Catalyst for treating waste water, method for preparing the same and process for treating waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1 to 5

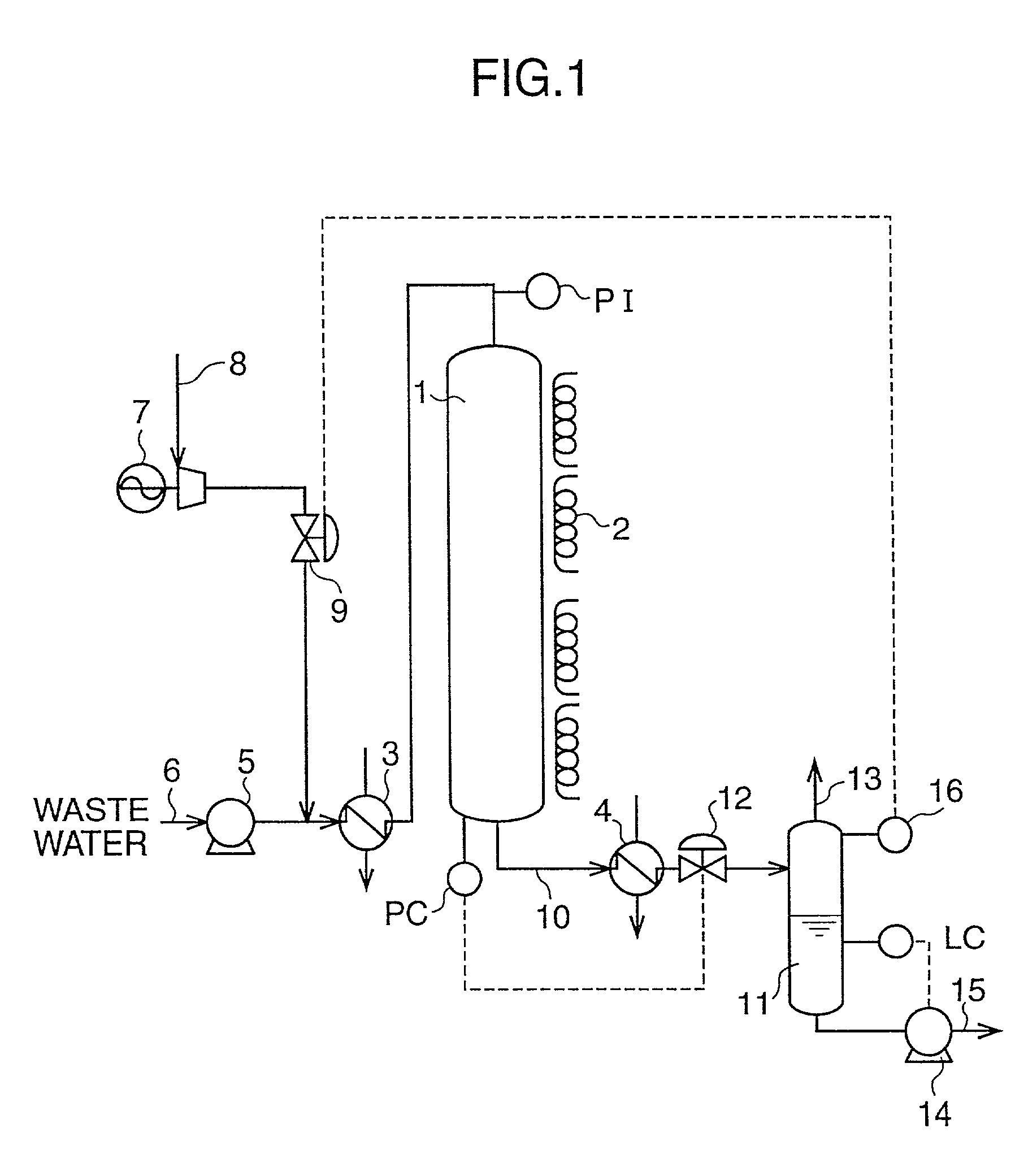

[0160] 500 hours of waste water treatment was performed under the following conditions with using the equipment illustrated in FIG. 1. A reactor 1 having cylindrical shape (a diameter of 26 mm.phi. and a length of 3000 mm) was used in the treatment. Into the reactor, loaded were 1 liter (380 g) of pellet type solid catalysts having a diameter of 4 mm .phi. to give a catalyst bed height of 1880 mmH. The solid catalyst had activated carbon and platinum as main components and included 0.3 mass % of platinum with respect to the total amount of the solid catalyst. In addition, as the waste water to be treated in the present examples, used was waste water exhausted by manufacturing facilities of aliphatic carboxylic acids and aliphatic carboxylate. The waste water contained organic compounds having 2 or more carbon atoms per molecule such as alcohol, aldehyde and carboxylic acid. The COD (Cr) concentration of the waste water was 20000 mg / liter and pH thereof equaled 2.8. In addition, 55% ...

example 6

[0164] The treatment was performed in the same manner including the same catalyst, treatment processes, treatment conditions and equipment as in example 4, except that the treatment temperature was set to 140.degree. C. This result was also shown in table 1. In addition, after 5000-hour treatment, the catalyst was extracted from the reactor to be observed. As a result, it was found that the catalyst in this experiment stayed unchanged after the treatment.

example 7

[0165] The treatment was performed in the same manner including the same catalyst, treatment processes, treatment conditions and equipment as in example 1 except for the following 3 points: 1) the treatment temperature was set to 95.degree. C.; 2) the treatment pressure was set to the atmosphere pressure; and 3) the supply amount of oxygen-containing gas was adjusted to 0.40 in term of O.sub.2 / COD. This result was also shown in table 1. In addition, after 5000-hour treatment, the catalyst was extracted from the reactor to be observed. As a result, it was found that the catalyst in this experiment stayed unchanged after the treatment.

1TABLE 1 COD(Cr) COD(Cr) Treatment Treatment Efficiency Efficiency After Oxygen After 500 Hour Concentration 5000 Hour Treatment In Exhaust Treatment O.sub.2 / COD D Value (%) Gas (vol %) (%) Example 0.75 0.79 77 0 --1 Example 0.85 0.89 86 0 86 2 Example 0.95 1.00 95 0.2 95 3 Example 1.00 1.05 93 1.5 92 4 Example 1.10 1.15 93 3.5 90 5 Example 1.00 1.00 99....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com