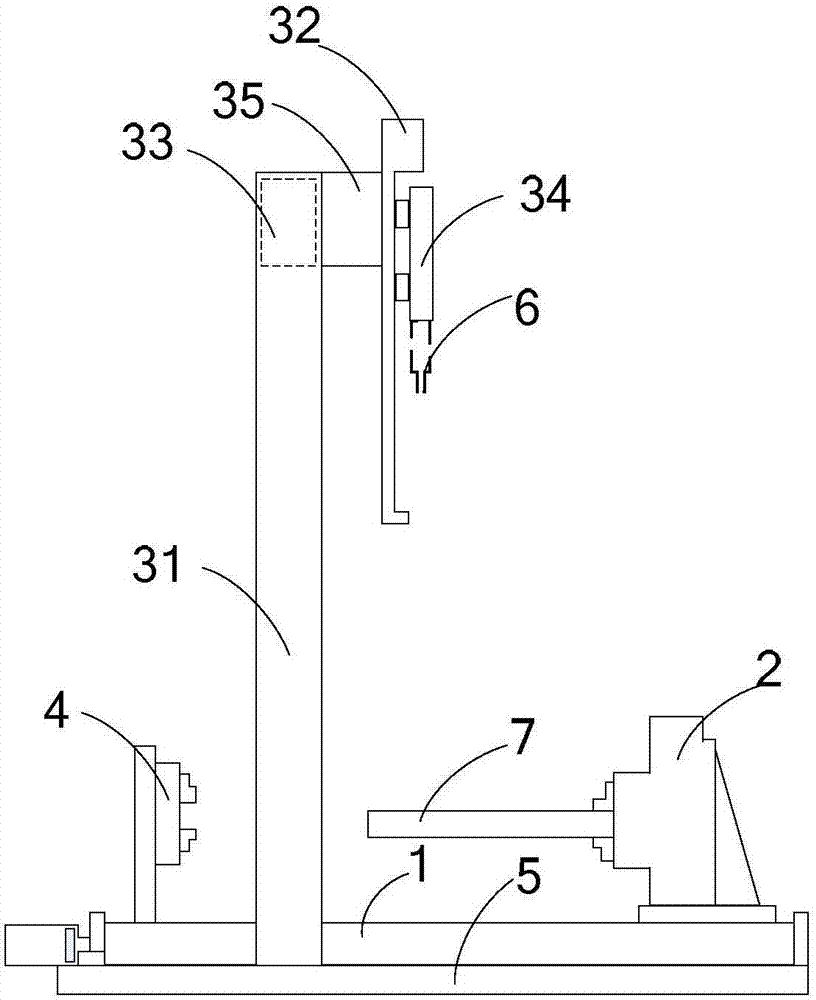

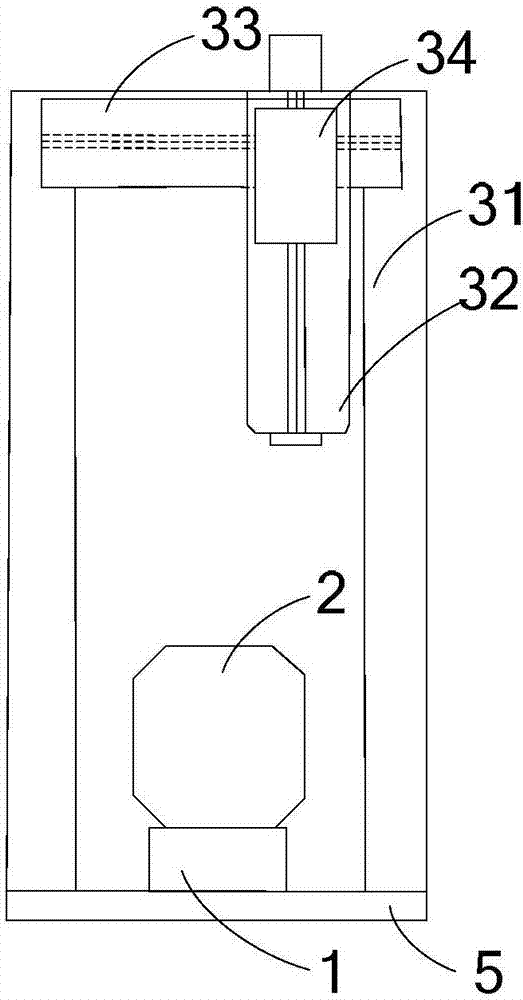

[0062] Embodiment 1: as figure 1 with figure 2 As shown, an automatic electric spark processing device for pipe fittings in this embodiment includes a main mobile platform 1, a rotary chuck 2, a control system, a welding torch mobile platform and a base 5;

[0063] The rotary chuck 2 is used to connect one end of the pipe to be processed 7, the rotary chuck 2 is arranged on the main mobile platform 1, and the control system is used to control the main mobile platform 1 to drive the rotary chuck 2 to move along the axial direction of the pipe to be processed;

[0064] The control system is also used to control the rotary chuck 2 to drive the rotation of the pipe fitting 7 to be processed;

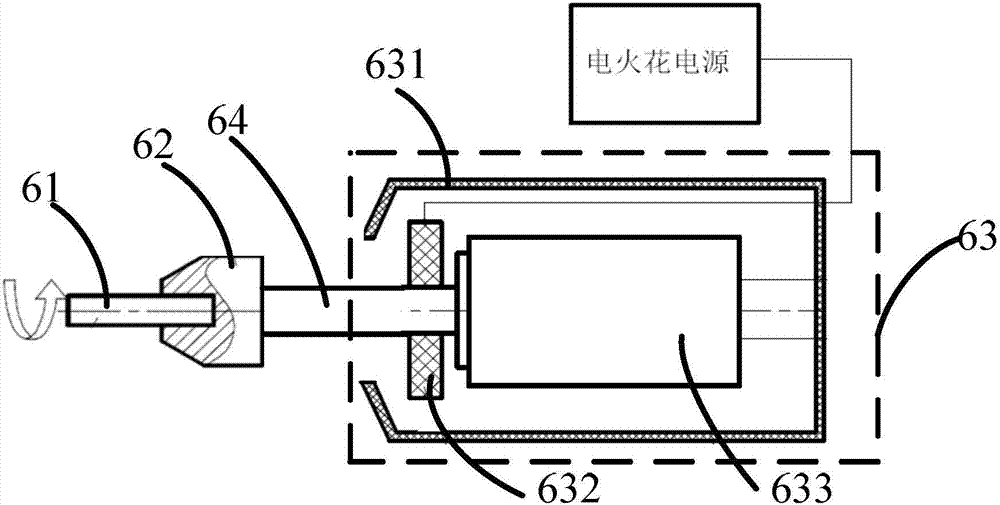

[0065] The electrode of the welding torch 6 is located on the outer or inner surface of the pipe to be processed 7, and the control system is also used to control the work of the welding torch 6;

[0066] The welding torch mobile platform includes a gantry 31, a longitudinal mobile platfo...

Embodiment 2

[0075] Embodiment 2: as figure 1 , figure 2 with Figure 4 As shown, an automatic electric spark processing device for pipe fittings in this embodiment includes a main mobile platform 1, a rotating chuck 2, a control system, a fixed chuck 4 and a welding torch 6;

[0076] The rotary chuck 2 is used to connect one end of the pipe to be processed 7, the rotary chuck 2 is arranged on the main mobile platform 1, and the control system is used to control the main mobile platform 1 to drive the rotary chuck 2 to move along the axial direction of the pipe to be processed;

[0077] The control system is also used to control the rotary chuck 2 to drive the rotation of the pipe fitting 7 to be processed;

[0078] The electrode of the welding torch 6 is located on the outer or inner surface of the pipe to be processed 7, and the control system is also used to control the work of the welding torch 6;

[0079] The fixed chuck 4 is positioned at the other end of the pipe to be processed...

Embodiment 3

[0089] Embodiment 3: Combining Embodiment 1 and Embodiment 2, the inner and outer surfaces are coated simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com