Coating and scraping mechanism and coating device

A coating device and scraping technology, applied in the field of robotics, can solve the problems of poor quality of coating material layers, harm to health and well-being by manual operations, and high labor intensity, so as to reduce labor intensity and cost, simplify construction, and improve The effect of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

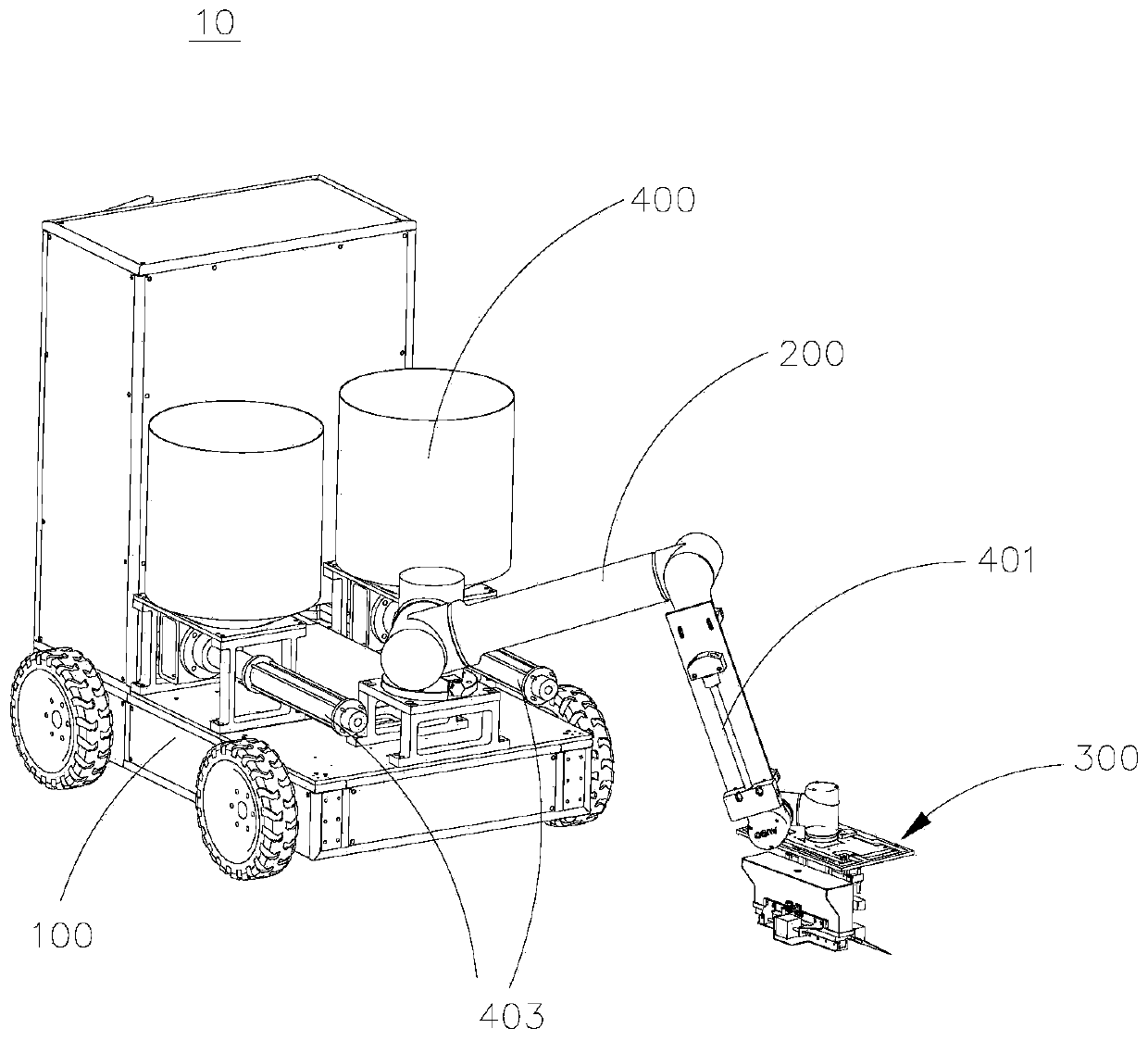

[0053] A coating device 10, which can not only achieve local coating and scraping of materials to be coated, but is also suitable for large-area coating and scraping, especially for coating floor paint. In this embodiment, the application of floor paint is taken as an example The use of the above-mentioned coating device 10 not only realizes the automatic coating of floor paint, but also effectively solves the problems of harm to health, high labor intensity, complicated process and high cost in the existing manual operation in the coating process of floor paint. .

[0054] see figure 1 , the coating device 10 mainly includes: a traveling mechanism, a support 100 , a moving mechanism, a controller (not shown in the figure) and a coating and scraping mechanism 300 .

[0055] Wherein, the traveling mechanism is, for example, a driving wheel, which is arranged on the support 100, and only needs to drive the support to move. In this embodiment, the traveling mechanism and the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com