Chamber type leaves-storing process for tobacco processing line

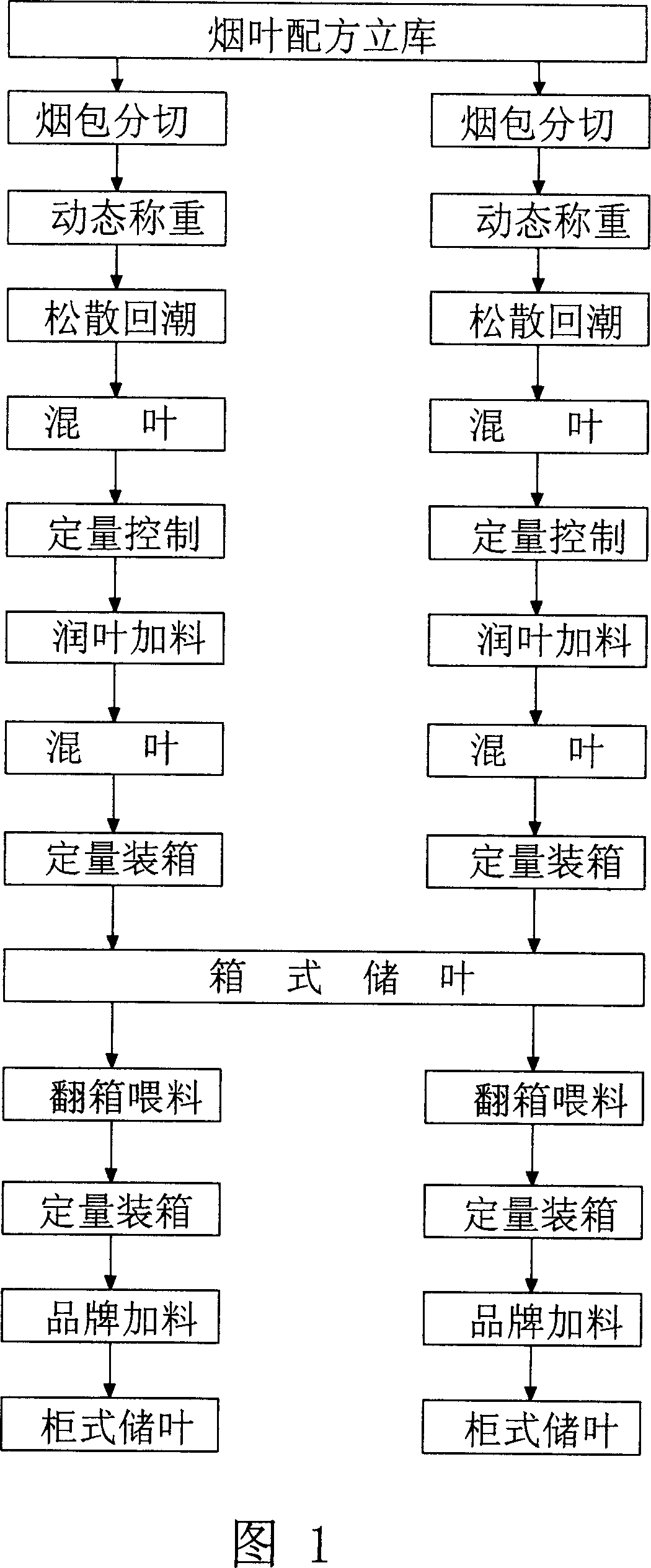

A tobacco manufacturing and process technology, which is applied in the field of box-type leaf storage technology, can solve the problems of complex operability control system, excessively long auxiliary equipment length, restricting formula scalability, etc., so as to reduce the complexity of equipment layout and control. performance, improve the effective utilization rate, and the effect of easy equipment control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment one, 1650kg / h production line application example (referring to Fig. 4)

[0026] Experimental material

[0027] A certain brand of first-class cigarettes from Kunming Cigarette Factory of Hongyun Group was selected as the test object, and it was produced on a 1650kg / h production line, with a batch of 1800kg. The brand is divided into three modules, A, B, and C, and its processing requirements are shown in Table 1:

[0028] module name

Module size (kg)

Storage time (h)

A

600

8

B

600

16

C

600

24

[0029] The three modules of tobacco leaves are packed and stored in boxes, and the box storage method adopts the form of a vertical warehouse, as shown in Figure 4.

[0030] Production process steps:

[0031] 1. Tobacco leaves of module C (modules with long storage time are produced first to ensure storage time) after leaf pretreatment 28 and primary feeding 29,...

Embodiment 2

[0035] Embodiment two, 5500kg / h production line application example (referring to Fig. 5)

[0036] Experimental material

[0037] A brand of second-class cigarettes from Kunming Cigarette Factory of Hongyun Group was selected as the test object, and it was produced on a 5500kg / h production line, with a batch of 6000kg. The brand is divided into three modules, A and B, and its processing requirements are shown in Table 2:

[0038] module name

Module size (kg)

Storage time (h)

A

3000

2

B

3000

4

[0039] The tobacco leaves of the two modules are filled and stored in boxes, and the box storage method adopts the form of a flat warehouse, as shown in Figure 5.

[0040] Production process steps:

[0041] 1. Tobacco leaves of module B (modules with long storage time are produced first to ensure storage time) after leaf pretreatment 43 and primary feeding 44, enter the leaf mixing cabinet 45 for mixing, so...

Embodiment 3

[0044] Embodiment three, 12000kg / h production line application example (referring to Fig. 6)

[0045] Experimental material

[0046] A brand of third-class cigarettes produced by Hongyun Group Kunming Cigarettes was selected as the test object, and it was produced on a 12,000kg / h production line. The whole batch was fed 12,000kg, and the storage time was 1 hour.

[0047] The tobacco leaves of this brand are packed and stored in boxes after feeding, and the box storage method adopts the conveyor form, as shown in Figure 6.

[0048] Production process steps:

[0049] 1. After the tobacco leaves are subjected to leaf pretreatment 54 and primary feeding 55, they enter the leaf mixing cabinet 56 for mixing, and after mixing evenly, they come out of the cabinet, are measured by an electronic scale 57, and then enter the case packing machine 58 for packing and capping, and the tobacco leaves are filled. Case is conveyed by conveyor, automatic shuttle car 59, puts into storage on a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com