A kind of kerosene co-liquefaction iron-based catalyst

An iron-based catalyst and co-liquefaction technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, hydrocarbon oil cracking, etc., can solve the problems of poor dispersion and limited activity, and achieve good activity , the use of less, the effect of mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] It is 5wt% according to the metering load of Fe, the mol ratio of Fe, Co, Al, Zn element is 90:5:2.5:2.5, with 24.8223g (0.0893mol) ferrous sulfate heptahydrate, 1.3946g (0.0050mol) seven Cobalt sulfate hydrate, 0.8331g (0.00125mol) aluminum sulfate octadecahydrate, 0.7175g (0.0025mol) zinc sulfate heptahydrate were added to 500mL distilled water to prepare a sulfate solution, and then 100g was added to the sulfate solution with a specific surface area of 600 ()m 2 / g of activated carbon, and the flow rate is 1m 3 / h of air, while adding 1mol / L ammonia solution to keep the pH of the reaction solution between 6.0 and 7.0, react at 38°C for 1.5 hours, discharge the material after the reaction, suction filter and dry in a constant temperature oven at 100°C Dry in medium to obtain a Co-Al-Zn-FeOOH / activated carbon catalyst with a Fe metered loading of 5 wt%.

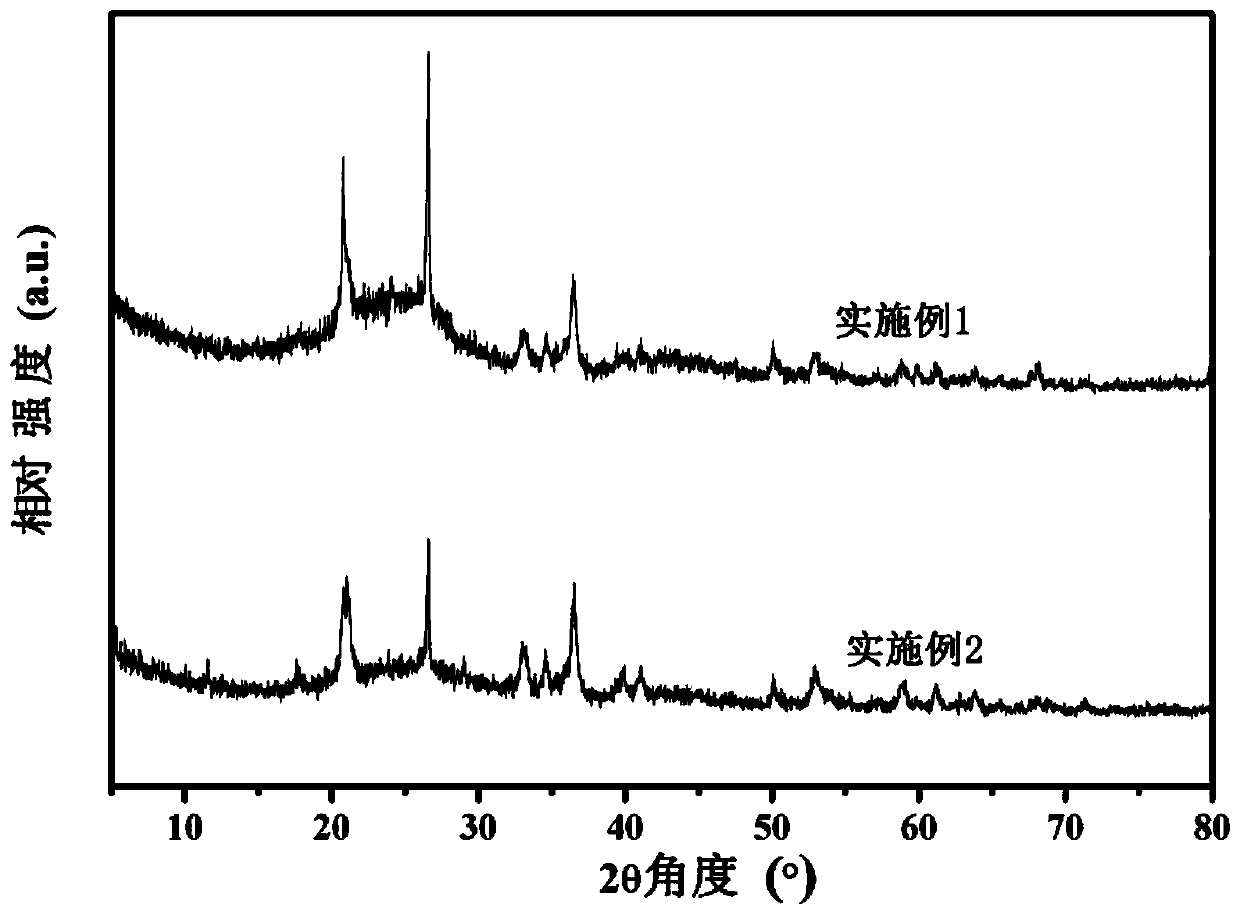

[0027] Depend on figure 1 It can be seen that the obtained catalyst has obvious α-FeOOH characteristic diffrac...

Embodiment 2

[0029] It is 5wt% according to the metering load of Fe, and the mol ratio of Fe, Ni, Al element is 90:5:5, with 248.2232g (0.8929mol) ferrous sulfate heptahydrate, 13.0381g (0.0496mol) nickel sulfate hexahydrate, Add 16.5275g (0.0248mol) aluminum sulfate octadecahydrate to 5L distilled water to prepare a sulfate solution, then add 1000g to the sulfate solution with a specific surface area of 600m 2 / g of activated carbon, and the flow rate is 1.5m 3 / h of air, while adding industrial ammonia water with a mass fraction of 25%, keeping the pH of the reaction solution between 6.0 and 7.0, reacting at 35°C for 2 hours, discharging the material after the reaction, suction filtration and keeping the temperature at 110°C Dry in a drying oven to obtain a Ni-Al-FeOOH / activated carbon catalyst with a Fe metered loading of 5 wt%.

[0030] Depend on figure 1 It can be seen that the obtained catalyst has obvious α-FeOOH characteristic diffraction peaks at 18°, 21°, 26°, 33°, 35°, 37°, ...

Embodiment 3

[0032] It is 5wt% according to the metering load of Fe, the mol ratio of Fe, Ni, Al, Zn element is 90:5:2.5:2.5, with 24.8223g (0.0893mol) ferrous sulfate heptahydrate, 1.3142g (0.0050mol) hexahydrate Nickel sulfate hydrate, 0.8331g (0.00125mol) aluminum sulfate octadecahydrate, 0.7175g (0.0025mol) zinc sulfate heptahydrate are added to 500mL distilled water, are mixed with sulfate solution, then add 100g specific surface area to this sulfate solution 600m 2 / g of activated carbon, and the flow rate is 1m 3 / h of air, while adding 1mol / L ammonia solution to keep the pH of the reaction solution between 6.0 and 7.0, react at 38°C for 1.5 hours, discharge the material after the reaction, suction filter and dry in a constant temperature oven at 110°C Dry in medium to obtain a Ni-Al-Zn-FeOOH / activated carbon catalyst with a Fe metered loading of 5 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com