Supercritical water oxidizing device

A supercritical water oxidation and boundary fluid technology, applied in the oxidation treatment of sludge, chemical instruments and methods, water treatment of fluid flow conditions, etc. Supercritical water oxidation treatment, the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Gravity has a significant impact on the fluid flow and particle movement inside the supercritical water oxidation equipment, which is manifested as affecting the residence time of materials in the reactor and the deposition of particles in the reactor. For pollutants with high solid content (such as municipal sludge, oily sludge, etc.), their own solid content is high, and gravity has a more significant effect on the deposition of particulate matter inside the reactor. For this type of pollutants, it is necessary to design a new type of reactor, so that it can not only ensure the residence time of such pollutants in the reactor, but also effectively use gravity to achieve effective separation of solid particles.

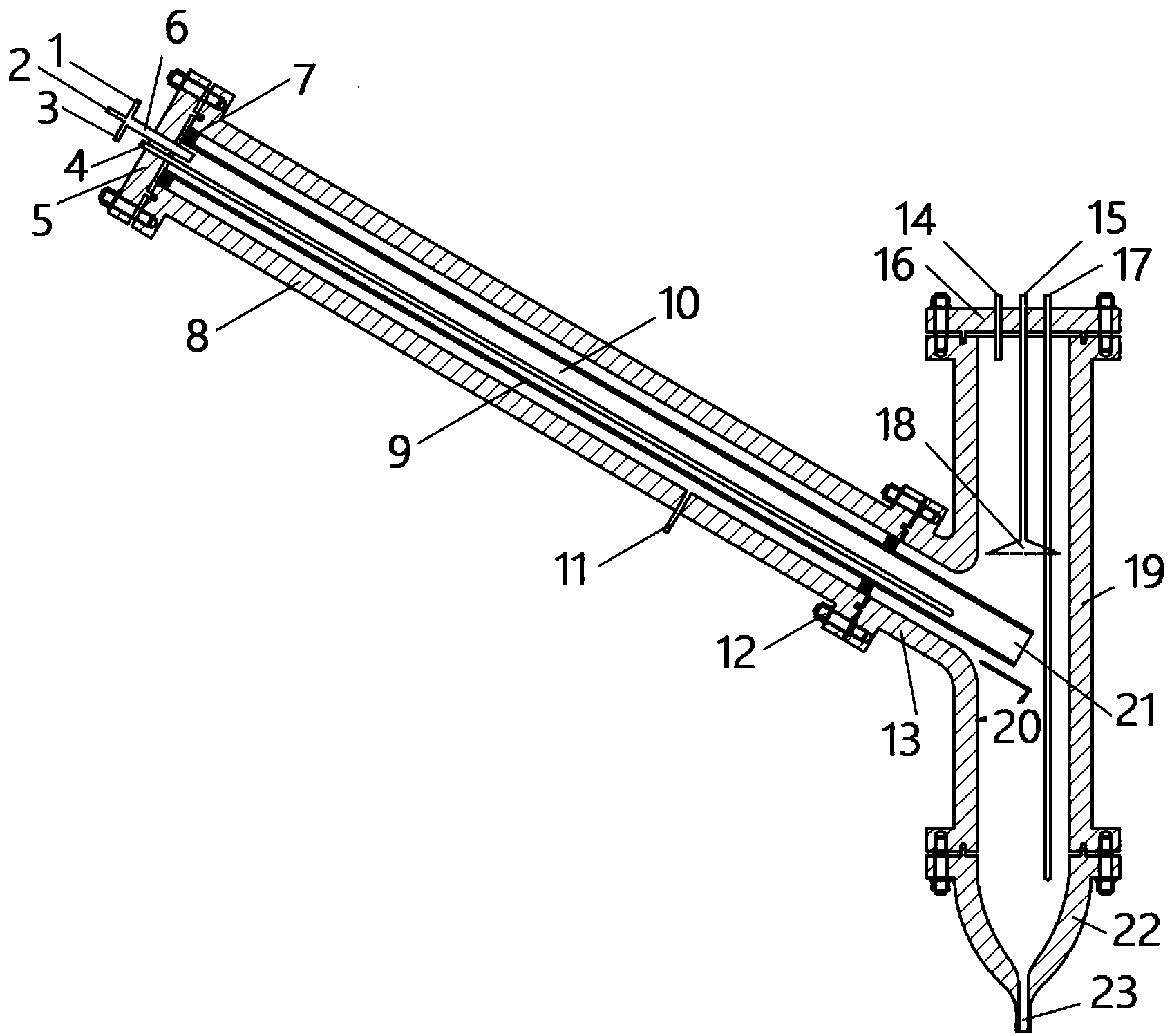

[0021] Please refer to figure 1 , the present invention provides a kind of supercritical water oxidation device, especially a kind of supercritical water oxidation device for treating high solid content pollutants, comprising: a reactor placed on an incline, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com