Multi-circuit heat exchanger

a heat exchanger and multi-circuit technology, applied in indirect heat exchangers, heat exchange apparatus safety devices, lighting and heating equipment, etc., can solve the problems of unsatisfactory refrigerant flow into the other chamber, loss of performance, loss of lubricating oil, etc., and achieve the effect of preventing fluid cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

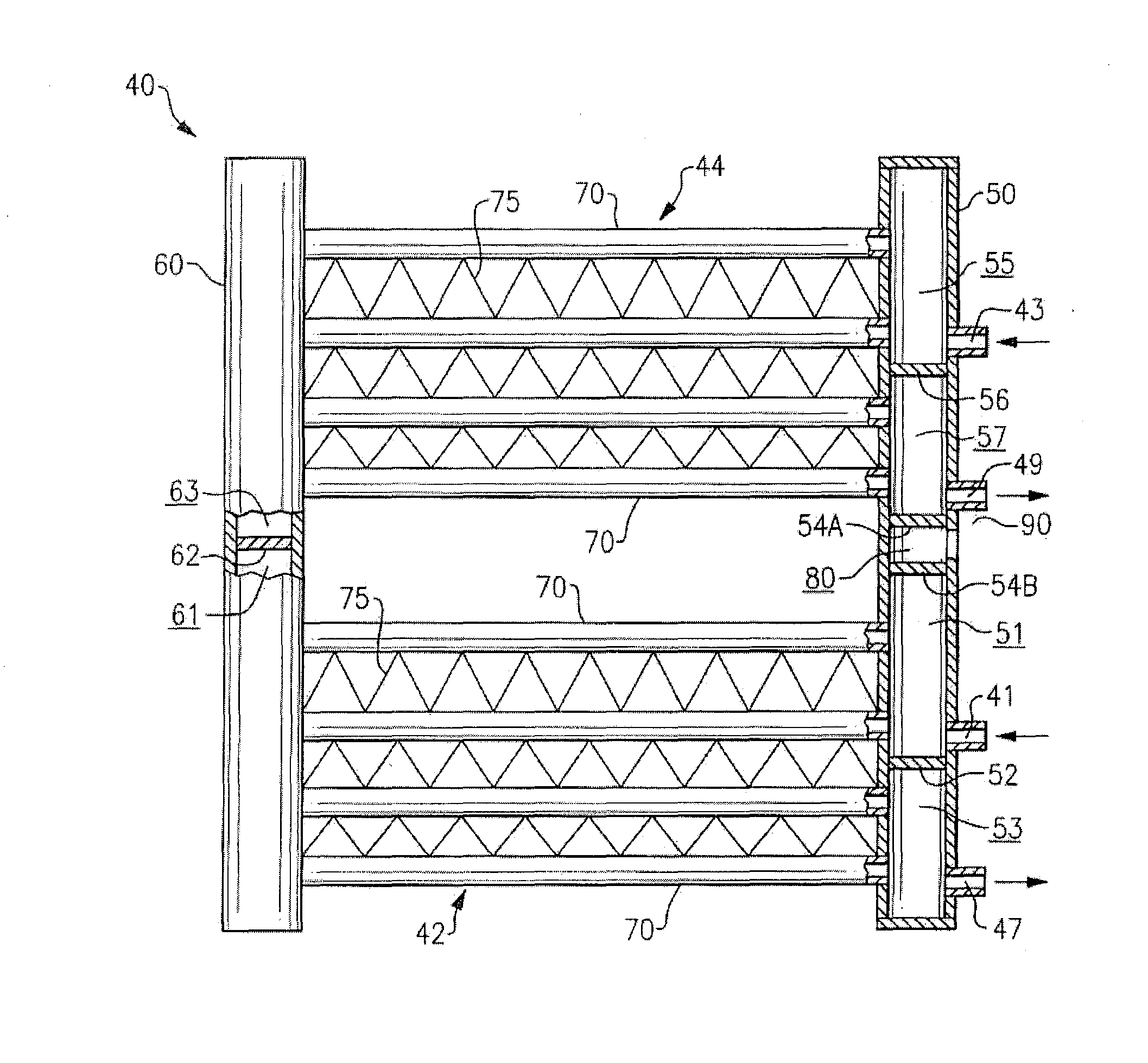

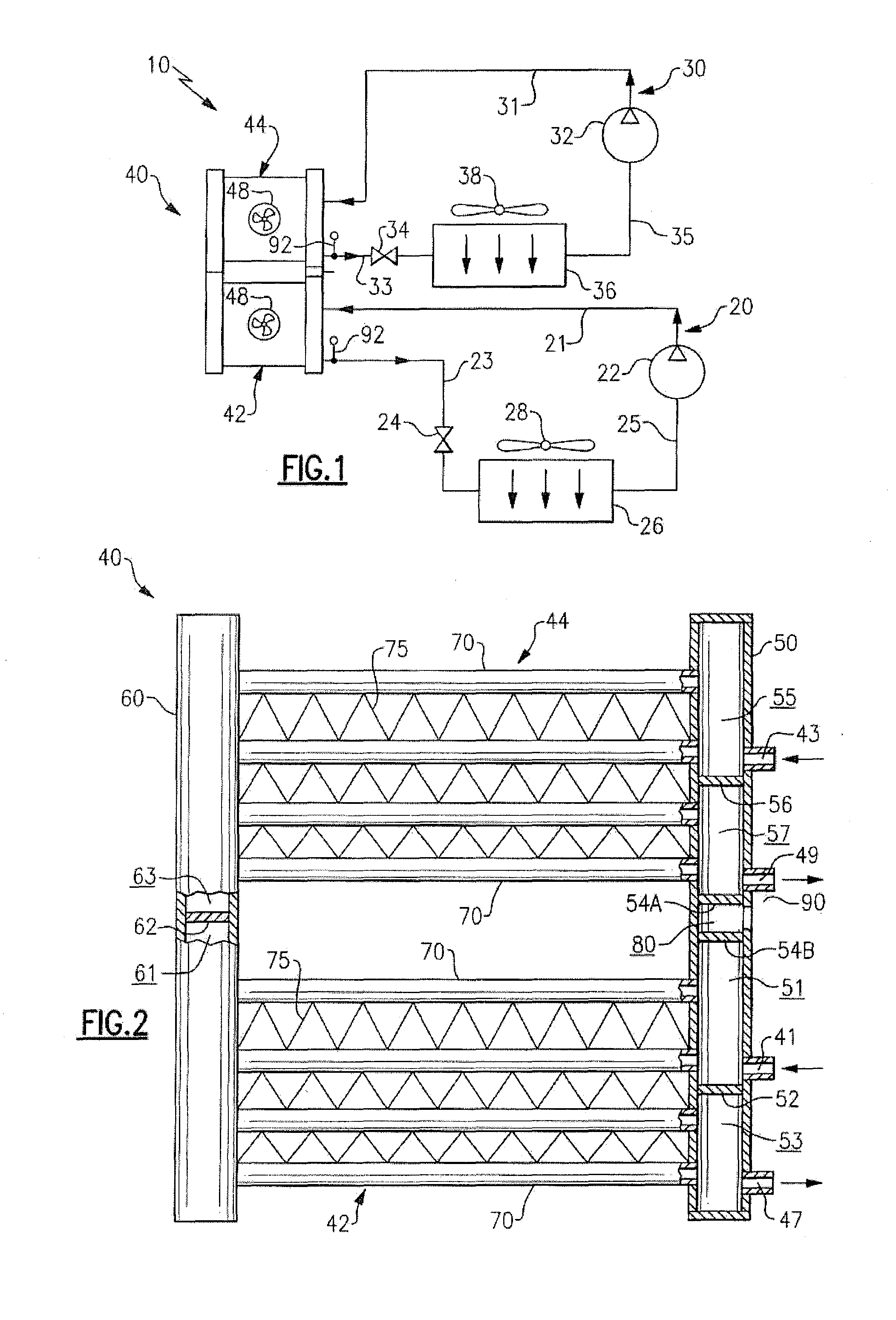

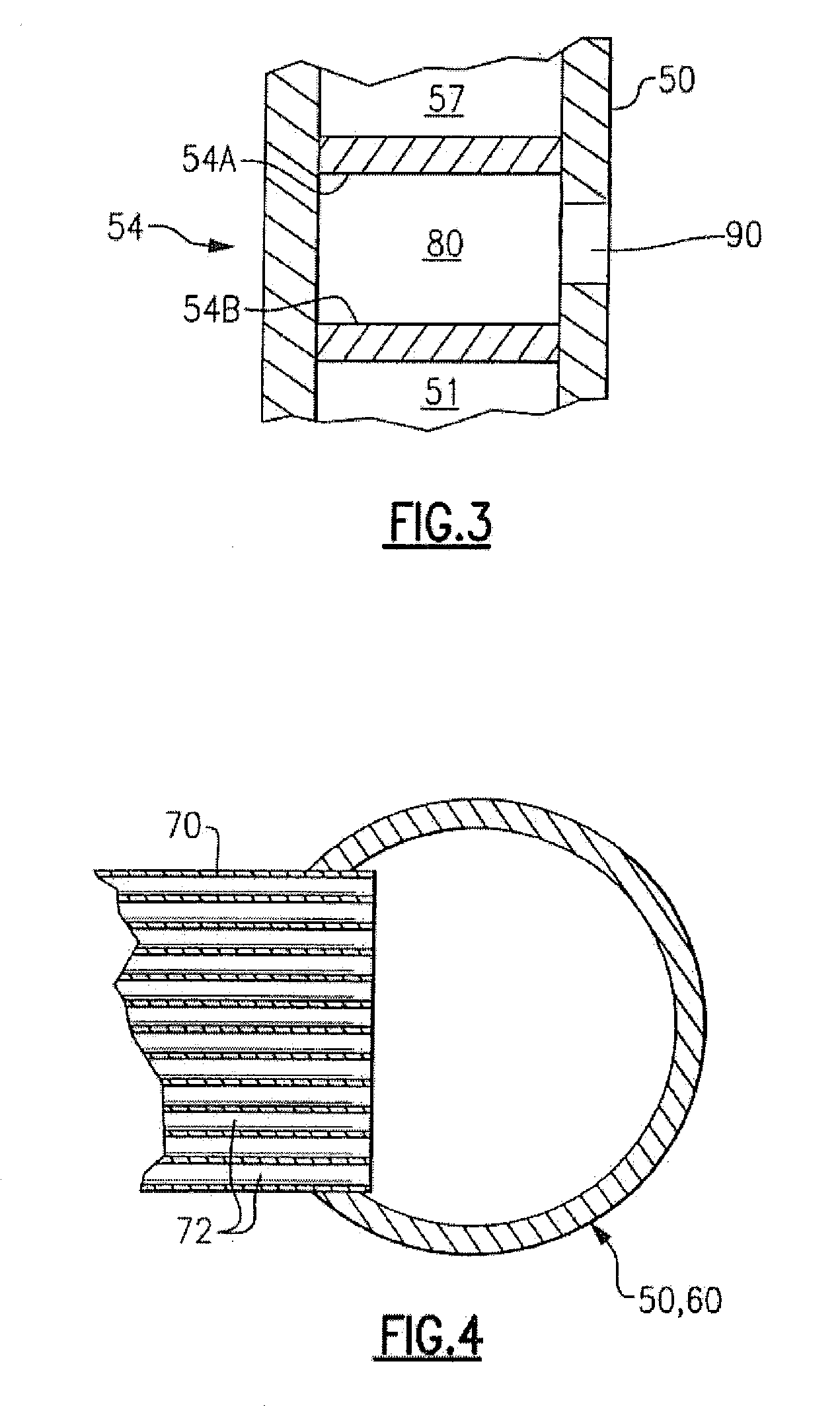

[0017]Referring initially to FIG. 1 of the drawings, there is depicted exemplary embodiments of a multiple circuit refrigerant vapor compression system 10 including two separate refrigerant circuits 20, 30, each of which operates independently of the other under the direction of a system controller (not shown) for conditioning air within separate zones of a climate-controlled space. The refrigerant vapor compression system 10 includes a dual-circuit heat exchanger 40 having a first heat exchange circuit 42 that is interdisposed in the first refrigerant circuit 20 and a second heat exchange circuit 44 that is interdisposed in the second refrigerant circuit 30. The first refrigerant circuit 20 further includes a refrigerant vapor compressor 22, an expansion device 24 and an evaporator 26 connected, together with the first heat exchange circuit 42 of the heat exchanger 40, in a closed loop refrigerant circuit by refrigerant lines 21, 23 and 25. The second refrigerant circuit 30 further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com