Modified heat pipe for phase change cooling of electronic devices

a technology of electronic devices and heat pipes, applied in the direction of heat exchange apparatus safety devices, semiconductor/solid-state device details, lighting and heating apparatus, etc., can solve the problems of low stand alone cooling capacity, low cooling capacity of conventional cooling devices, and failure of conventional heat pipes, so as to increase the volume of working fluid, improve the cooling capacity, and reduce the effect of pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0001]1. Field of the Invention

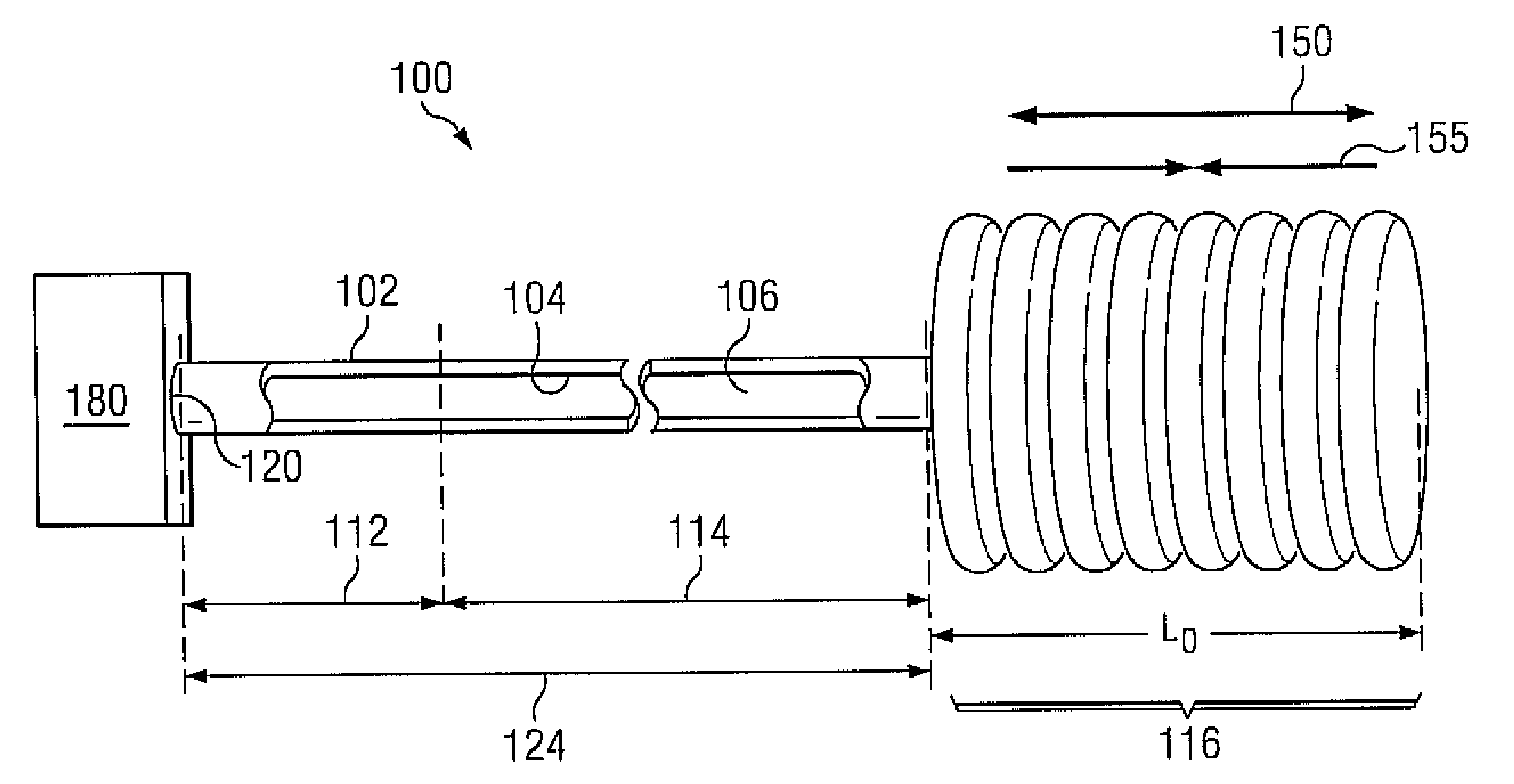

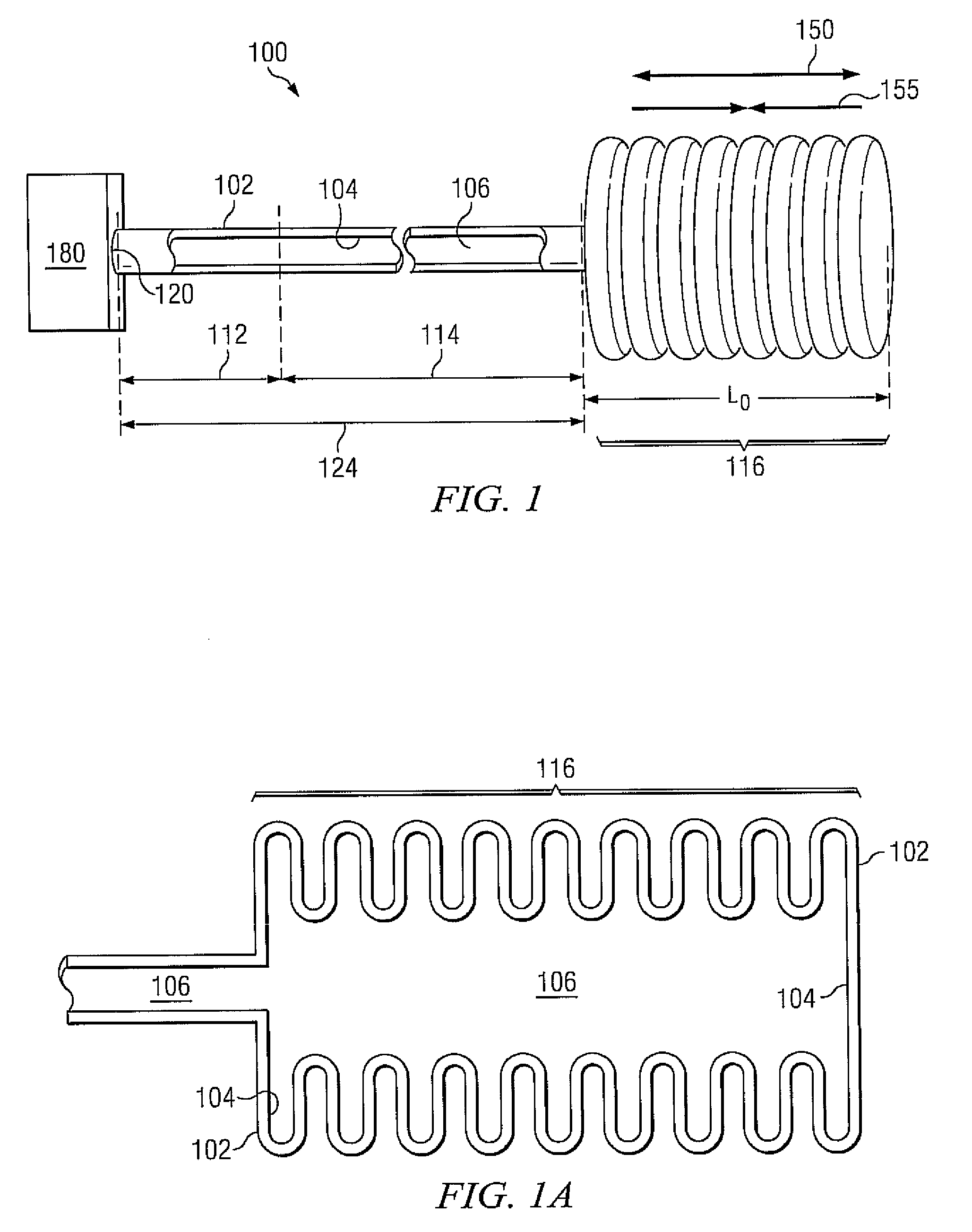

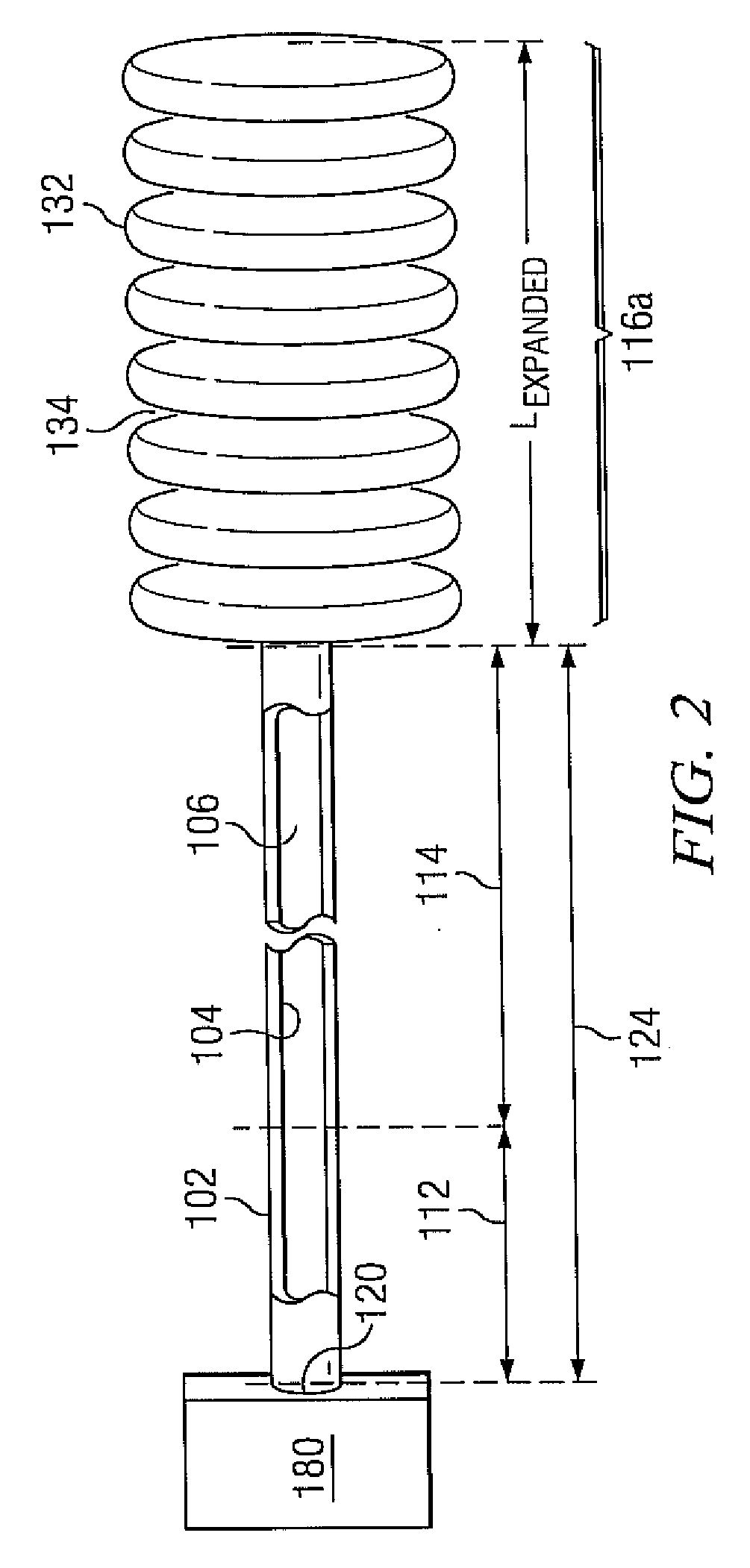

[0002]This invention generally relates to heat transfer components and, more particularly, to heat pipes that include an expandable chamber.

[0003]2. Background of the Invention

[0004]The power density of components used in portable electronics such as cellphones, MP3 players and global positioning systems (GPSs) is increasing as more features are added to the equipment and with the advent of new package technologies such as stacked die, stacked packages, and through-silicon vias (TSV) packages. Additionally, new battery technologies have increased the power capacity, e.g., by about 10% per year. Due to these reasons, the operating temperature of portable electronic devices has increased dramatically. However, due to battery life concerns, these portable electronic devices do not use miniature fans and heat sinks.

[0005]Conventional methods to release the increased heat generated by these devices include the use of heat spreaders, which are either integra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com