Tungsten powder surface copper plating method

A tungsten powder and copper plating technology, applied in liquid chemical plating, coating, metal material coating process and other directions, can solve the problems of slow copper plating, uneven plating, and not firm, and improve the plating performance, reduction of coating brittleness and stress, effect of accelerating deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

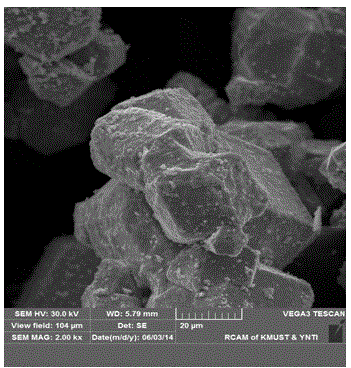

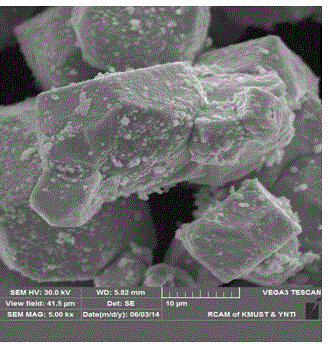

Image

Examples

Embodiment 1

[0029] The method for copper plating on the surface of the tungsten powder comprises the following steps:

[0030] Step 1. First, carry out surface pretreatment on the tungsten powder. The particle size of the tungsten powder is 7 μm. Ultrasonic waves are applied during the pretreatment process. The frequency of the ultrasonic waves is 20KHz, and the unit power factor range is 0.5W / cm 2 , the specific operation of tungsten powder surface pretreatment is as follows:

[0031] (1) Degreasing: put the tungsten powder in 10wt.% sodium hydroxide solution and boil for 10 minutes according to the liquid-solid ratio of 1:30l / g, so that the oil and alkali can fully undergo saponification reaction, filter and wash twice with distilled water;

[0032] (2) Coarsening: Boil the degreased tungsten powder in 30wt.% nitric acid for 20 minutes according to the liquid-solid ratio of 1:30l / g, and wash it twice with distilled water after filtering;

[0033] (3) Sensitization: SnCl 2 2H 2 O and ...

Embodiment 2

[0040] The method for copper plating on the surface of the tungsten powder comprises the following steps:

[0041] Step 1. First, carry out surface pretreatment on the tungsten powder. The particle size of the tungsten powder is 10 μm. Ultrasonic waves are applied during the pretreatment process. The frequency of the ultrasonic waves is 40KHz, and the unit power factor range is 2W / cm 2 , the specific operation of tungsten powder surface pretreatment is as follows:

[0042] (1) Degreasing: put the tungsten powder in 10wt.% sodium hydroxide solution and boil for 10 minutes according to the liquid-solid ratio of 1:100l / g, so that the oil and alkali can fully saponify, filter and wash with distilled water for 3 times;

[0043] (2) Coarsening: Boil the degreased tungsten powder in 30wt.% nitric acid for 30 minutes according to the liquid-solid ratio of 1:100l / g, filter and wash with distilled water for 3 times;

[0044] (3) Sensitization: SnCl 2 2H 2 O and HCl solution are mixed...

Embodiment 3

[0051] The method for copper plating on the surface of the tungsten powder comprises the following steps:

[0052] Step 1. First, carry out surface pretreatment on the tungsten powder. The particle size of the tungsten powder is 8 μm. Ultrasonic waves are applied during the pretreatment process. The frequency of the ultrasonic waves is 30KHz, and the unit power factor range is 1.5W / cm 2 , the specific operation of tungsten powder surface pretreatment is as follows:

[0053] (1) Degreasing: put the tungsten powder in 10wt.% sodium hydroxide solution and boil for 10 minutes according to the liquid-solid ratio of 1:60l / g, so that the oil and alkali can fully saponify, filter and wash twice with distilled water;

[0054] (2) Coarsening: Boil the degreased tungsten powder in 30wt.% nitric acid for 20 minutes according to the liquid-solid ratio of 1:60l / g, and wash it twice with distilled water after filtering;

[0055] (3) Sensitization: SnCl 2 2H 2 O and HCl solution are mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com