Device for copper column gate array interconnection device column implanting process

A grid array and device technology, which is applied in the field of copper column grid array interconnection device column planting process devices, and the field of column planting process devices, can solve the problem of increasing production cycle and cost, and difficulty in achieving high-precision centering and positioning and welding of welding columns. Columns are easily scratched, etc., to achieve high interconnection quality and interconnection efficiency, achieve interconnection quality and interconnection efficiency, and ensure the effect of coplanarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

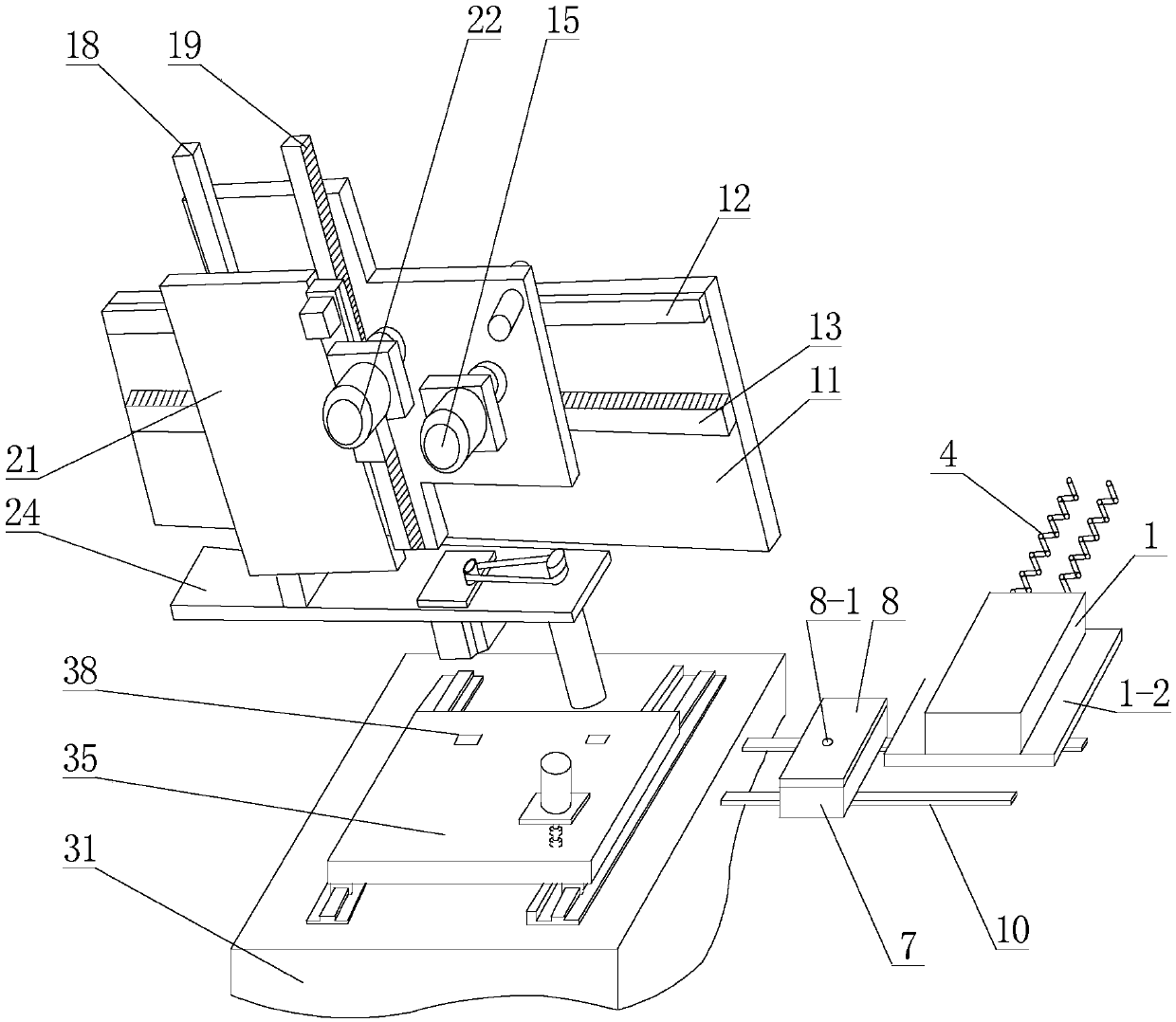

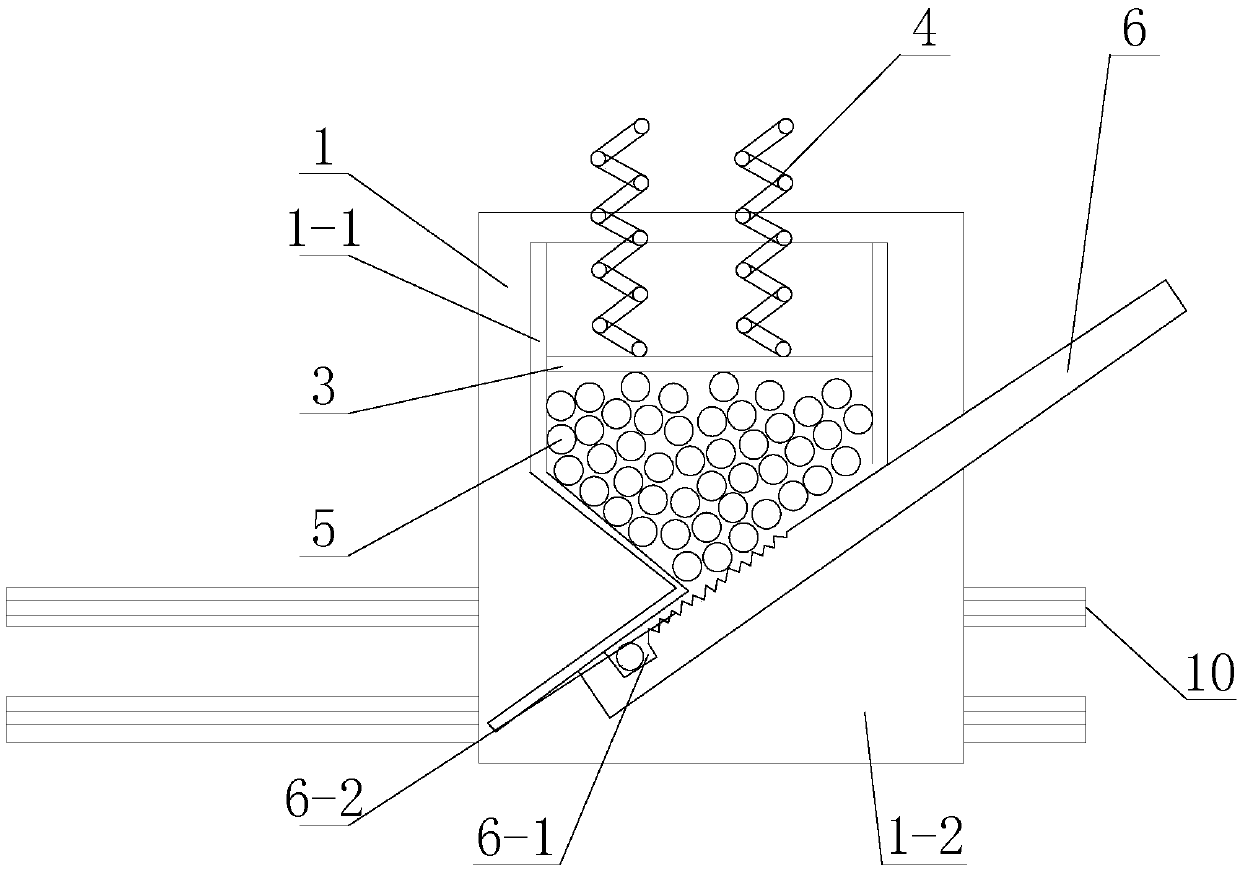

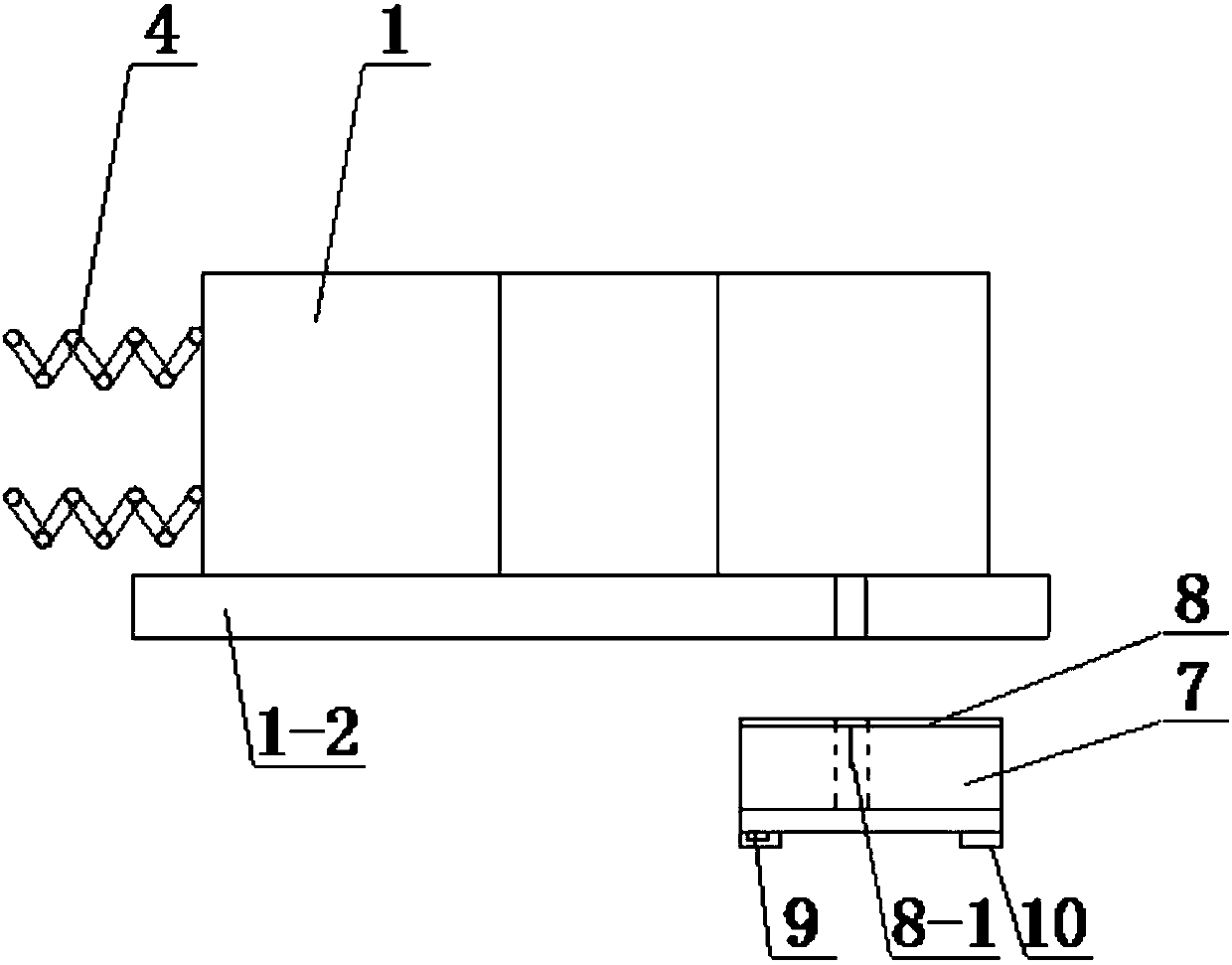

[0020] Specific implementation mode one: combine Figure 1 to Figure 5 To illustrate this embodiment, a device for the pillar planting process of copper pillar grid array interconnection devices described in this embodiment includes a drill chuck translational movement mechanism, a drill chuck rotational movement assembly, a stage assembly, and a feeding assembly. The drill chuck rotary motion assembly is installed on the drill chuck translational