Explosive welding process for super-long and super-wide composite boards

A technology of explosive welding and composite plates, which is applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of low local bonding strength and missing edges, etc., to eliminate edge missing and improve interface bonding Strength, the effect of high interfacial bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

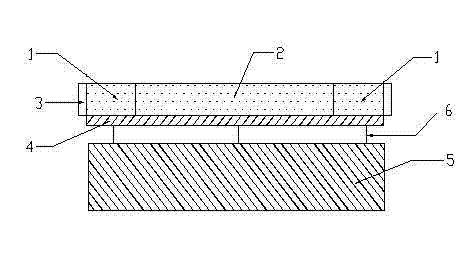

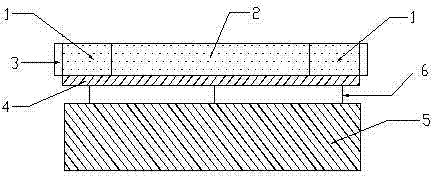

[0026] Such as figure 1 As shown, a super-long and super-wide composite plate explosive welding process, the process steps are as follows:

[0027] 1) Substrate treatment: Substrate 5 is selected as Q345R low-alloy steel plate with a thickness of 40mm, a width of 4060mm, and a length of 8060mm. The substrate is annealed to eliminate its internal stress and improve its shape. The annealing temperature is 670° C. to 690° C. and the holding time is 80 minutes to 100 minutes. After the annealing treatment, level the substrate. The leveling standard is that the vertical and horizontal flatness of the board surface is ≤8mm, and then the leveled substrate is ground and polished until the roughness of the surface to be bonded is Ra≤0.0032mm;

[0028] 2) Doubler board treatment: Choose doubler board 4 as TA2 board, with a thickness of 6 mm to 8 mm, a width of 4100 mm, and a length of 8100 mm. The double boards are spliced according to the specified size, and after the splicing is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com