Rebar powder coating and production technology thereof

A technology for powder coatings and steel bars, applied in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of non-continuous coating, accelerated corrosion, long curing time, etc., and achieve strong economic and social effects, production Simple process and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

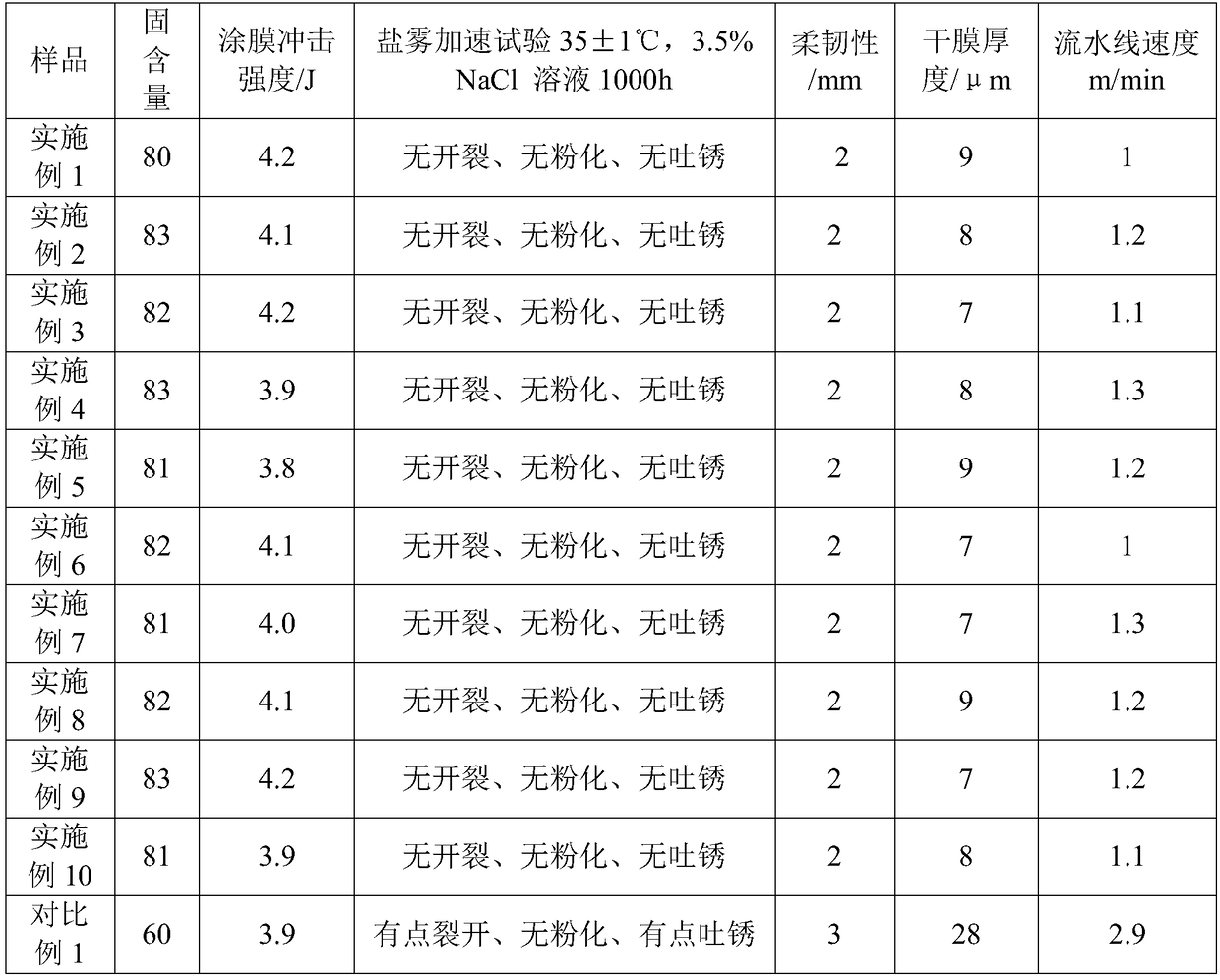

Examples

Embodiment 1

[0029] A kind of production technology of reinforcing steel powder coating comprises the steps:

[0030] 65g polyester resin, 3.5g novolac epoxy resin, 12.5g polytetrafluoroethylene, 0.7g ethyltriphenylphosphine bromide and 18.3g wollastonite were mixed uniformly to obtain a mixture;

[0031] Pour the mixture into the extruder to melt, extrude the coating and press it into tablets. The screw speed of the extruder is 48Hz / min, the feeding speed of the extruder is 23Hz / min, and the temperature of the pre-extrusion zone of the extruder is 98°C , the temperature in the back zone is 102°C;

[0032] Put the paint tablet into a pulverizer for pulverization, the particle size of the pulverized coating is 38 μm, and the finished steel powder coating is obtained, wherein, the speed of the grinding knife in the pulverizer is 42Hz / min, and the pulverizer The rotational speed of the feed screw was 22 Hz / min.

Embodiment 2

[0034] A kind of production technology of reinforcing steel powder coating comprises the steps:

[0035] 64g polyester resin, 5.5g novolac epoxy resin, 12.5g polytetrafluoroethylene, 0.7g ethyltriphenylphosphine bromide and 17.3g wollastonite were mixed uniformly to obtain a mixture;

[0036]Pour the mixture into the extruder to melt, extrude the coating and press it into tablets. The screw speed of the extruder is 48Hz / min, the feeding speed of the extruder is 23Hz / min, and the temperature of the pre-extrusion zone of the extruder is 97°C , the temperature in the back zone is 103°C;

[0037] Put the paint tablet into a pulverizer for pulverization, the particle size of the pulverized coating is 37 μm, and the finished steel powder coating is obtained, wherein, the rotational speed of the grinding knife in the pulverizer is 43Hz / min, and the pulverizer The rotational speed of the feed screw was 23 Hz / min.

Embodiment 3

[0039] A kind of production technology of reinforcing steel powder coating comprises the steps:

[0040] 61g polyester resin, 8.3g novolac epoxy resin, 12.5g polytetrafluoroethylene, 0.7g ethyltriphenylphosphine bromide and 17.3g wollastonite were mixed uniformly to obtain a mixture;

[0041] Pour the mixture into the extruder to melt, extrude the coating and press it into tablets. The screw speed of the extruder is 48Hz / min, the feeding speed of the extruder is 23Hz / min, and the temperature of the pre-extrusion zone of the extruder is 97.5°C , the temperature in the back zone is 102.5°C;

[0042] Put the paint tablet into a pulverizer for pulverization, the particle size of the pulverized coating is 39 μm, and the finished steel powder coating is obtained, wherein, the speed of the grinding knife in the pulverizer is 42Hz / min, and the pulverizer The rotational speed of the feed screw was 23 Hz / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com