Automatic roll-coating method and automatic roll-coating device of ethanol-permselective composite membrane

A technology that preferentially permeates alcohol and composite membranes. It is used in semi-permeable membrane separation, chemical instruments and methods, and membrane technology. It can solve problems such as unstable performance, low permeation flux, and surface defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

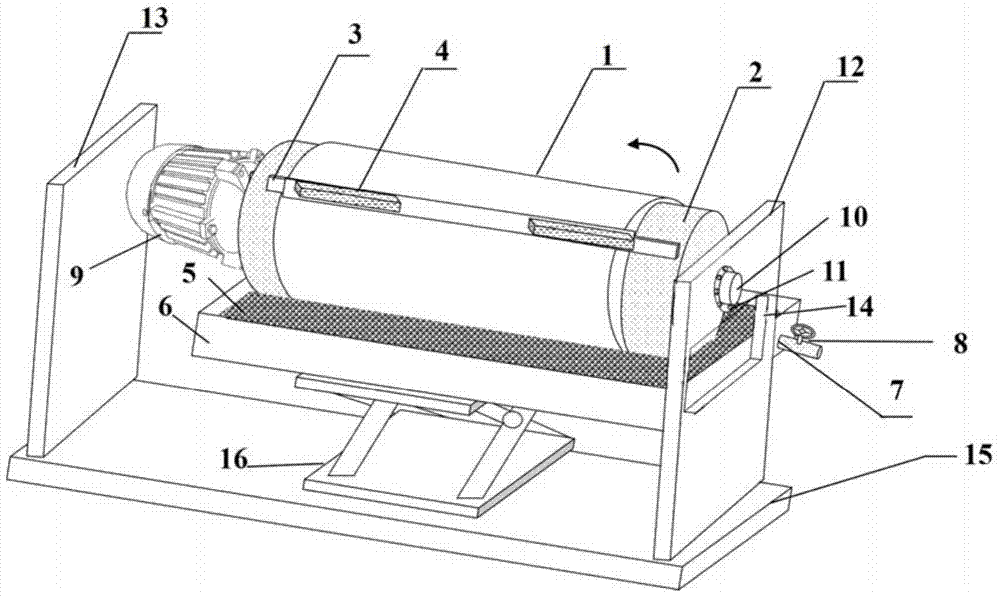

[0034] The base membrane is made of polysulfone (PS) material, a flat ultrafiltration membrane with a molecular weight cut-off of 20,000 and a membrane area of 600cm 2 , the composite material used is polydimethylsiloxane (PDMS, viscosity 2500Pa·S), and the solvent is n-heptane.

[0035] Assembly conditions and methods:

[0036] (1) Polydimethylsiloxane (PDMS) is made into a 10wt% solution with n-heptane, and 1wt% crosslinking agent orthosilicate (TEOS) is added in the solution, and 0.02wt% catalyst dilaurel dibutyltin acid;

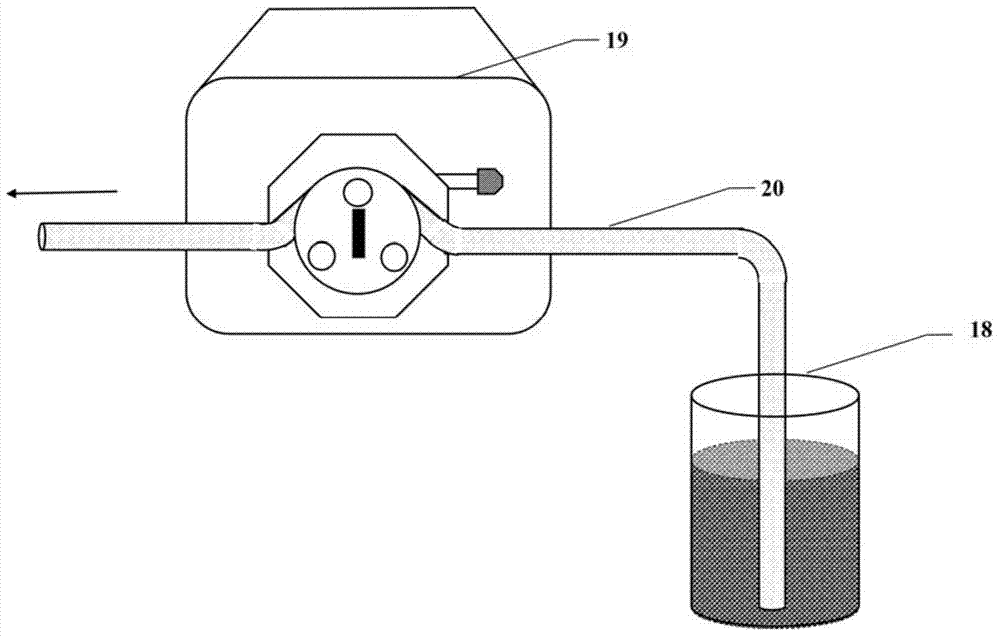

[0037] (2) Pour the above-mentioned feed liquid into the feed storage tank, and transport the feed liquid to the feed liquid tank through the peristaltic pump and hose in the automatic feeding device;