motion mechanism, the drill chuck rotary motion assembly is arranged above the stage assembly, and the feeding assembly is arranged on the drill chuck The head turns to one side of the motion assembly. The automatic separation of a single copper column, the flux coating at the end of the copper column and the continuous automatic delivery of the copper column to the designated position are realized through the feeding assembly; The orderly movement of the stage assembly realizes the clamping action of the copper pillar at the specif...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination Figure 4 Describe this embodiment mode. The drill chuck rotation movement assembly of a device used for the pillar planting process of copper pillar grid array interconnection devices described in this embodiment includes a horizontal connecting plate 24, a numerical control motor 25, a motor tensioning plate 26, Driving wheel 27, driven wheel 28, conveyor belt 29, rotating shaft and drill chuck 30, CNC motor 25 is installed on the horizontal connecting plate 24 through motor tension plate 26, and driving wheel 27 is sleeved on the rotating shaft of CNC motor 25 , the driven wheel 28 is sleeved on the upper end of the rotary shaft 30 where the drill chuck is located, and the driving wheel 27 is connected with the driven wheel 28 through a conveyor belt 29 .

[0022] The numerical control motor 25 drives the driving wheel 27 to rotate, and the driving wheel 27 drives the driven wheel 28 to rotate through the conveyor belt 29...

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 4 To illustrate this embodiment, the drill chuck translational motion mechanism of a device for the pillar planting process of copper pillar grid array interconnection devices described in this embodiment includes a vertical base plate 11, an X-direction motion component, and a Z-direction motion assembly. Motion assembly, the X-direction motion assembly includes X-direction linear guide rail 12, X-direction rack 13, X-direction motion gear 14, CNC motor 15, X-direction motion slider 16 and vertical connecting plate 17, X-direction linear guide rail 12 and the X-direction rack 13 are installed side by side in parallel on the vertical base plate 11 from top to bottom, and the vertical connecting plate 17 is slidingly connected with the X-direction linear guide rail 12 through the X-direction moving slider 16, and the CNC motor 15 can be installed on the On the vertical connection plate 17, the X-direction motion gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com