Method and equipment for treating sludge in normal state

A sludge, normal technology, applied in the oxidation treatment of sludge, dewatering/drying/concentrated sludge treatment, etc., can solve the problems of insignificant effect, high price, affecting the industrial application and promotion of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

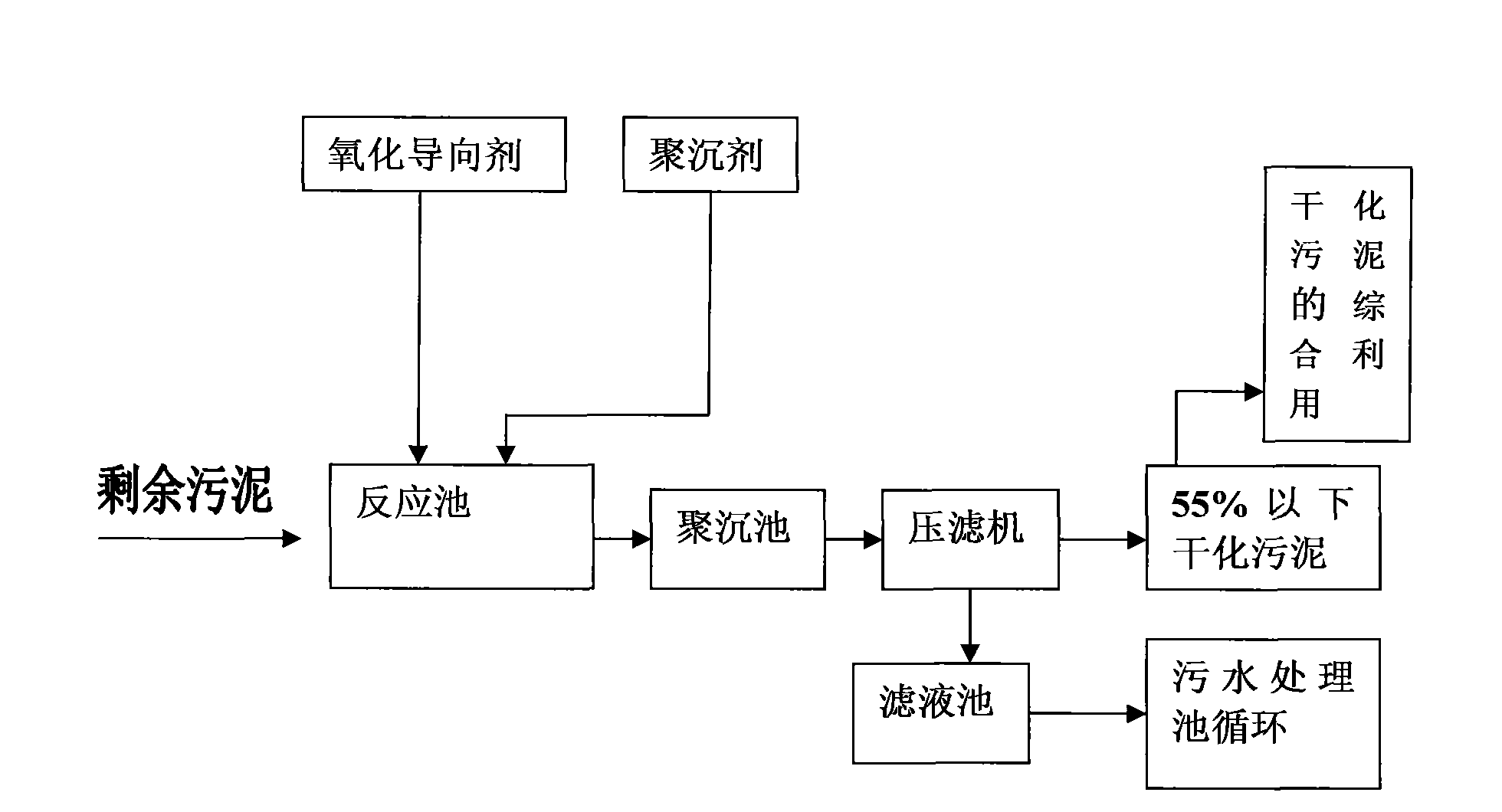

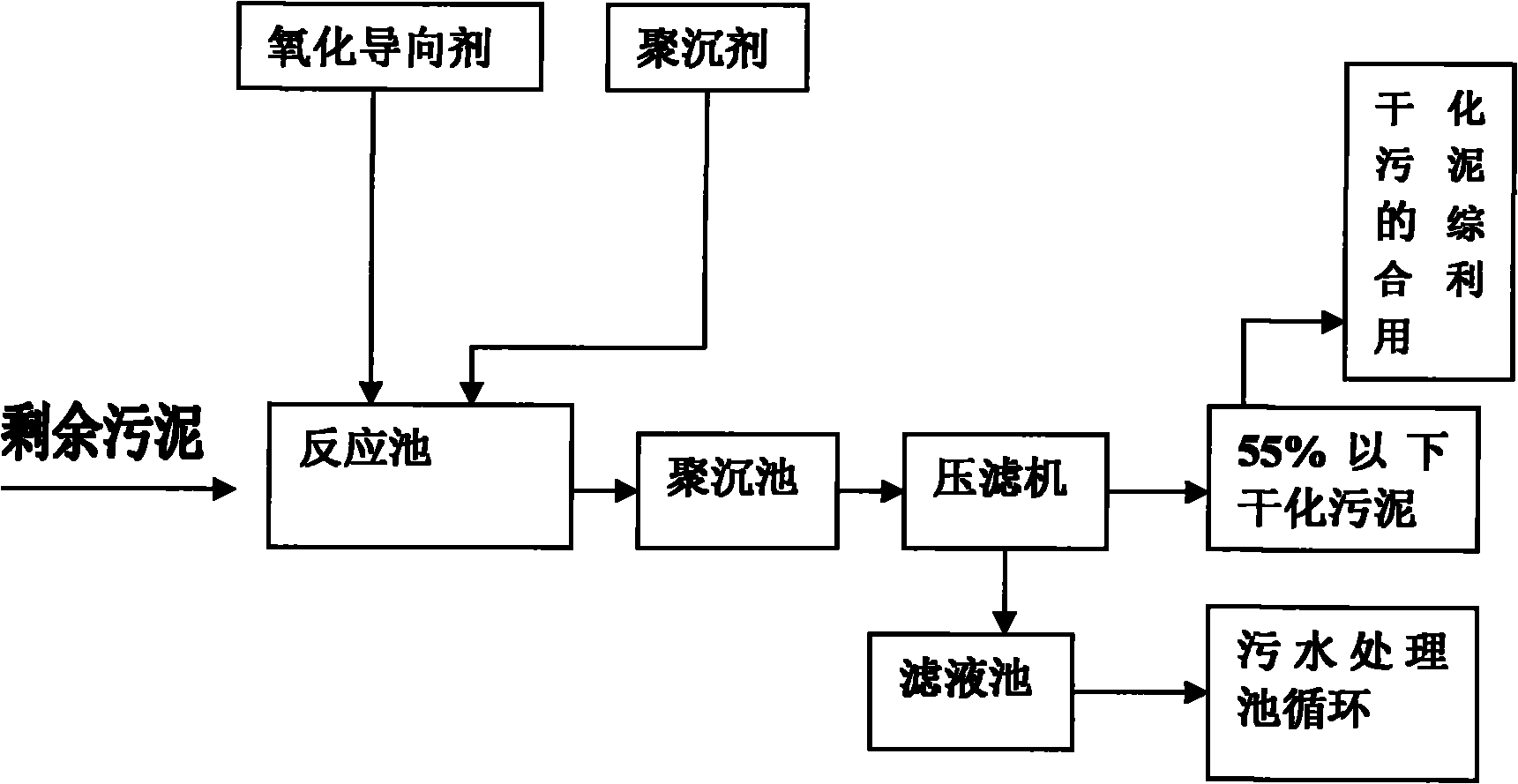

Method used

Image

Examples

Embodiment 1

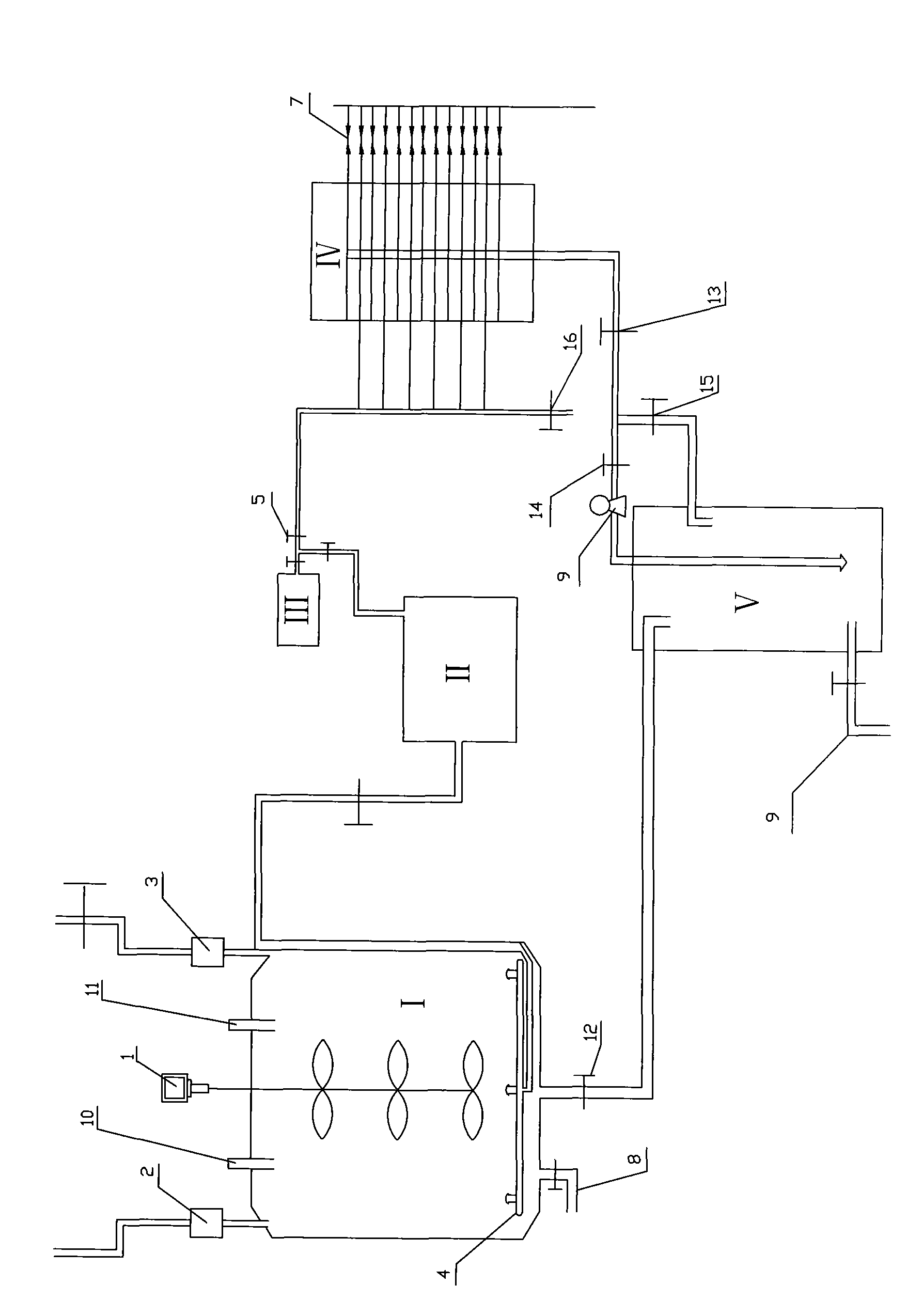

[0024] Such as figure 2 As shown, the sludge treatment equipment provided by the present invention includes a reaction tank I, an ozone generator II, an air compression system III, a filter press system IV and a coagulation tank V. Wherein, the reaction tank 1 is also connected with the agitator 1, the tail gas treatment device 2, the excess sludge feeding device 3, the liquid feed port 10, and the solid feed port 11; Empty pipeline 8, also be provided with the aeration device 4 that is communicated with ozone generator II at the bottom of reaction tank; Press filter system IV communicates with air compression system III, and, by providing oxygen-enriched air to ozone generator II; Settling tank V communicates with press filter system IV through feed pump 9 .

[0025] For operating procedures, see figure 2 :

[0026]1. Close the sludge outlet valve 12 of the reaction tank, open the residual sludge feed device 3 of the reaction tank to feed, and add metered oxidation direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com