Storage battery plate group automatic film coating machine

A battery and coating machine technology, applied in secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as low efficiency, easy inhalation of dust by workers, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

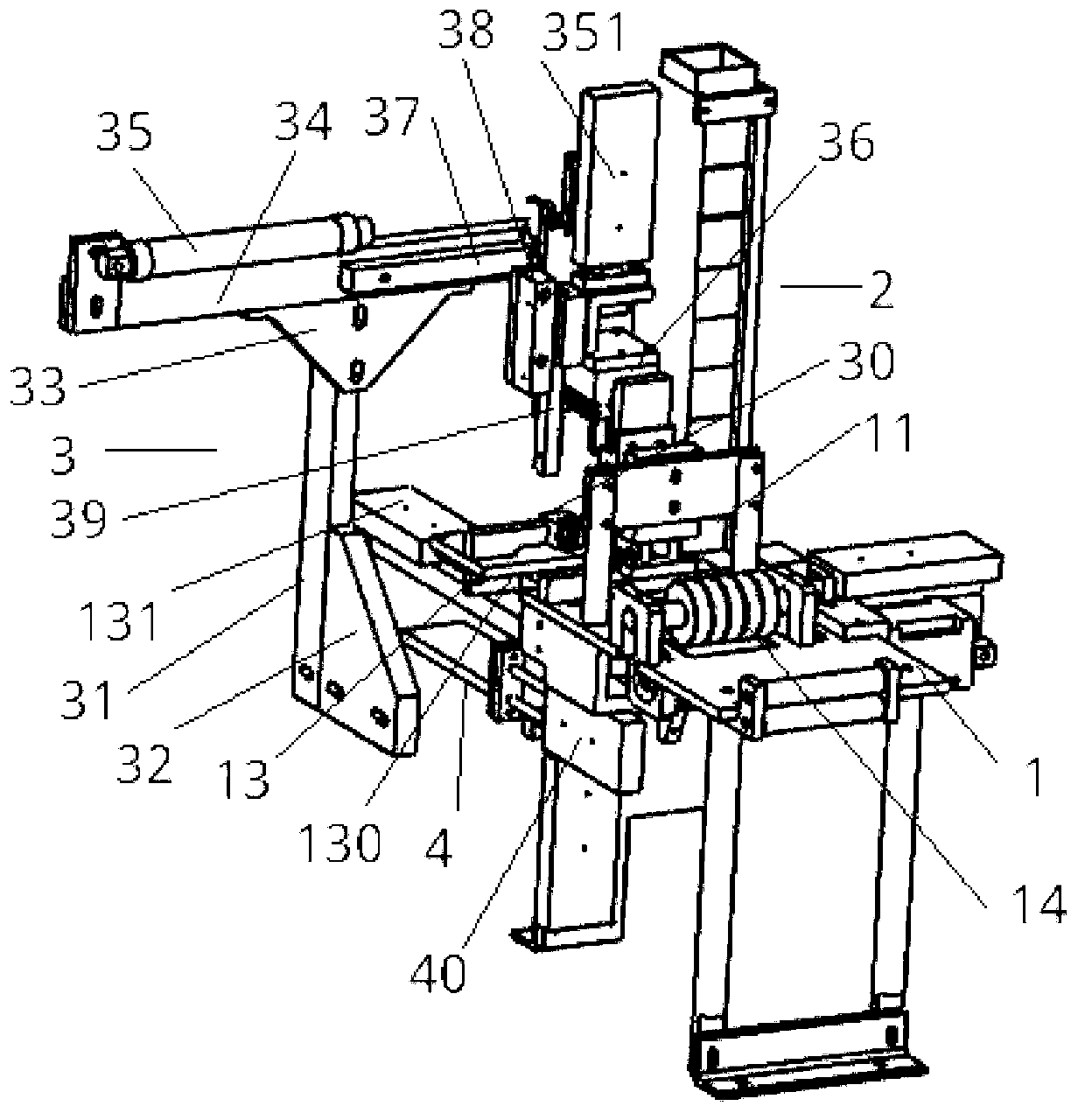

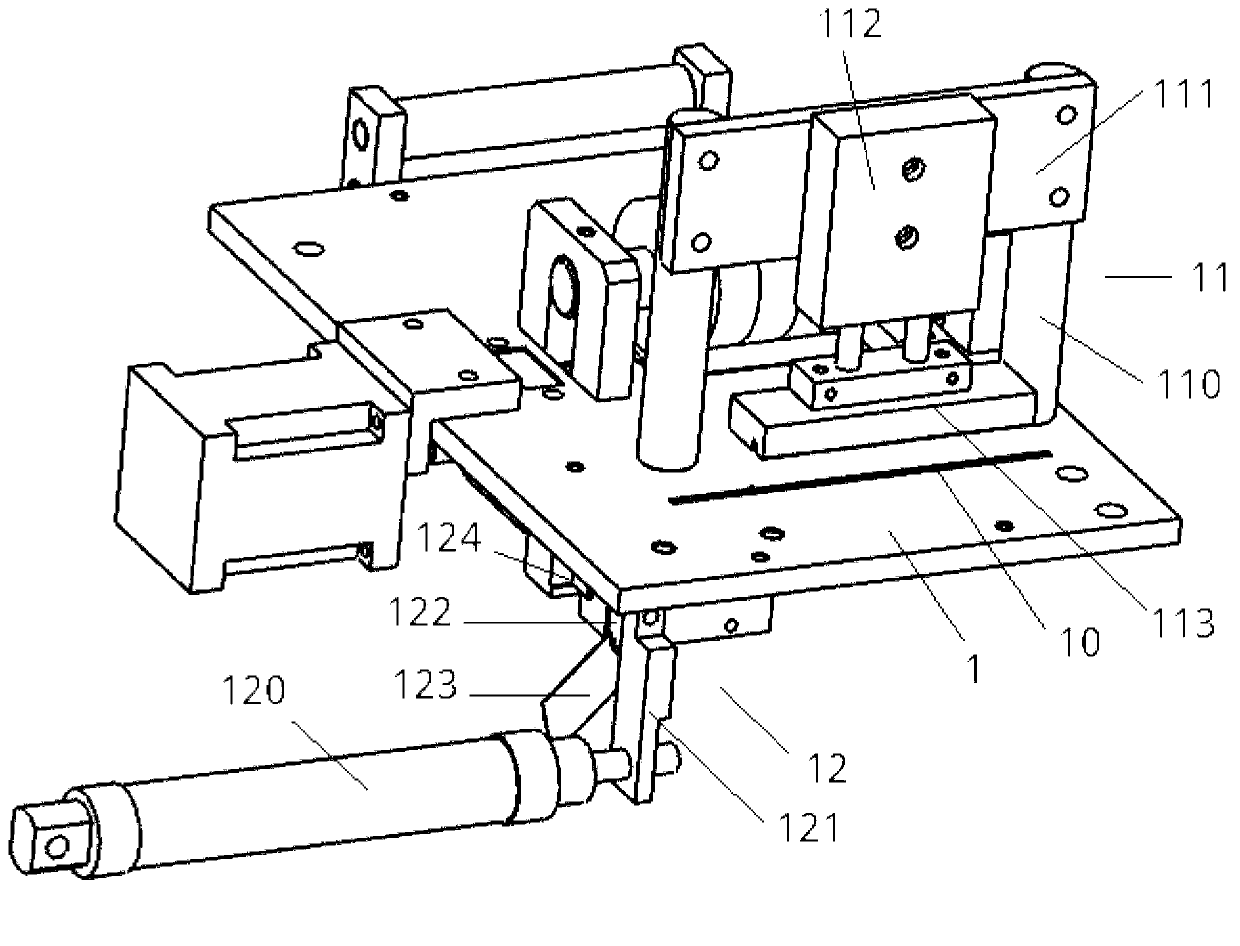

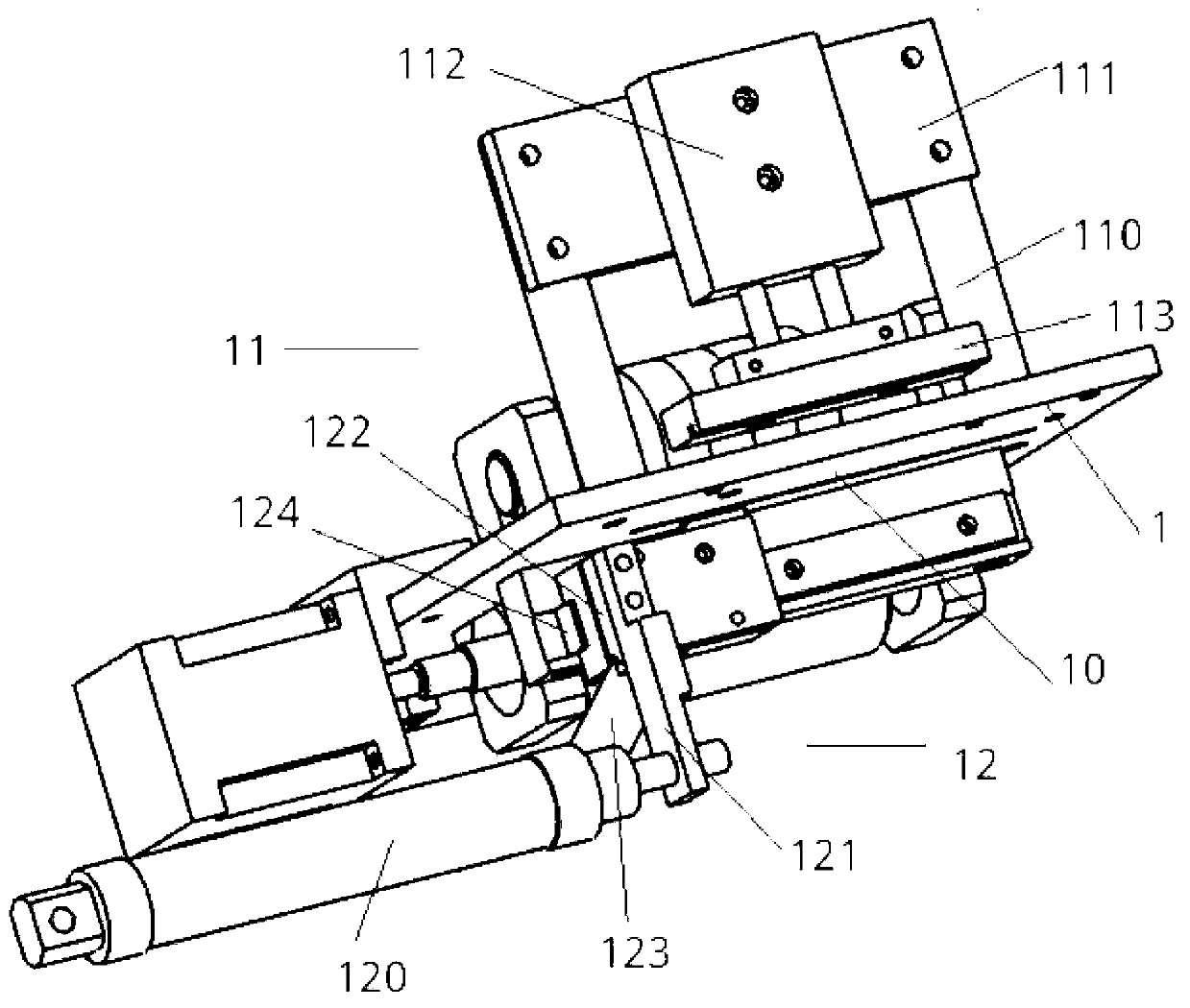

[0021] Combine below Figure 1 to Figure 5 Specifically illustrate the embodiment of battery pole group automatic coating machine, it comprises a horizontal plate 1, and described horizontal plate 1 rear is provided with a rear horizontal plate 13 that is positioned on the same plane with horizontal plate, described horizontal plate 1 and rear horizontal plate 13 are equal in width, and a partition space 130 is provided between the horizontal plate 1 and the rear horizontal plate 13, and the partition space 130 allows the pole group to pass through. The right side of the partition space 130 is provided with the battery box conveying device 2 , the left side of the partition space 130 is provided with the pole group conveying device 3 , and a battery box positioning cylinder 25 is vertically provided directly below the partition space 130 . In addition, the horizontal plate 1 and the rear horizontal plate 13 are provided with a film automatic conveying and cutting device. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com