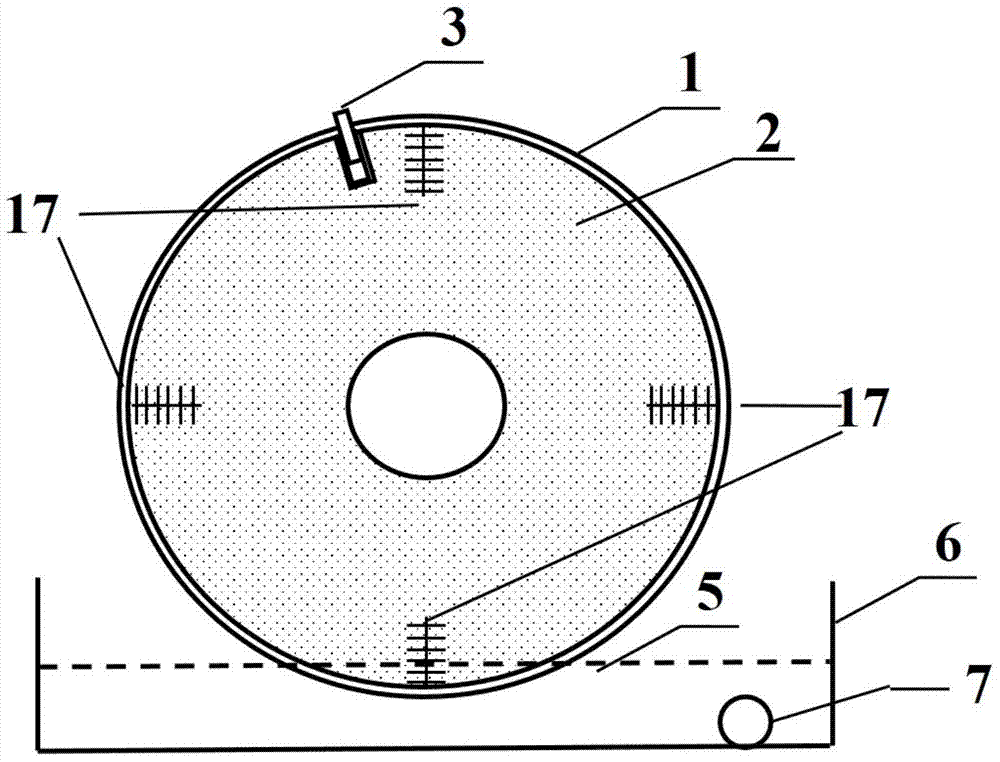

[0038] (3) Fix the two ends of the base film in the groove of the roller of the coating machine with a clamp, adjust the height of the feed liquid tank through the lifting platform and the scale at one end of the roller, so that the lowest outer surfa...

Embodiment 2

[0045] The base membrane is made of polysulfone (PS) material, a flat ultrafiltration membrane with a molecular weight cut-off of 20,000 and a membrane area of 600cm 2 , the composite material used is polydimethylsiloxane (PDMS, viscosity 2500Pa·S), and the solvent is n-heptane.

[0046] Assembly conditions and methods:

[0047](1) Polydimethylsiloxane (PDMS) is made into a 10wt% solution with n-heptane, and 1wt% crosslinking agent orthosilicate (TEOS) is added in the solution, and 0.02wt% catalyst dilaurel dibutyltin acid;

[0048] (2) Pour the above-mentioned feed liquid into the feed storage tank, and transport the feed liquid to the feed liquid tank through the peristaltic pump and hose in the automatic feeding device;

[0049] (3) Fix the two ends of the base film in the groove of the roller of the film coating machine with a clamp, adjust the height of the feed liquid tank through the lifting platform and the scale at one end of the roller, so that the depth of the r...

Embodiment 3

[0056] The base membrane is made of polysulfone (PS) material, a flat ultrafiltration membrane with a molecular weight cut-off of 20,000 and a membrane area of 600cm 2 , the composite material used is polydimethylsiloxane (PDMS, viscosity 2500Pa·S), and the solvent is n-heptane.

[0057] Assembly conditions and methods:

[0058] (1) Polydimethylsiloxane (PDMS) is made into a 10wt% solution with n-heptane, and 1wt% crosslinking agent orthosilicate (TEOS) is added in the solution, and 0.02wt% catalyst dilaurel dibutyltin acid;

[0059] (2) Pour the above-mentioned feed liquid into the feed storage tank, and transport the feed liquid to the feed liquid tank through the peristaltic pump and hose in the automatic feeding device;

[0060] (3) Fix the two ends of the base film in the groove of the roller of the film coating machine with a clamp, adjust the height of the feed liquid tank through the lifting table and the scale at one end of the roller, so that the depth of the rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com