Supercritical water oxidation system using air as protecting film and reaction process

A technology of supercritical water oxidation and protective film, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of increasing system operating costs, and achieve the effect of avoiding corrosion and salt deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

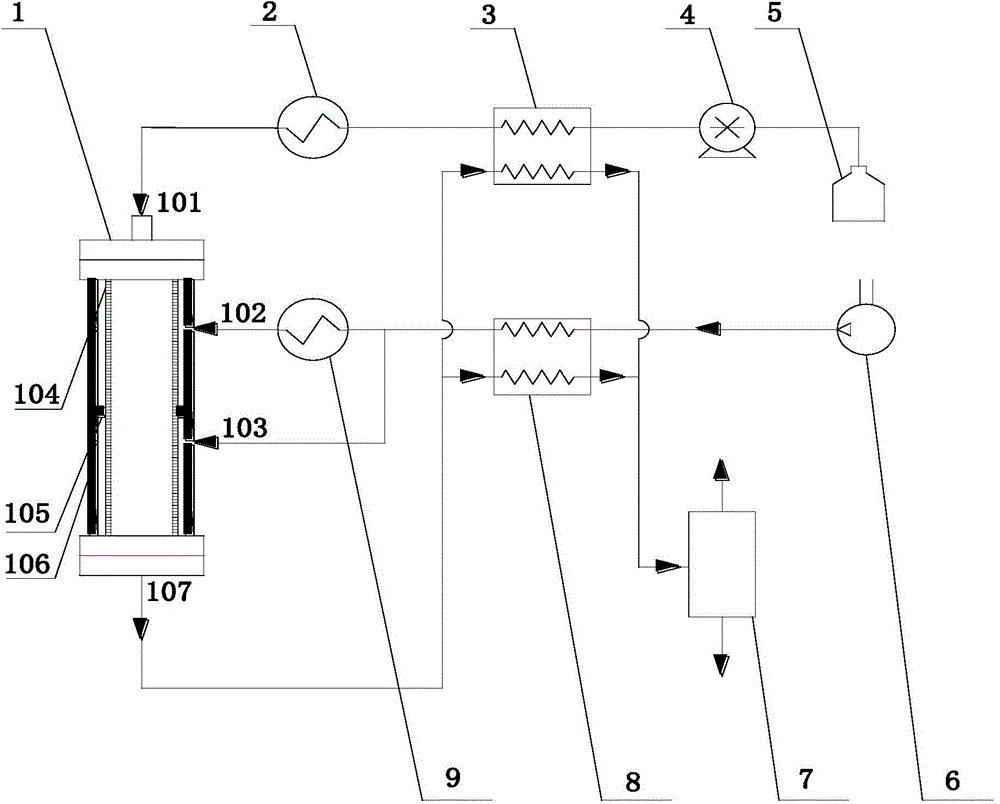

[0028] Please refer to Figure 1 to Figure 2 , figure 1 shows a supercritical water oxidation system using air as a protective film, including a double-shell reactor 1, an organic wastewater input pipeline, an air input pipeline and a reactant discharge pipeline.

[0029] The organic wastewater input pipeline is used to input organic wastewater at a certain temperature and pressure (temperature is 200-370°C, pressure is 22.1-30MPa) to the double-shell reactor 1, and the air input pipeline is used to input and The air required for the supercritical water oxidation reaction of organic wastewater, and the reactant discharge pipeline is used to separate and discharge the reaction products.

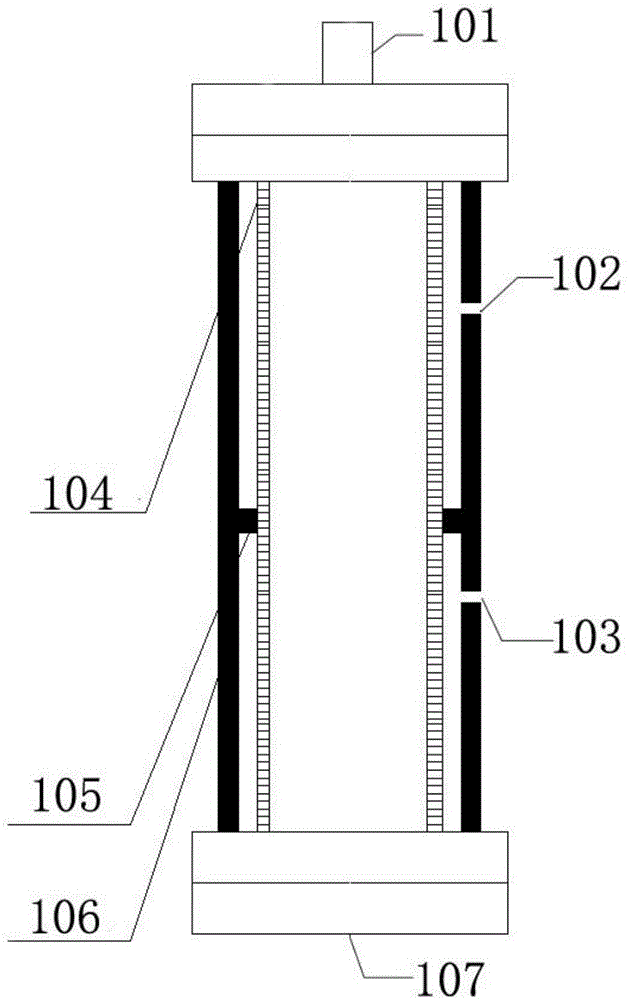

[0030] figure 2 Shown is a schematic structural view of a double-shell reactor 1, the double-shell reactor 1 includes a porous wall 104 on the outside and a pressure-bearing wall 106 on the inside, between the porous wall 104 and the pressure-bearing wall 106 Partition ring 105, the porous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com