Drum-type film coating equipment

A kind of coating equipment, drum-type technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of high equipment cost, low efficiency, difficult to guarantee the coating quality, etc., achieve continuous coating, ensure coating quality, improve Effect of Coating Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

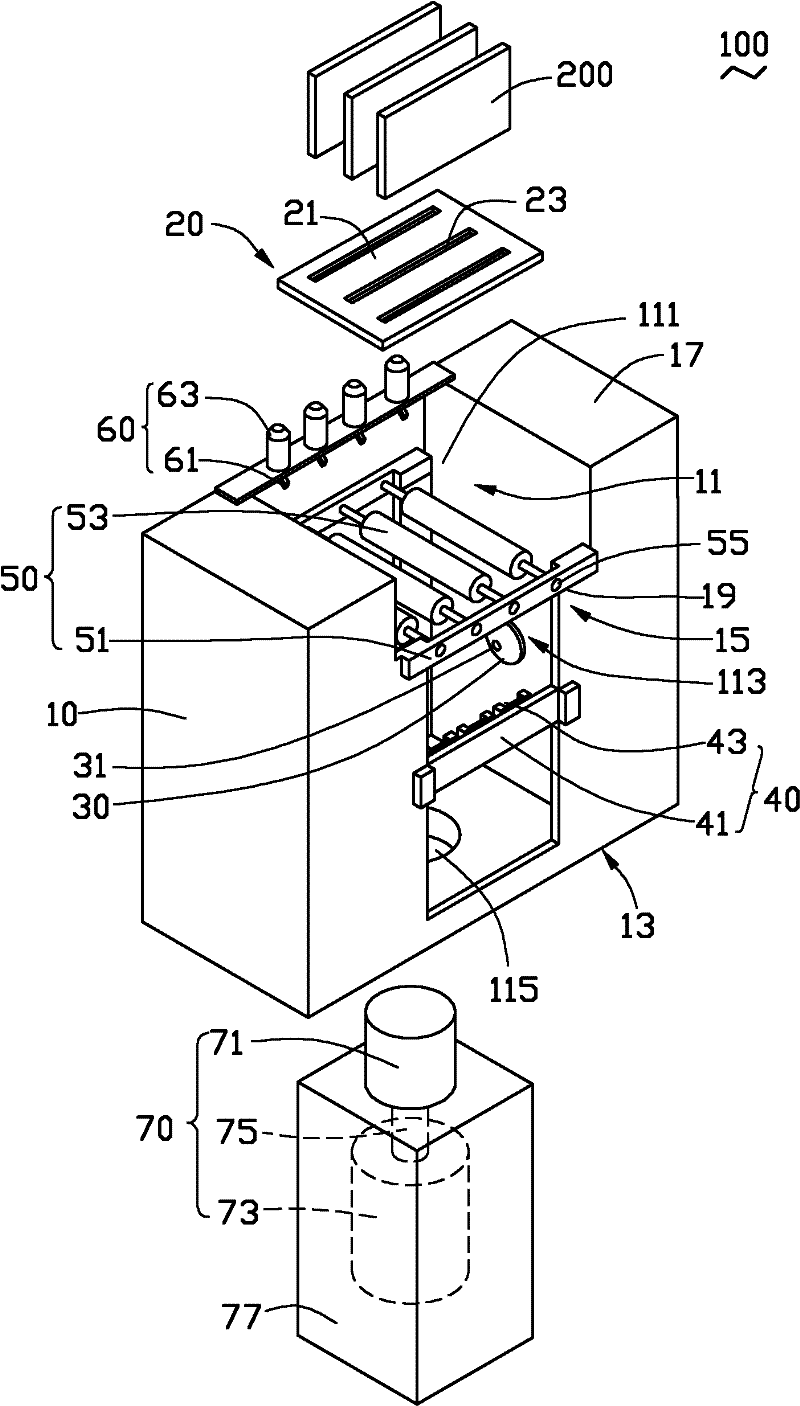

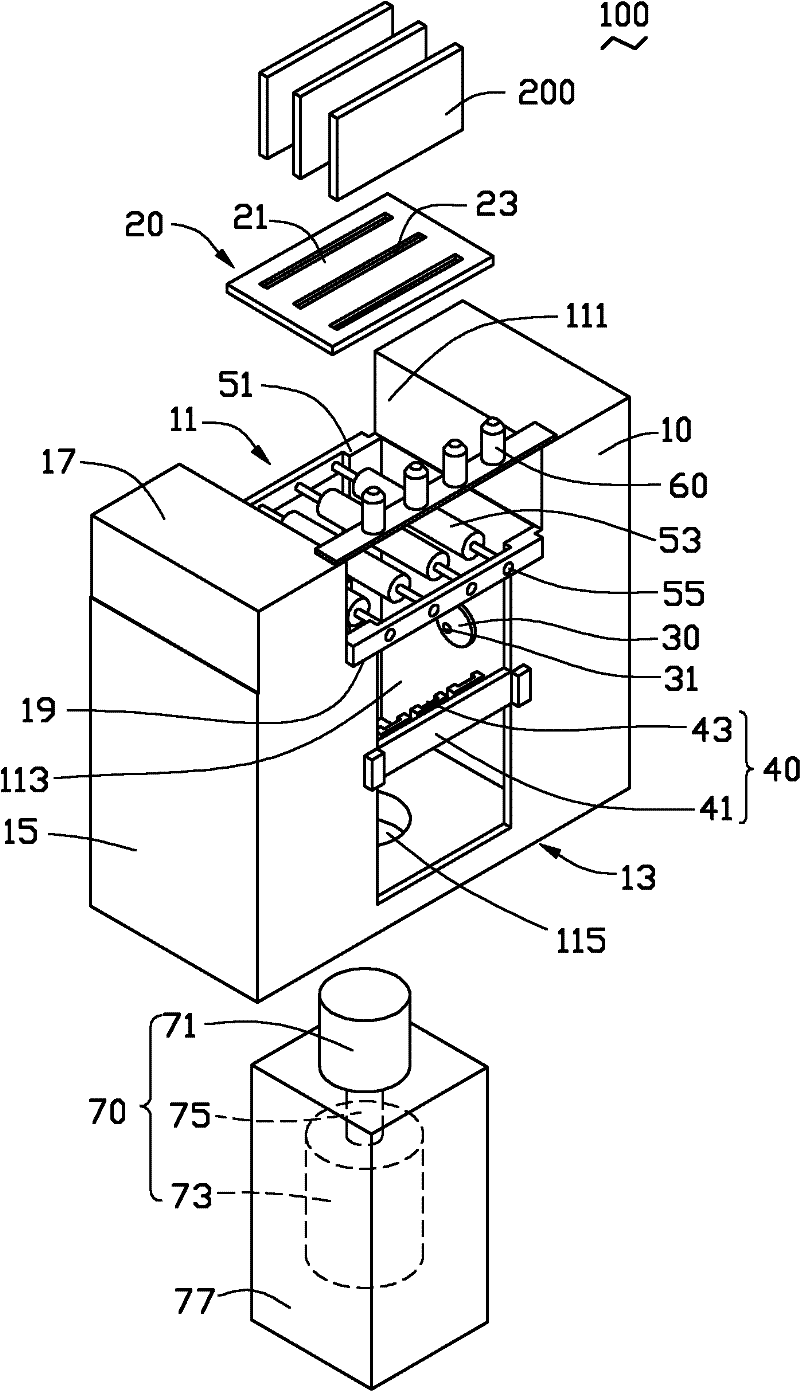

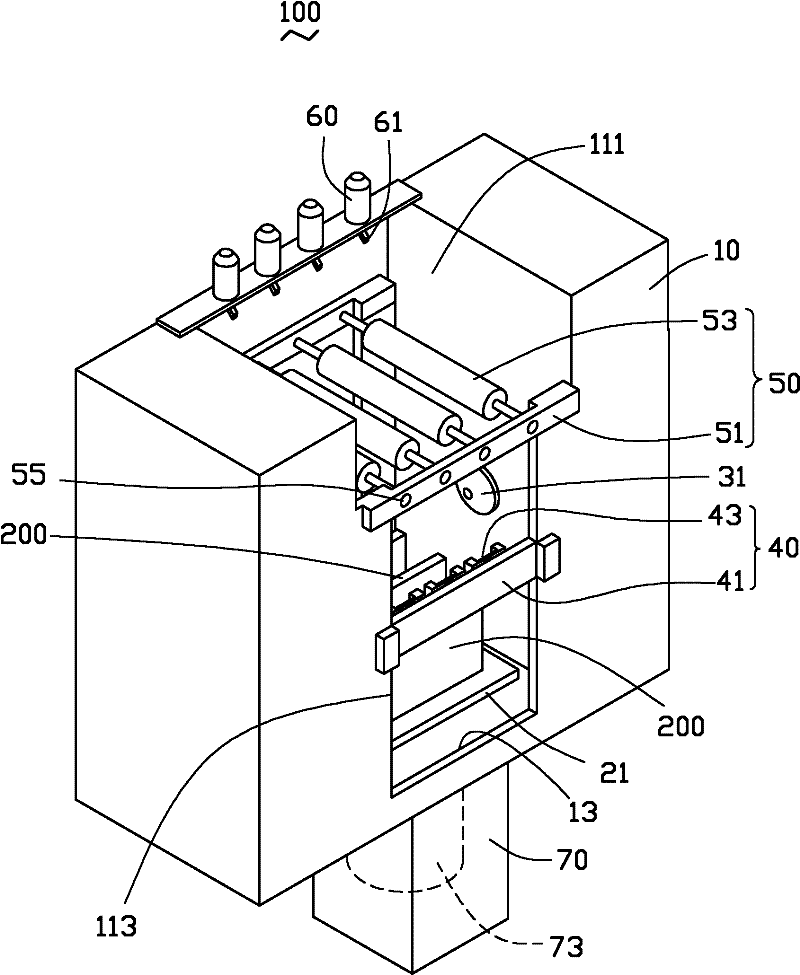

[0044] see figure 1 with figure 2 , a drum-type coating device 100 provided in a preferred embodiment of the present invention, which includes a carrying device 10 , and the carrying device 10 is formed with a receiving tank 11 . The drum coating equipment 100 also includes a base 20 arranged at the bottom of the storage tank 11, a cleaning device 30 and a heating device 40 arranged at the middle of the storage tank 11, a roller device 50 arranged at the top of the storage tank 11, and A liquid spraying device 60 above the roller device 50 and a driving device 70 arranged at the bottom of the carrier device 10 . The base 20 is used to support at least one substrate to be coated 200, and the driving device 70 drives the base 20 to drive the substrate to be coated 200 to move up and down in the storage tank 11 for the roller device 50 and the liquid spraying device 60 together to coat the substrate 200 to be coated.

[0045] Specifically, the carrying device 10 includes a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com