A device and method for high-value utilization of biomass based on photothermal coupling

A light-heat coupling and biomass technology, which is applied in the direction of biofuels, charging devices, special forms of dry distillation, etc., can solve the problems of low calorific value of products, high energy consumption, and easy coking when heated, so as to reduce energy consumption, The effect of avoiding coking and carbon deposition and improving product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

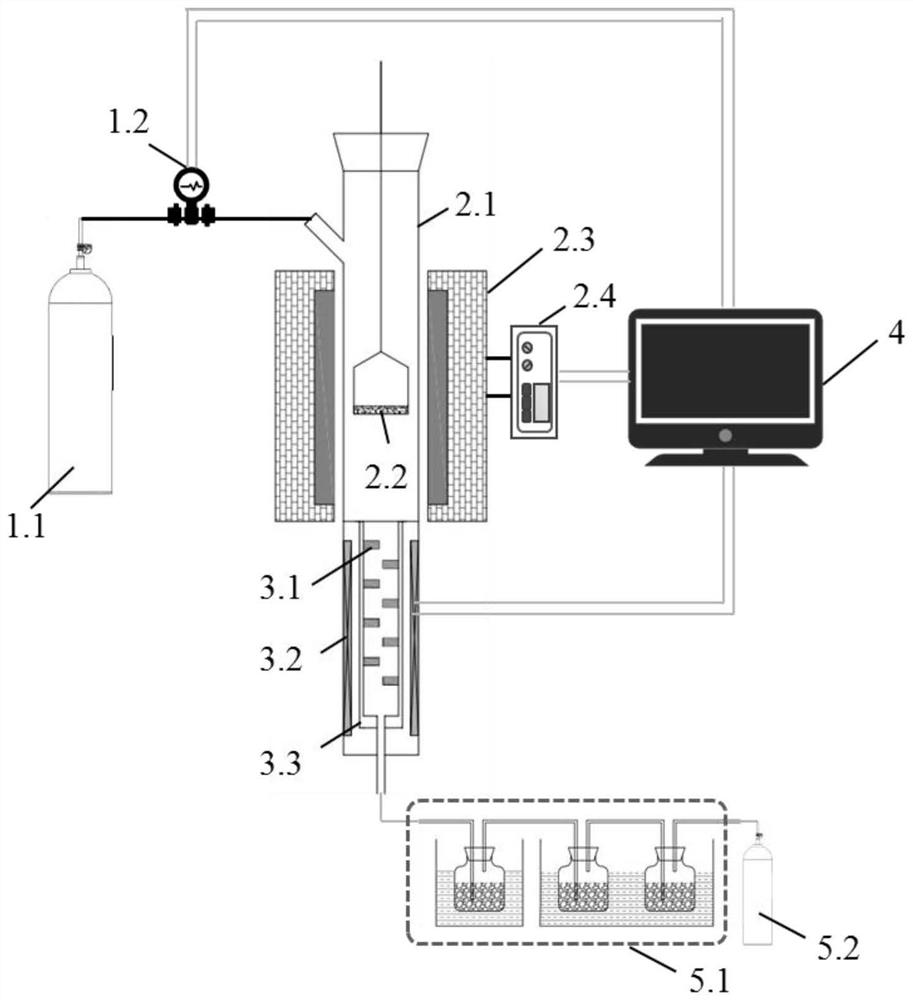

Method used

Image

Examples

Embodiment 1

[0051] a. Place 1g of cotton in the loading basket in advance, match the loading basket with the thermal reactor, place it in the center of the heating device, and connect the thermal reactor, vacuum reactor and integrated light source by means of circular buckles;

[0052] b Use the control unit to control the flow rate of the carrier gas to 200mL / min, use nitrogen as the protective gas, set the temperature of the temperature control device to 300°C, the heating rate is 10°C / s, and the wavelength of the integrated light source is 300nm;

[0053] The light volatile matter and combustible gas obtained from biomass pyrolysis are collected through the condensation collection unit.

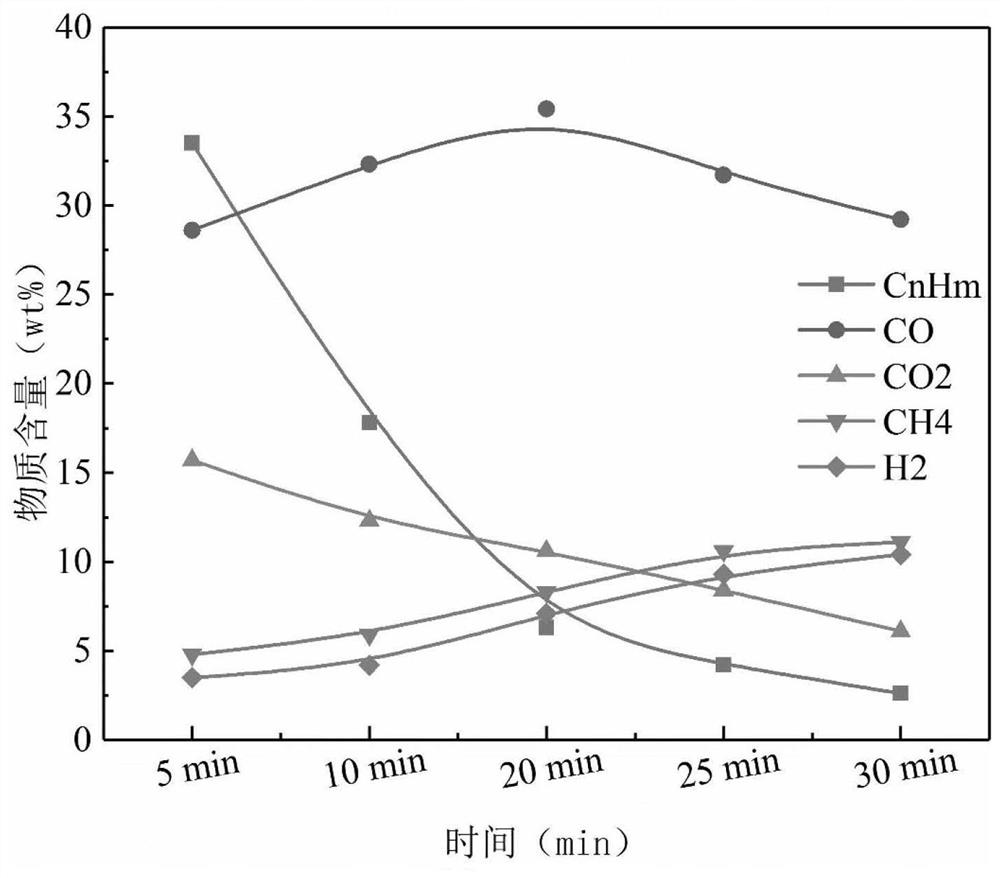

[0054] Sampling and measurement at intervals of 5 minutes, the change diagram of small molecular substance content and flammable gas content in light tar obtained from condensation during this process is shown in figure 2 .

Embodiment 2

[0056] Different from Example 1, the raw material in this example is 1g of corn stalks, the control unit is used to control the flow rate of the carrier gas to 300mL / min, nitrogen is used as the protective gas, the temperature control device is set at a temperature of 350°C, the heating rate is 5°C / s, and the light source is integrated The wavelength is 320nm.

Embodiment 3

[0058] Different from Example 1, the raw material in this example is 1g of cotton, the control unit is used to control the carrier gas flow rate to 400mL / min, the protective gas is argon, the temperature control device is set at 400°C, the heating rate is 5°C / s, and the light source is integrated The wavelength is 350nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com