Small-size supercritical water oxidation reaction system and control method thereof

A supercritical water oxidation and reaction system technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of pipeline blockage, incomplete treatment, secondary pollution, etc., to ensure accurate control, save system costs, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

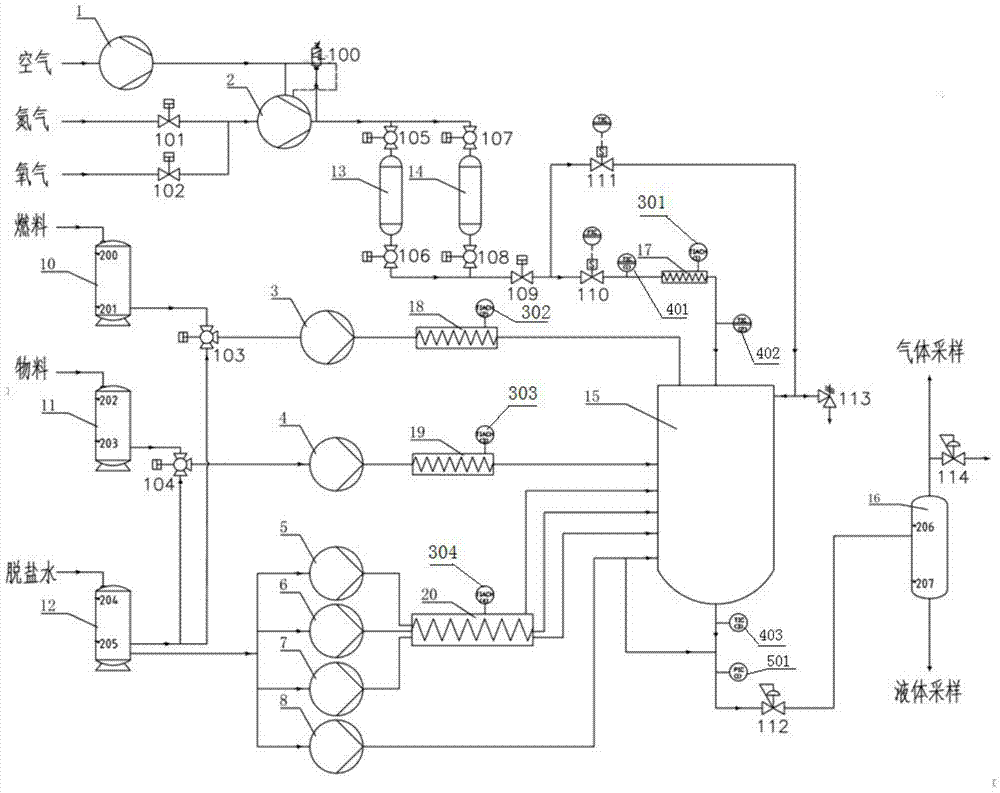

[0055] A small reaction system for supercritical water oxidation, the reaction system comprising:

[0056] (1) Gas pressurization unit: It is composed of air pressurization unit, nitrogen pressurization unit and oxygen pressurization unit. The air pressurization unit includes air passage and air compressor 1 to provide compressed air for nitrogen pressurization unit and oxygen pressurization unit. The high-pressure APS control valve 100 is also connected to the air passage, and the air passage provides air to the air drive end of the air compressor 1 and the ART end of the high-pressure APS control valve 100 .

[0057] The nitrogen pressurization unit includes a nitrogen passage and a gas booster pump connected thereto, a nitrogen storage ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com