TiO2-carrying photoelectric catalyst for photoelectrocatalytic advanced treatment on sludge and method and device for TiO2-carrying photoelectric catalyst-based photoelectrocatalytic advanced treatment on sludge

A photoelectric catalysis and advanced treatment technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the limitation of direct landfill of sludge and comprehensive utilization of resources. , the water content of sludge cannot be reduced, affecting the surrounding ecological environment and other problems, so as to facilitate the application of resources, improve the oxidation effect, and save the treatment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

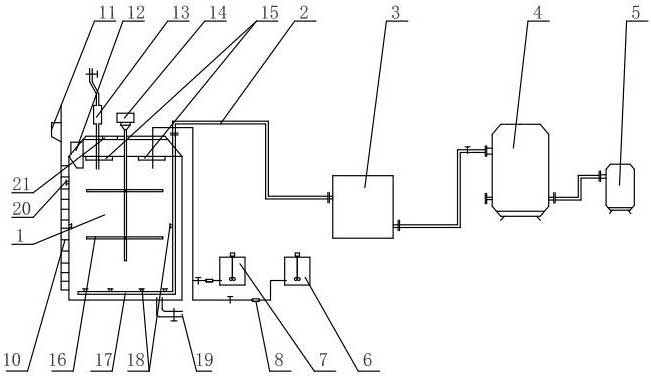

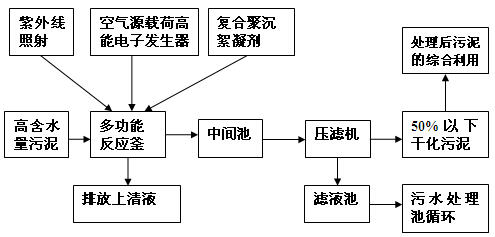

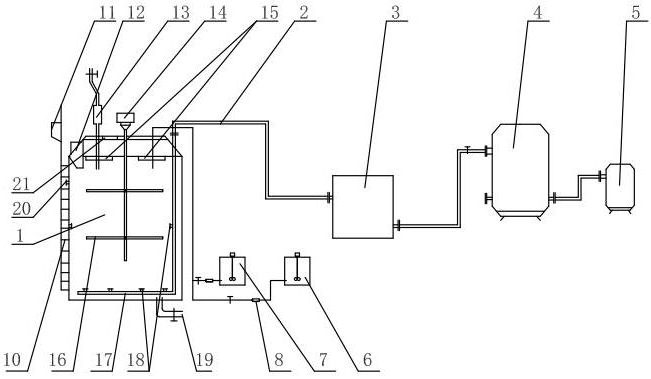

[0046] The excess sludge with a concentration of 15100mg / L and an organic matter content of 32% is introduced into the reactor, and the amount of introduction is 94.3m 3 , and then add loaded TiO in the reactor 2 Photoelectric catalyst (configured according to 0.75 kg of core catalyst and 74.05 kg of carrier), after stirring for 5 minutes, turn on the ultraviolet generator 15 to irradiate the sludge in the reactor, and at the same time introduce high-energy electrons through the aeration pipeline through the high-energy electron generator 3 The reaction was carried out while stirring for 50 min. Then add composite coagulant (PAC14.0kg, PAM1.89kg) through the dispensing tank, and after 5 minutes, discharge the supernatant in the reaction kettle into the drainage system of the sewage treatment plant, discharge the sludge to the intermediate tank, and lift it to the diaphragm through the screw pump Filter press, through ordinary press filtration, sludge with a moisture content o...

Embodiment 2

[0048] The excess sludge with a concentration of 14800mg / L and an organic matter content of 35% is introduced into the reactor, and the amount of introduction is 95.6m 3 , and then add loaded TiO in the reactor 2 Photocatalyst (configured according to 0.98 kg of core catalyst and 64.02 kg of carrier), after stirring for 5 minutes, turn on the ultraviolet generator 15 to irradiate the sludge in the reactor, and at the same time introduce high-energy electrons through the aeration pipeline through the high-energy electron generator 3 The reaction was carried out while stirring for 60 minutes. Then add composite coagulant (PAC16.00kg, PAM1.89kg) through the dispensing tank, and after 5 minutes, discharge the supernatant in the reaction kettle into the drainage system of the sewage treatment plant, discharge the sludge to the intermediate tank, and lift it to the diaphragm through the screw pump Filter press, through ordinary press filtration, sludge with a moisture content of 48...

Embodiment 3

[0050] The remaining sludge with a concentration of 16560mg / L and an organic matter content of 20% is introduced into the reactor, and the amount of introduction is 96.8m 3 , and then add loaded TiO in the reactor 2 Photoelectric catalyst (configured according to 0.26 kg of core catalyst and 51.54 kg of carrier), after stirring for 5 minutes, turn on the ultraviolet generator 15 to irradiate the sludge in the reactor, and at the same time introduce high-energy electrons through the aeration pipeline through the high-energy electron generator 3 The reaction was carried out while stirring for 30 min. Then add composite coagulant (PAC16.86kg, PAM2.18kg) through the dispensing tank, and after 5 minutes, discharge the supernatant in the reaction kettle into the drainage system of the sewage treatment plant, discharge the sludge to the intermediate tank, and lift it to the diaphragm through the screw pump Filter press, through ordinary press filtration, sludge with a moisture conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com