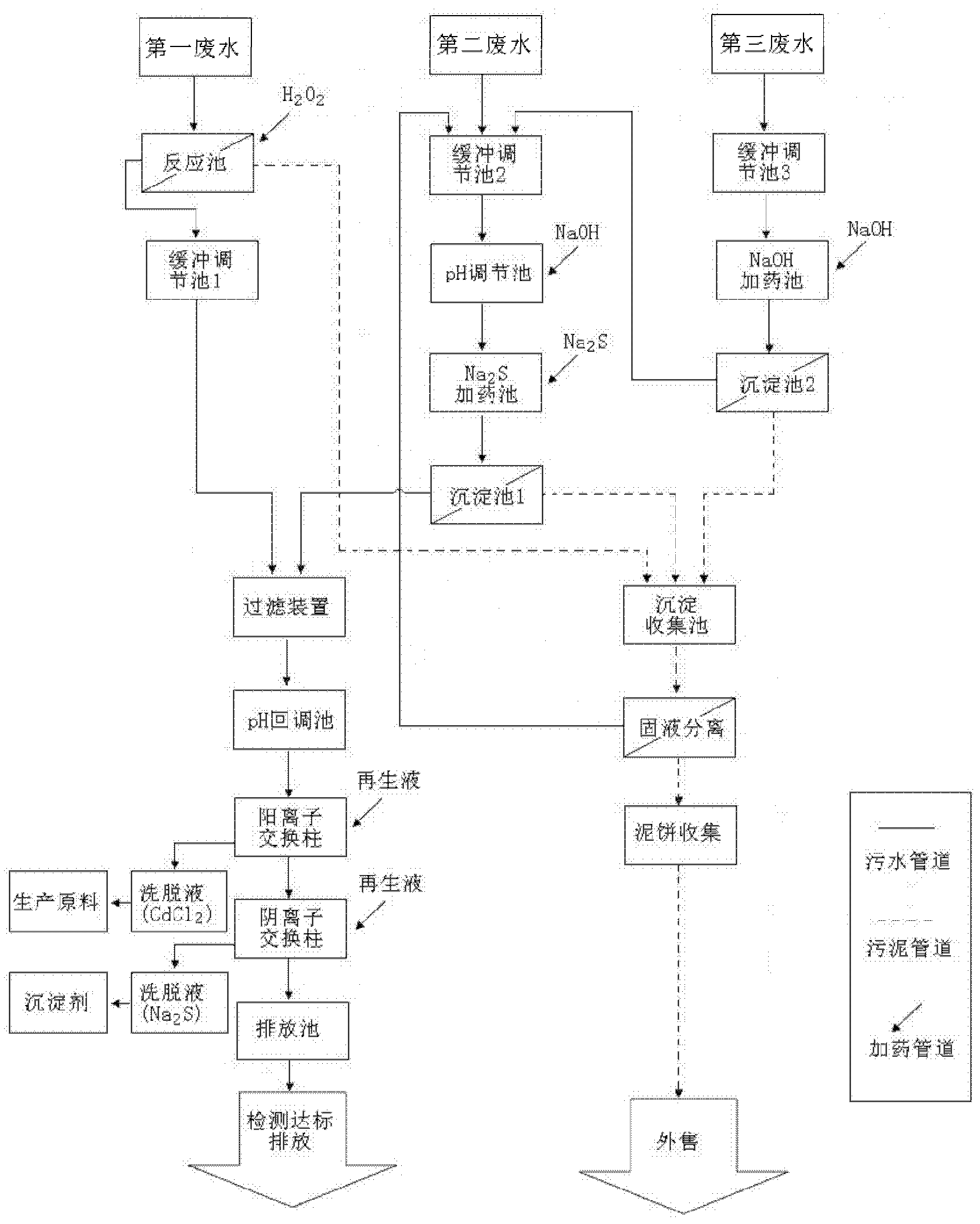

Cadmium-containing wastewater treatment method

A treatment method and wastewater technology, which are applied in the fields of energy wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of inability to recycle cadmium, high operating costs, frequent regeneration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Get the first cadmium-containing wastewater 200mL, adjust the pH value to 8.0, add 0.067mL of 30% H 2 o 2 , so that the concentration is 0.01%, the reaction temperature is controlled at 35°C, and the precipitate settles naturally. After settling wastewater, the supernatant was filtered and the pH was adjusted back to 7.0 with hydrochloric acid, and then passed through the 50cm long at a flow rate of 5ml / min. The anion and cation exchange column is filled with large pore size styrene-based cation exchange resin and strong basic quaternary ammonium type I anion exchange resin respectively. The cadmium content in the effluent is 0.0126mg / L.

[0053] Take 200mL of the second waste water, adjust the pH value to 8.5 with NaOH, add Na under stirring 2 S, sedimentation and natural settlement. After settling wastewater, the supernatant was filtered and the pH was adjusted back to 7.0 with hydrochloric acid, and then passed through the 50cm long at a flow rate of 5ml / min. T...

Embodiment 2

[0056] Take the first cadmium-containing wastewater 1800L, adjust the pH value to 8.5, add 1.2L of 30% H 2 o 2 , so that H in the wastewater after adjustment 2 o 2 The concentration is 0.02%, the reaction temperature is controlled at 40°C, and the precipitate settles naturally. After settling wastewater, the supernatant was filtered and the pH was adjusted back to 7.0 with hydrochloric acid, and then passed through the 50cm long at a flow rate of 25ml / min. The anion and cation exchange column is filled with large pore size polystyrene cation exchange resin and strong basic quaternary amine type I anion exchange resin respectively. The cadmium content in the effluent is 0.0039mg / L, and the sulfur content is not detected.

[0057] Get the second waste water 1800L, adjust the pH value to 8.5 with NaOH, add Na under stirring 2 S, sedimentation and natural settlement. After settling wastewater, the supernatant was filtered and the pH was adjusted back to 7.0 with hydrochloric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com