Rotation type quantitative spraying equipment

A spraying equipment and rotary technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problem that the sealing agent cannot be completely coated on the surface of the battery steel case, the overall structure of the equipment is complicated, and the synchronization control is difficult and other problems, to achieve the effect of improving the uniformity of spraying, improving the quality of spraying, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

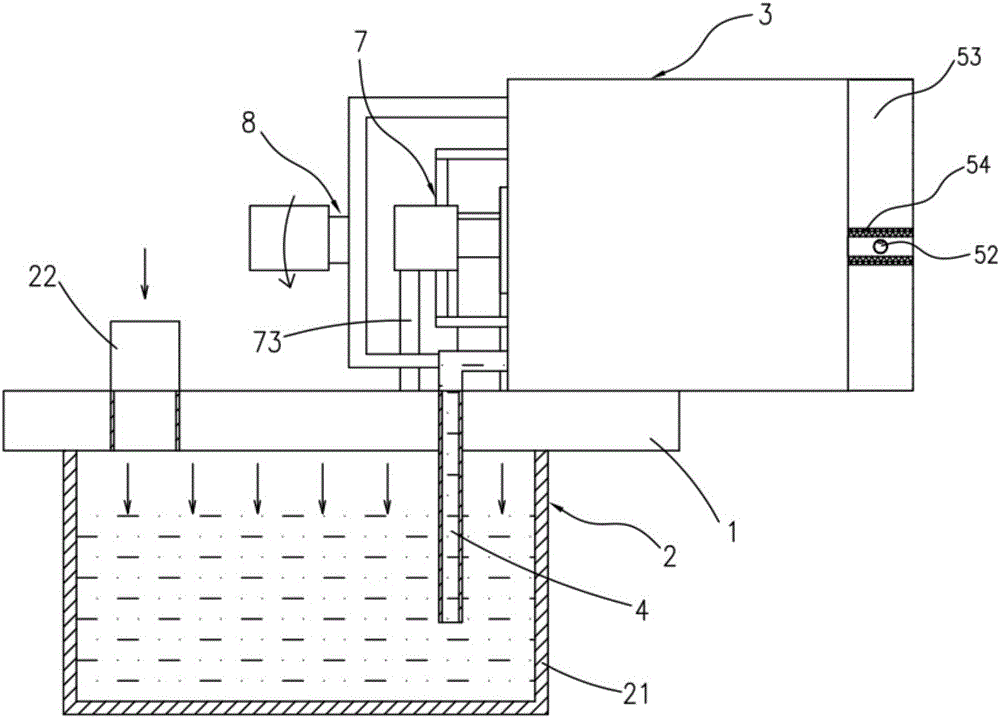

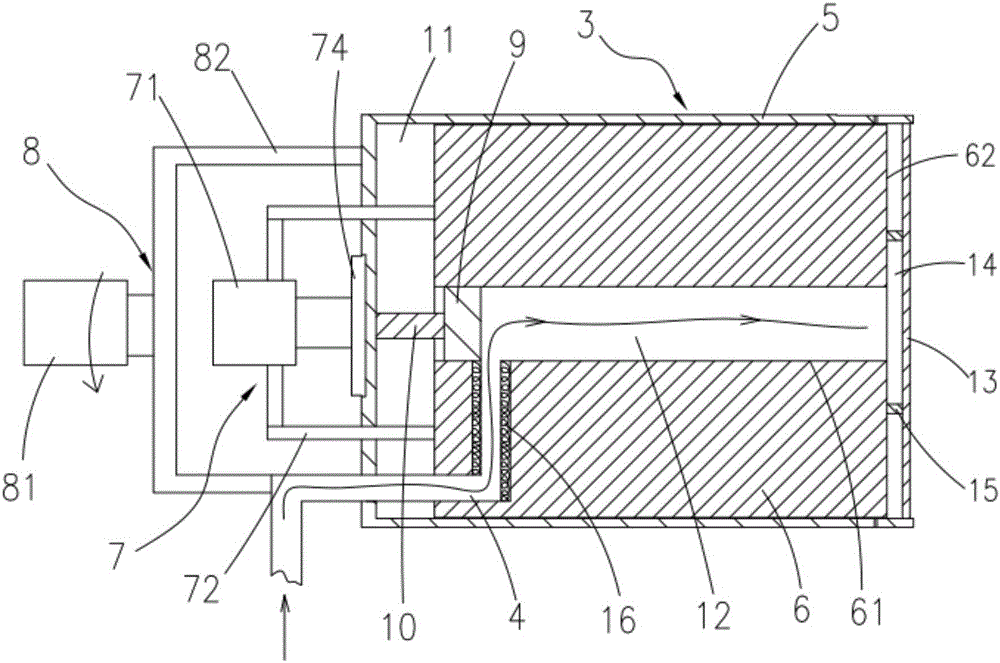

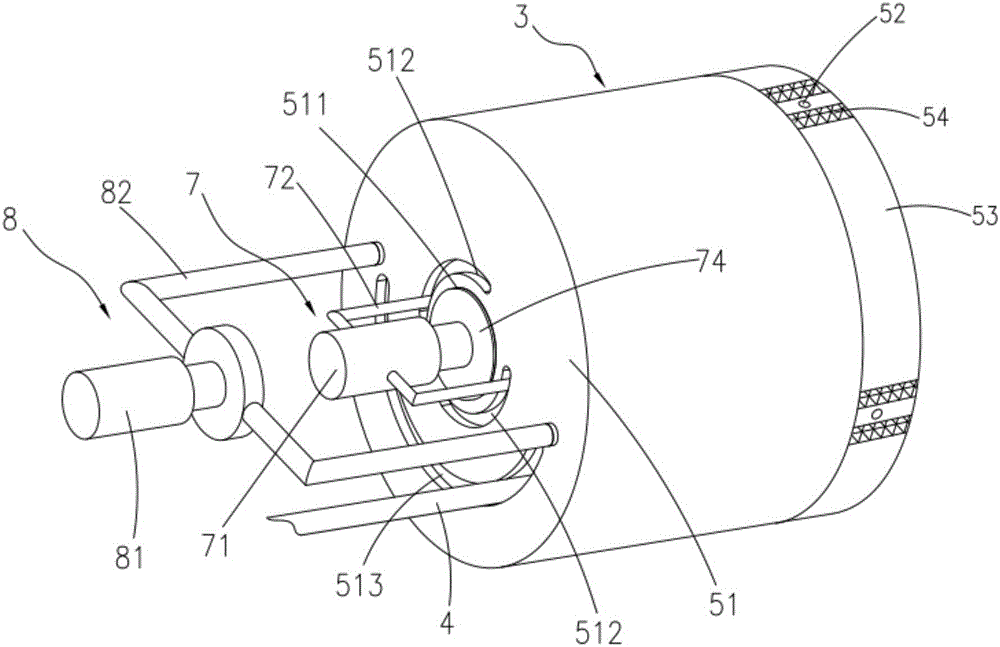

[0033] Such as figure 1 As shown, the present invention provides a rotary quantitative spraying equipment, including a spraying frame 1, a conveying mechanism 2 installed under the spraying frame 1 for automatically adjusting the flow rate of the sealing agent and installed above the spraying frame 1 for the battery steel shell A rotatable nozzle 3 for spraying the sealant, and the conveying mechanism 2 communicates with the nozzle 3 through the agent tube 4, such as figure 2 As shown, the spray head 3 includes a spray cover 5 whose outer diameter is compatible with the inner diameter of the battery steel case and a spray tank 6 placed in the cavity of the spray cover 5. 6. The transmission mechanism 7 that moves left and right and the rotation mechanism 8 that drives the spray cover 5 to rotate 90° around its axis relative to the agent cylinder 6. The rotation mechanism 8 is fixedly arranged on the rear end cover 51 of the spray cover 5. The transmission mechanism 7 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com