Resource regeneration processing method and equipment for urban sewage sludge

A technology of municipal sludge and treatment method, which is applied in the field of resource treatment of municipal sludge, can solve the problems of high comprehensive cost of sludge treatment and difficulty in achieving economic scale, and achieve perfect design, less material loss and reduced production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

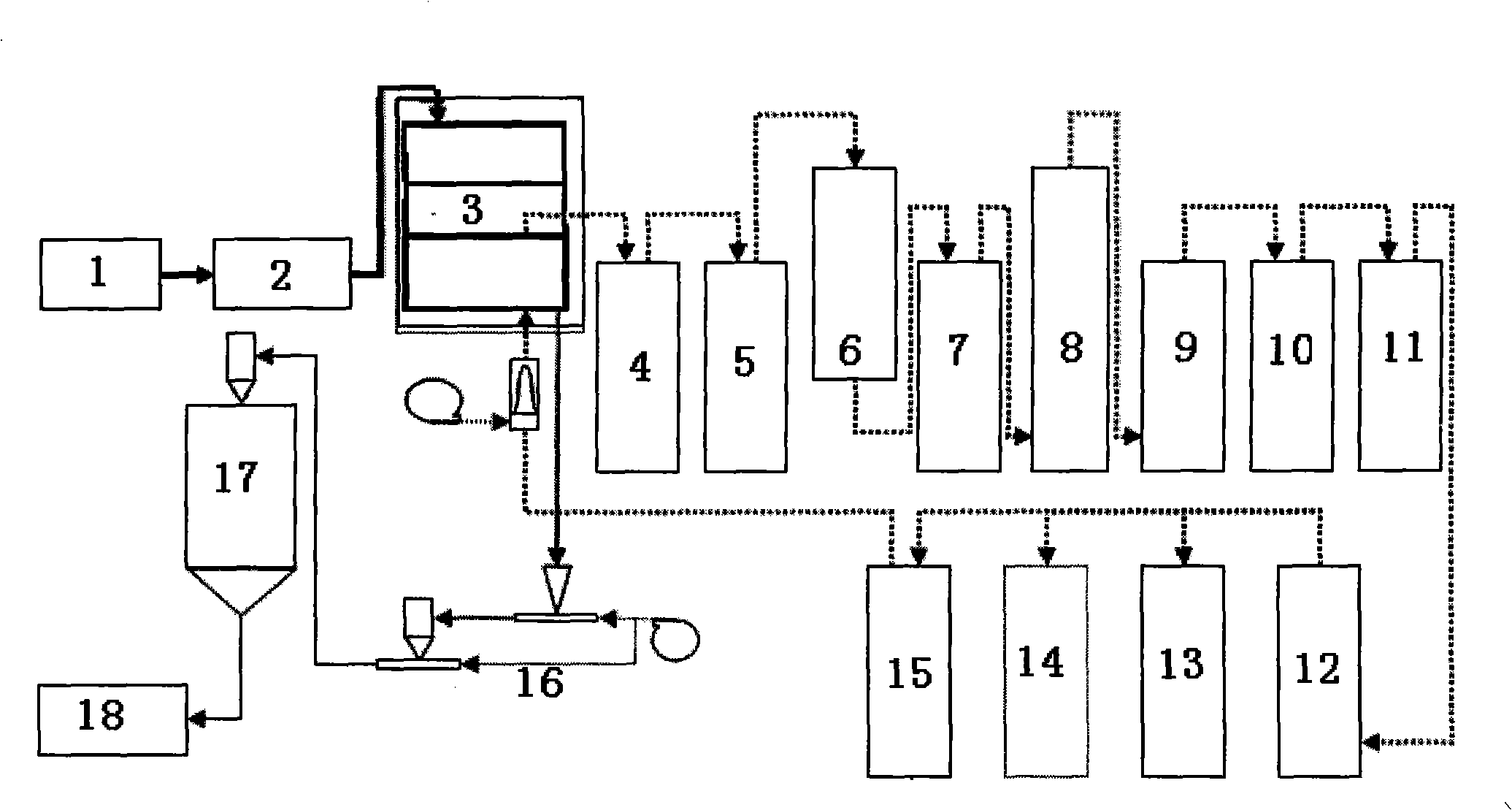

[0011] Example 1: Take dried sludge with an annual treatment capacity of 10,000 tons as an example.

[0012] The processing device of the production line is composed of: electric screen, electronic weighing quantitative feeding system, secondary drying system, combustion chamber, thermal decomposition system: dry distillation pyrolysis furnace (2×5000t / a, single furnace processing capacity>750kg / h) , Star discharger, screw conveyor, batching machine, forming machine, gas scrubber, gas purifier, gas circulation and storage device, biomass gas gas generator set (1 power 150kW).

[0013] Drying furnace, dry distillation and pyrolysis furnace and combustion chamber constitute the conveying system and heating system. The drying furnace and the dry distillation and pyrolysis furnace are in a horizontal stacking structure. The drying furnace is located directly above the dry distillation and pyrolysis furnace, and a spiral transmission and agitator driven by a transmission device is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com