Silt pretreatment method for enhancing dehydration property and digestibility of silt

A sludge dehydration and digestibility technology, applied in sludge treatment, biological sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of large area of facilities, long sludge residence time, organic matter removal rate Low-level problems, to achieve the effects of reduced disposal costs, shortened anaerobic digestion time, and reduced sludge transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

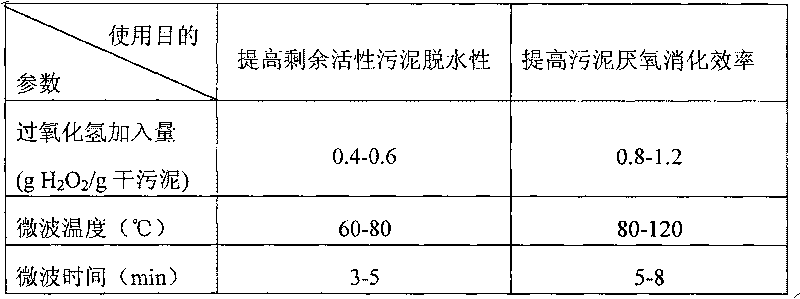

Image

Examples

Embodiment 1

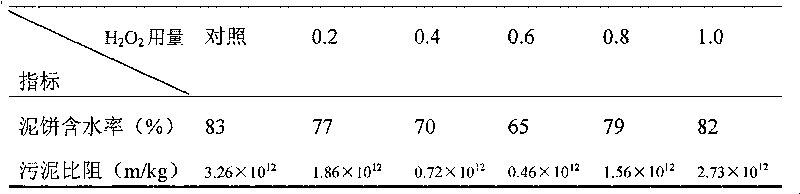

[0020] Embodiment 1, get the surplus activated sludge of certain municipal sewage treatment plant, under normal temperature, add 30% hydrogen peroxide solution (0.2-0.8g H 2 o 2 / g dry sludge), stir and mix evenly, and then radiate the above sludge at a microwave frequency of 2450MHz and a temperature of 80°C for 5min. The control sludge did not receive any treatment. The same amount of flocculant (PAM) was added to all sludge for flocculation and sedimentation, followed by mechanical press filtration for dehydration. The results are shown in Table 1.

[0021] Table 1 Hydrogen peroxide dosage (g H 2 o 2 / g dry sludge) to improve the effect of sludge dewaterability

[0022]

Embodiment 2

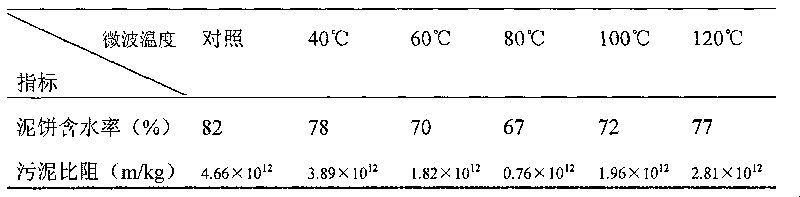

[0023] Embodiment 2, get the surplus activated sludge of certain urban sewage treatment plant, under normal temperature, add 30% hydrogen peroxide solution (0.5g H 2 o 2 / g dry sludge), stir and mix evenly, and then irradiate the above sludge at microwave frequency 2450MHz and different treatment temperatures (40-120°C) for 5min. The control sludge did not receive any treatment. The same amount of flocculant (PAM) was added to all sludge for flocculation and sedimentation, followed by mechanical press filtration for dehydration. The results are shown in Table 2.

[0024] Table 2 Effect of microwave temperature on improving sludge dewaterability

[0025]

Embodiment 3

[0026] Embodiment 3, get the surplus activated sludge of certain urban sewage treatment plant, under normal temperature, add 30% hydrogen peroxide solution (0.5g H 2 o 2 / g dry sludge), stir and mix evenly, and then radiate the above sludge at a microwave frequency of 2450MHz and 80°C for 2-10min. The control sludge did not receive any treatment. The same amount of flocculant (PAM) was added to all sludge for flocculation and sedimentation, followed by mechanical press filtration for dehydration. The results are shown in Table 3.

[0027] Table 3 Effect of microwave treatment time on improving sludge dewaterability

[0028]

[0029] It can be seen from Table 1-3 that, first of all, with the gradual increase of the amount of hydrogen peroxide, the increase of microwave temperature, and the increase of microwave time, the dehydration performance of sludge will increase accordingly. But when the amount of hydrogen peroxide exceeds 0.6g H 2 o 2 / g dry sludge, when the mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com