Supercritical water oxidation reaction system for obtaining heat supplemented by auxiliary fuel

A supercritical water oxidation and reaction system technology, applied in the fields of oxidized water/sewage treatment, water pollutants, chemical instruments and methods, etc., can solve problems such as equipment blockage, unresponsive fluid desalination treatment, corrosion, etc., to prevent salt deposition and corrosion, reducing system complexity and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

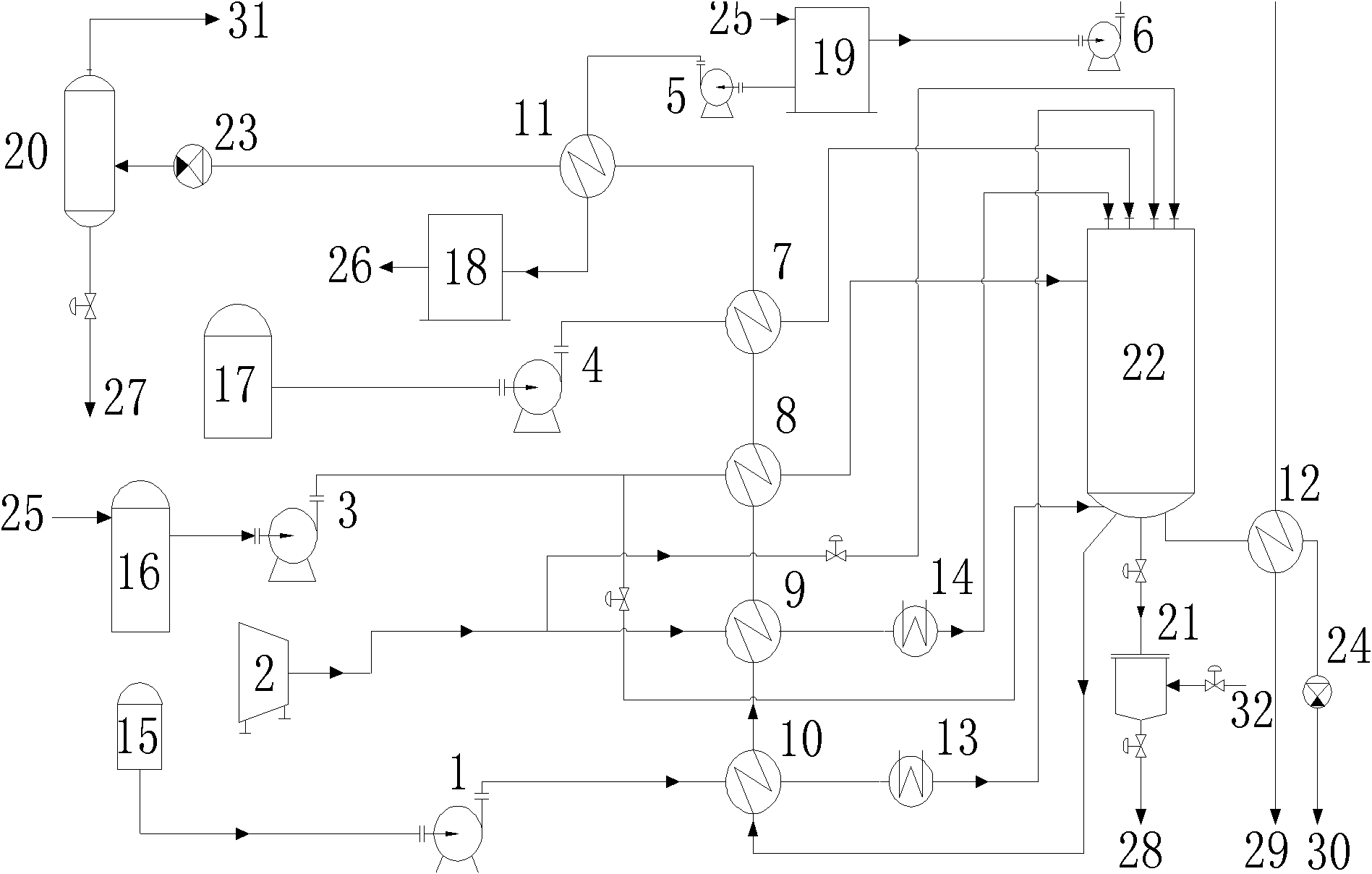

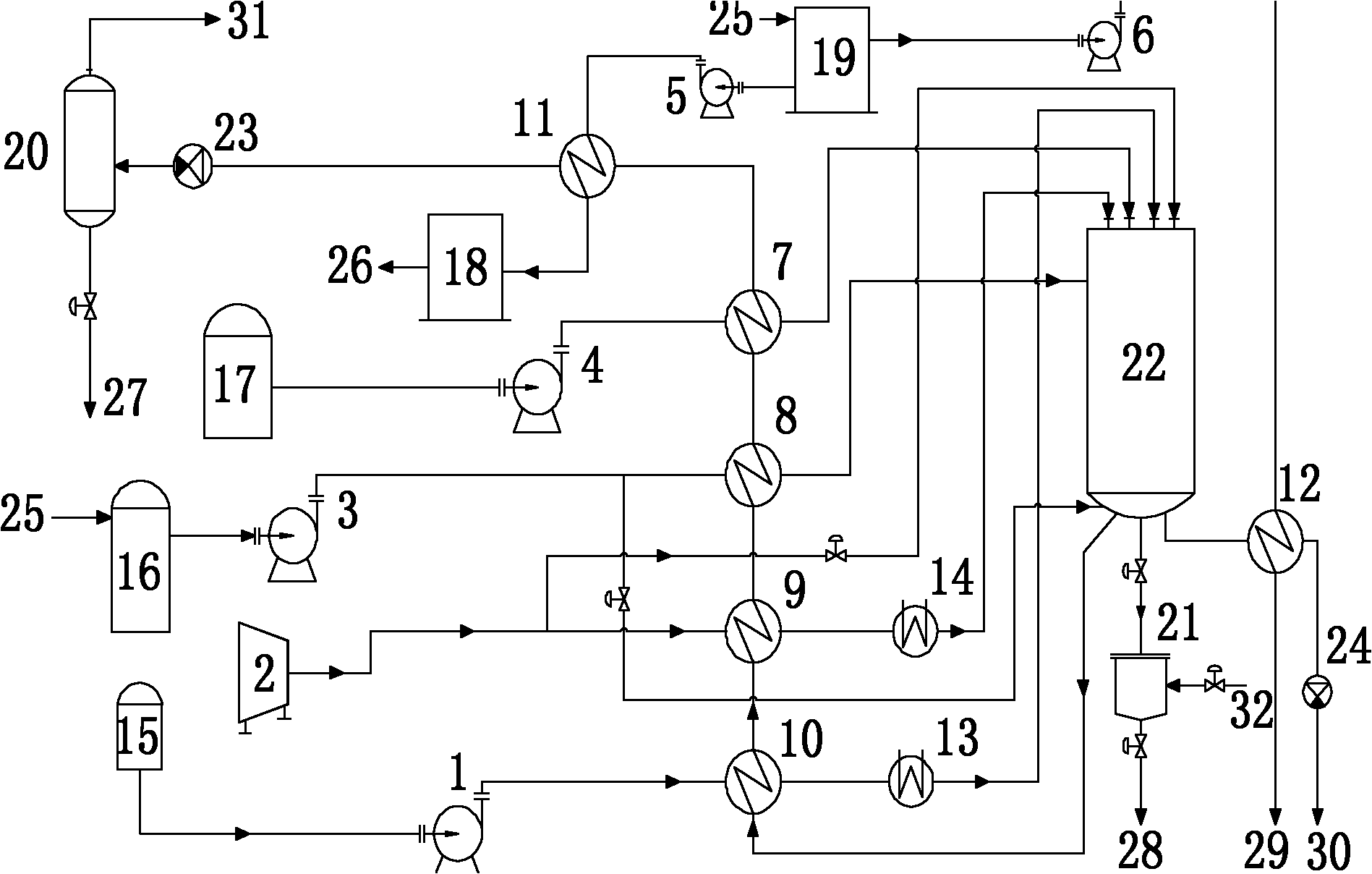

[0025] Such as figure 1As shown, a supercritical water oxidation reaction system using auxiliary fuel to supply heat includes a reactor 22, a material device, an oxidant device, a fuel supply device, a cooling water device and a desalination device. The reaction fluid outlet at the bottom of the reactor 22 is communicated with the inlet of the fourth heat exchanger 10 through a pipeline; the outlet of the fourth heat exchanger is communicated with the inlet of the third heat exchanger 9 through a pipeline; the outlet of the third heat exchanger is communicated with the second heat exchanger through a pipeline The outlet of the second heat exchanger is communicated with the inlet of the first heat exchanger 7 through a pipeline; the outlet of the first heat exchanger is communicated with the inlet of the fifth heat exchanger 11 through a pipeline; the outlet of the fifth heat exchanger is communicated with the inlet of the fifth heat exchanger through a pipeline A back pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com